Andrew Dimelow, principal engineer at Cummins Turbo Technologies, outlines the benefits of conjugate heat transfer (CHT) analysis to predict turbocharger stage performance and component temperatures under select steady and transient operating conditions

Cummins Turbo Technologies routinely uses computational fluid dynamics (CFD) to predict turbocharger behavior and generate performance maps. Typically, this type of analysis is solely concerned with analyzing the aerodynamics of the respective stage and does not consider the effects of thermal exchange across neighboring components.

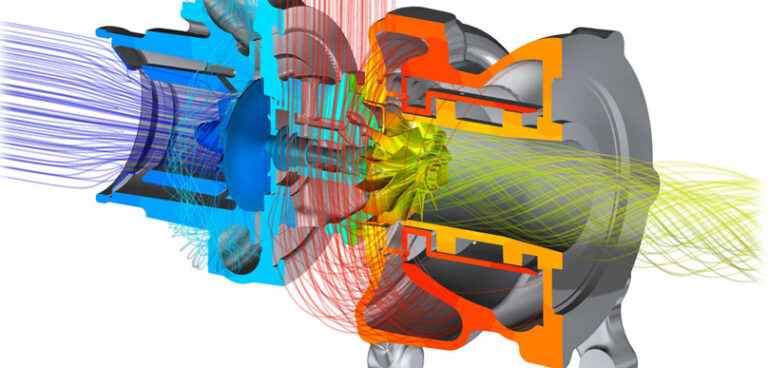

However, with advanced modeling capabilities and access to greater computational resources, it is possible to build a comprehensive CHT model of an entire turbocharger. This multi-domain model is inclusive of housings, core components and stage cavities and provides a tool for generating temperature predictions by simultaneously solving conduction and convection. Of particular interest is the opportunity to explore thermal effects on stage performance under both adiabatic and non-adiabatic conditions. In addition, this analysis approach enables the generation of wetted surface thermal loads which can support subsequent higher resolution damage and thermal mechanical fatigue (DTMF) analysis.

The aerodynamic department at Cummins Turbo Technologies carried out three unique studies which demonstrate the broad application of this analysis approach. Study one was a comparison of adiabatic and non-adiabatic HE200VG compressor performance.

A CHT model of a Cummins non-water cooled HE200VG turbocharger was generated in order to investigate compressor stage performance at several running points when considering heat transfer across the assembly. Efficiency was calculated under adiabatic, non-adiabatic and a ‘heat’ condition where the compression is assumed adiabatic but the calculation is inclusive of heat transfer both pre- and post-compression. The analysis, therefore, was capable of breaking down enthalpy change intervals in the compressor stage.

The results showed compressor efficiency curves at three speeds, and showed a greater difference between peak adiabatic and peak non-adiabatic efficiency at the lower speed (~3%). This value reduced to ~0.7% at the high-speed condition. If the heat efficiency can be considered a truer value of the actual compressor efficiency, the results suggest at lower speeds the adiabatic efficiency is more accurate whereas at higher speeds the non-adiabatic efficiency is more accurate.

This supports the understanding that at lower speeds, temperature effects have a greater impact on efficiency. An enthalpy breakdown shows that less heat enters the compressor stage at the higher speed condition, and the energy that enters before the compression is likely to be as a consequence of the compression itself.

Study two analyzed absolute temperature predictions of HE200VG at rated steady operation and transient Hot Shutdown Event (HSE). A CHT model of a non-water cooled HE200VG turbocharger was generated in order to predict temperatures at critical bearing housing locations under a rated steady operating which initiated a transient HSE. A thermal survey of the turbocharger was completed on an engine test in order to understand the level of error present in the CFD model at both conditions of interest.

Immediately disengaging an engine following a period of high power operation can result in an HSE due to high thermal gradients between housings which causes a thermal soak across the turbocharger. This can generate temperature spikes at sensitive locations and repeated HSEs can lead to oil degradation, component wear and ultimately, reduced service life.

Having a CHT model to predict absolute temperature spikes resulting from an HSE is of significant value as it can enable the evaluation of multiple design concepts.

Results demonstrated CHT steady temperature predictions were an average of 1.6% higher across the piston seal ring thermocouples, an average of 7.9% higher across the turbine side journal bearings, and an average of 1.8% lower across the compressor side journal bearings. CHT maximum HSE temperatures were an average of 9% higher across the piston seal ring thermocouples, 1.4% lower across the turbine side thermocouple locations, and 9.7% lower across the compressor side thermocouple locations.

The level of agreement between the CHT model and thermal survey gives a useful degree of confidence in the purpose of evaluating different design concepts under equivalent modeling assumptions.

Finally, study three looked at the generation of transient thermal loads for increased resolution DTMF analysis of HE300WG turbocharger. DTMF analysis is a finite element analysis (FEA) modeling technique which can predict material failure rates due to cyclical thermal loads and is an important stage in the design process of turbocharger components.

A standard approach to preparing a DTMF analysis utilizes a combination of transient thermocouple data from an Accelerated Thermal Cycle Test (ATCT) and constant heat transfer coefficients in order to generate thermal boundary conditions. Thermal and structural FEA analysis is subsequently performed over a number of ATCTs to generate inputs for the DTMF predictions. The accuracy of the DTMF analysis is therefore significantly influenced by the accuracy of the absolute temperatures and thermal gradients calculated in the thermal FEA model.

CHT analysis can be used to simulate the transient ATCT in order to generate increased resolution thermal inputs on stage wetted surfaces and will export individual nodal heat transfer coefficients and wall adjacent temperatures at each thermal load step.

Results of the tests showed that CHT temperatures compared well against thermal survey for the ATCT duration. This gave a reasonable level of confidence in the generated thermal loads to be applied to the DTMF analysis. The CHT-supported DTMF analysis vastly improved the predicted failure cycles with the average prediction ratio calculated as 1.65 as opposed to 465 using the standard DTMF boundary conditions.

This study underlines the importance of the suitability of thermal loads to the accuracy of predicted failure cycles from a DTMF analysis and demonstrates a valuable application of conjugate heat transfer analysis.

For Cummins, the paper demonstrates an approach for applying CHT analysis to a range of steady and transient operating scenarios for predicting turbocharger performance. Results from all three studies provide confidence that CFD can be introduced into the design cycle of a turbocharger with respect to thermal management considerations as well as aerodynamic optimization. This gives the opportunity to arrive at optimal designs faster with reduced requirement for costly physical testing.