APTi investigates how the application of AI and ML techniques is helping to boost the efficiency of battery technology.

Lithium-ion batteries have seen huge improvements since Sony first commercialized the technology in 1991. However, relative to combustion technology and fossil fuels, they are still found wanting. Customers are demanding greater range and faster charging, while cost and supply chain pressures (not to mention weight) are placing an effective cap on pack capacity. With truly game-changing, next-generation battery chemistries still some way off, it therefore falls to engineers to optimize what is already available.

This refinement can take many forms, from tweaking existing chemistries to improving the design – such as cooling capabilities – of packs as well as their management. Across all these development paths, the implementation of new techniques, particularly those harnessing machine learning (ML) and artificial intelligence (AI), are helping engineers squeeze more from less.

Cell manufacturers and those involved in researching new cell chemistries and designs make substantial use of various types of AI- and ML-based tools – for example, to discover and assess promising new materials for use as electrodes and electrolytes. Fascinating as this research is, it falls outside of the scope of this article. Instead, we will focus on some of the tools deployed directly in the automotive sphere, specifically those aiding the design and operation of battery packs.

Building blocks

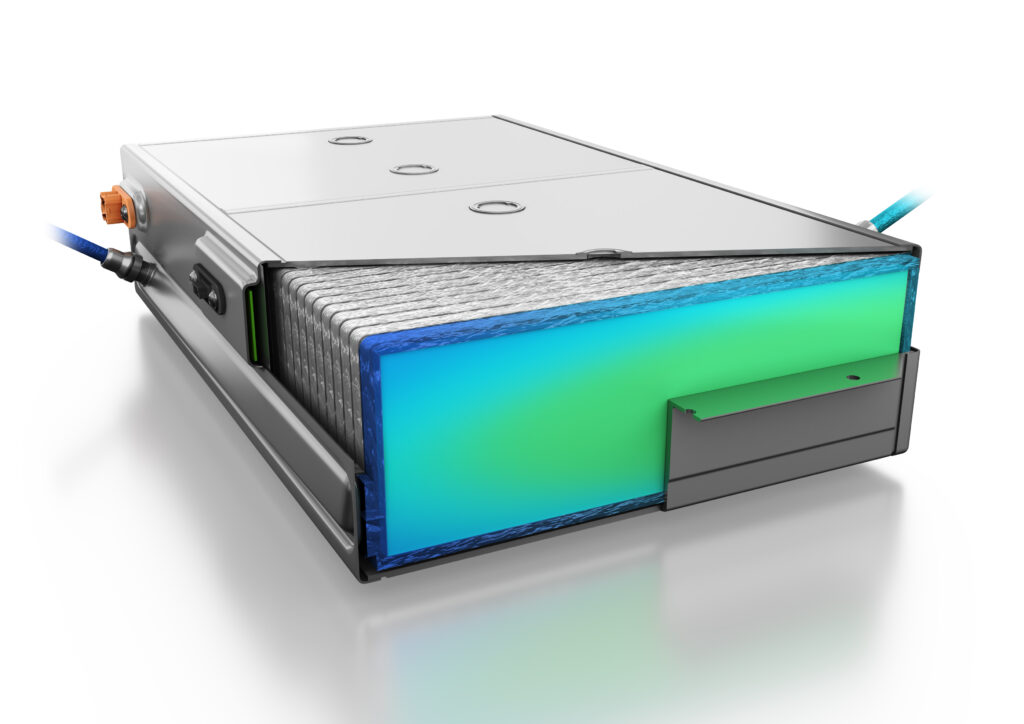

The starting point for any vehicle battery is the creation of a mathematical model of the pack, considering various elements including cell behavior, mechanical constraints and thermal requirements.

When creating a pack system model, the first building block is an electrochemical model of the cells being used. These models range from relatively simple to very complex, depending on how many factors they consider, such as the influence of mass transfer rates on the reactions taking place, or differences in concentration of the electrolyte at reacting sites.

The myriad other multiphysics processes in a battery must also be considered, from fluid and current flows to the effects of temperature variations. The end result should, in theory at least, enable a pack to be run as close as possible to its potential maximum energy or power density in a safe and reliable manner. However, this is not the case in practice and battery capacity is often left on the table due to the need to account for the constraints of outlier use cases.

