The move away from fossil fuels is something that, in general, meets very little resistance. We know that atmospheric CO2 is causing climate change and that we should prevent this problem from getting worse. However, as with many aspects of modern life, opinions are polarized about the best sources of energy for the transportation sector. There is a great deal of merit in saying that the best use of electricity is to charge batteries and then discharge them via an electric motor to propel a vehicle. Perversely, this makes most sense when our renewably generated electricity does not meet all our electricity needs.

At the point when instantaneous renewable generation exceeds demand, what should we do? Charge huge batteries connected to the grid, or produce a fuel that can be used for combustion, either in a power station or in road transportation? When we have an excess of generating capacity, the electrolysis of water to produce green hydrogen will be possible on a much larger scale. The answer depends partly on the application – for airlines, the EV airplane is a long way off. Propulsion using synthetic aviation fuels and then hydrogen seems more likely to happen in the medium term.

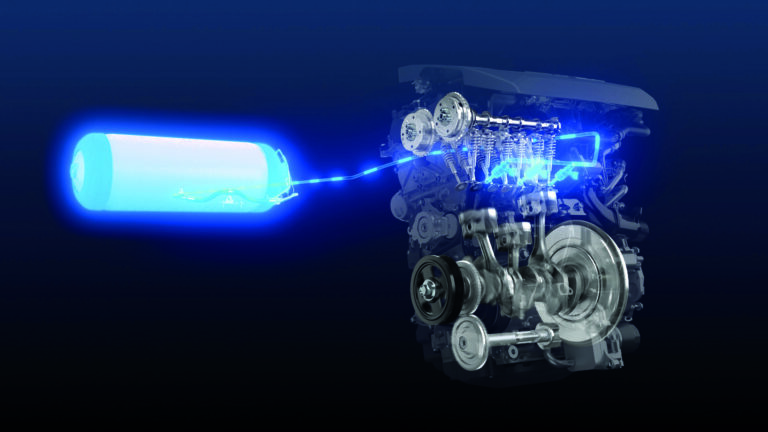

There are many companies, both new and long-existing, that have heavily invested in the pure EV solution for transportation and decry the use of electricity to produce combustion fuels. However, there are also several automotive companies that are taking a more agnostic approach and developing a number of possible solutions including battery EVs, hybrids and hydrogen combustion. We have only to look at relatively recent news stories to see that companies as diverse as Toyota, Renault/Alpine, Cummins, Yamaha, JCB, Kawasaki, Suzuki and Mazda are looking at hydrogen combustion. These companies are not ‘institutionally stupid’, so they are looking at alternatives to battery EV because they believe that such solutions have technical merit.

Car companies are pragmatic and their shareholders want them to make money. If making engines no longer makes money, they will stop. None of these OEMs are irreversibly wedded to the combustion engine or are the victim of their own blind devotion to pistons and crankshafts.

Other specialist powertrain developers, such as Pipo Moteurs, AVL and Mahle, are either building hydrogen-fueled engines or helping other engine producers and users develop them.

Hydrogen can easily be obtained by the electrolysis of water, although that is not the process by which most of it is produced at the moment. Since our electricity supply is relatively ubiquitous geographically, so could be electrolysis plants for the production of hydrogen. Even in a small wind farm, one or more turbines often remain motionless. We could presently be running these oft-motionless turbines and storing the energy either in batteries or producing hydrogen, but we don’t.

It is beyond the scope of this article to look into the methods by which hydrogen is currently produced, whether it would be better used in a fuel cell, or if it has merit as a road fuel at all. From the development activities of automotive companies of all sizes, we see that several think that hydrogen has a future. There is also a large body of technical knowledge in the public domain on this subject.

Why the interest?

Hydrogen can be employed in combustion engines of all types, from pistons to gas turbines. While the internal combustion engine has made big advances in efficiency in recent years, it remains inefficient as an energy conversion device compared with the electric motor. Merits of the hydrogen IC engine are that we understand how to produce such machines cost-effectively, how to make them relatively reliable, and they are very easy to recycle at end of life as they are very easily divided into their constituent parts and materials.

There will naturally be those who rail against hydrogen combustion because of a perceived NOX problem, simply because nitrogen is exposed to combustion. NOX formation is largely a result of temperature. Hydrogen burns over a very wide air-fuel ratio and can be burned very lean, reducing combustion temperatures and therefore NOX production. For example, Oikawa et al1 show data for lambda= 4 and 4.5.

The use of hydrogen in IC engines is very much a nascent technology in many ways, and the infrastructure to support adoption is one of them. I have refueled a hydrogen vehicle and it was totally uneventful. Attaching the hose was a little more involved than refueling with gasoline or diesel but also less smelly. If we are to adopt hydrogen as an alternative net zero solution to the battery or fuel-cell EV, then we also have to provide refueling infrastructure, and the fuel.

Combustion

The words ‘internal combustion’ are, in some areas of the automotive industry, quite unpopular, and there is a reluctance to divorce the automotive ICE from the mostly fossil fuels they have burned for more than a century. It is the fuel that is the enemy, not the engine. Those who are against any form of combustion, having rightly pushed for a significant reduction in CO₂ emissions, now protest against NOX. Again, the point that