It is a phenomenally complex task to simulate and test every possible combination and layout of cells to find which best suit a given demand and work well with a vehicle’s cooling systems and other elements.

Fortunately, several software companies have developed dedicated packages that make the process less daunting. Increasingly, these harness AI and ML to speed up the process and enable greater optimization at a pack and cell level.

Generation game

French software company Dessia has developed what it calls a generative engineering software framework that relies on two main strands: a systems-based modeling approach coupled with AI to explore various potential design avenues. These tools can be applied to a host of applications but are particularly well suited to the design of battery packs.

“The systems modeling approach ties together modeling, design rules and requirements – which can be either a purely functional model or 3D,” explains company founder Pierre-Emmanuel Dumouchel. “We have some smart tools to help place components within a constrained environment, for example.”

This model stage is where elements such as the architectural constraints of the vehicle, required performance parameters, cell characteristics and thermal targets are defined. The quality of input data is of utmost importance here, encapsulating elements such as the cell model and thermal coefficients for cooling media and the like. If this source data is not reliable, the outputs from the AI will not be reliable either.

The next stage involves the use of two forms of AI. The first are known as design tree algorithms and are employed to generate hundreds or even thousands of design solutions within the predetermined parameters, which are steadily refined down to perhaps a couple of hundred. A statistical AI-based approach is then applied to refine the final options.

For a given design problem, in this case a battery pack, Dessia has developed a variety of building blocks to create ‘engineering bots’ – generative processes that are specific to the task at hand. “Those building blocks have been developed as a starting point from which our clients can develop their own bots, where they add their own rules and knowledge,” highlights Dumouchel.

Executing this type of process would normally require a dedicated team of data scientists and AI engineers. However, as is the trend in many areas of engineering software, Dessia has developed an interface that does not require specialist knowledge of AI and enables easy integration into existing engineering workflows.

Giving an example, Dumouchel says, “A manufacturer may have a library of cells, from different manufacturers, and that could be the entry point for a bot: looking at the different cells in the library and then generating different pack layouts, respecting all the different layouts while respecting the thermal and physical constraints.”

However, that is not the end of the line for Dessia’s software. Once testing has begun on physical packs, this data can be used to refine the AI, enabling an almost continuous process of optimization.

There are several other applications with varying levels of complexity that can be used to achieve similar results and can be incorporated into common modeling platforms such as MathWorks. For example, Electra Vehicles offers its EnPower package, which uses a cloud-based application with a web interface to give access to cell libraries. It can rapidly simulate different layouts and drive cycles, with the results exportable into packages such as MATLAB.

These solutions from Dessia and Electra, as well as similar tools arriving on the market, do not obviate the need for complex, multiphysics simulation and physical testing of final designs. What they do enable is an optimal solution to be arrived at more rapidly, with a reduced computational workload (though the up-front requirements to generate training data are still substantial).

Lifetime optimization

Beyond the initial pack design and development stages, AI and ML are increasingly being used in BMS. When combined with accurate digital twins, the correct application of these tools enables greater flexibility of operation and thus better optimization of a pack throughout its life. For example, WAE (formerly Williams Advanced Engineering) recently unveiled its Elysia battery intelligence software.

This combines two distinct elements – Elysia Cloud Platform and Elysia Embedded – which lean on the company’s experience in high-performance batteries for motorsport and automotive use, machine learning, data science and electrochemical modeling – to squeeze more out of existing battery solutions. WAE claims its software system enables flexible management of a battery system, moving away from the constraints of operational parameters determined by preset data tables.

Key to this approach is having an in-depth understanding of each cell, which is a vital element of a pack’s digital twin. As Tim Engstrom, technical lead on the Elysia project, explains, “We don’t view the battery cell as a black box. Traditionally, you would buy a cell, it would come with a datasheet and the manufacturer would say, ‘This is the limit you must not exceed.’ But that datasheet doesn’t give you an optimized insight into how you should use that cell in order to maximize performance.”

Key to this approach is having an in-depth understanding of each cell, which is a vital element of a pack’s digital twin. As Tim Engstrom, technical lead on the Elysia project, explains, “We don’t view the battery cell as a black box. Traditionally, you would buy a cell, it would come with a datasheet and the manufacturer would say, ‘This is the limit you must not exceed.’ But that datasheet doesn’t give you an optimized insight into how you should use that cell in order to maximize performance.”

Instead, WAE creates its models based on the individual components and reactions within the cells of a particular pack. “That includes testing each half of the cell, testing the anode and the cathode. Then, when we put these into the battery management system, we can see in real time which part of the cell is limiting performance.”

This is an entirely software-based approach, relying on standard temperature, current and voltage sensors. “We’re creating these models based on testing in our lab, and then we turn it into this very lightweight set of equations that we can actually run in real time on the BMS,” says Engstrom.

This approach to BMS is particularly beneficial when determining the state of health (SOH) of a pack. “The SOH error in current automotive packs can be as much as 10% of the total capacity of the battery,” Engstrom says, noting that, “The standard means of containment within the industry is reserve capacity that you deliberately try not to use, so that you’re not going to get that estimation wrong.”

WAE’s answer is to use adaptive algorithms that monitor a battery’s use profile throughout its lifetime. “Take, for example, fast-charging,” says Engstrom. “Rather than having a static, fast-charge profile through the life, we adapt that according to the type of degradation that’s occurring within that battery.” Importantly, the models rely on probabilistic techniques to judge the SOH at various stages of a battery’s life. “The key to that is knowing where to look in the data. We can see the health of that battery in a multidimensional way.” The result, WAE states, is an impressive up to 30% increase in usable capacity on existing automotive battery packs.

Big data

Beyond the embedded capabilities, the cloud element of Elysia brings the ability to harness big data at a fleet level and deploy considerable computing resources to apply complex AI and ML techniques. This can be used to refine insights into factors such as unforeseen cell degradation.

Engstrom highlights that even seemingly identical cells from the same batch can behave in quite different ways. While most will display very linear degradation profiles, a small number hit a ‘knee point’ at around 80-85% SOH, where the rate of degradation rapidly accelerates. By using more varied data than simple capacity, Engstrom says that Elysia can identify where cells in a pack might be exhibiting these characteristics, combining inputs to create virtual sensors. Armed with this insight, it is then possible to introduce mitigations into the BMS to try to prevent wider problems arising.

This ability, coupled with BMS updates over the air, means it is possible to create a personalized BMS for each vehicle, accounting for not only cell degradation but also the varied use profiles of the same vehicle when in different customers’ hands. Engstrom explains, “Right now, when an auto maker launches a vehicle, they effectively have to engineer around, let’s say, the worst 2% of customers.”

The latest developments promise to unlock far greater potential from batteries. It is still early days for AI-driven, self-learning BMS, but their potential to improve EV performance without requiring a revolution in hardware is certainly promising.

Artificial intelligence

AI and ML are much-abused terms. What do they actually mean? The original meaning of artificial intelligence is presented in the Turing Test, as defined by Alan Turing, the renowned British codebreaker, mathematician and pioneer of modern computer science. In the late 1940s, Turing proposed the idea of a computer capable of learning from experience. In an unpublished 1948 paper titled Intelligent Machines, he introduced concepts such as neural networks, which have become fundamental components of modern AI.

Turing’s test to determine true AI relies on a human interrogator, a human assistant (who aids the interrogator) and a computer. The interrogator can use a keyboard to ask the computer an unlimited number of questions covering various topics. If the computer manages to deceive a sufficient number of interrogators, it is considered to possess intelligent thinking. No AI system has come close to passing a pure Turing test but this does not imply that AI is merely a marketing gimmick or lacks practicality.

Moving ahead to the 21st century, machine learning has emerged as a powerful form of AI that makes predictions based on data. It can be categorized as either weak or strong. Weak AI is designed to perform specific tasks while strong AI encompasses general AI and super AI. General AI refers to an AI system that possesses intelligence equivalent to that of humans, while super AI denotes an AI system with even greater intelligence. However, the notion of general AI remains purely theoretical for the time being.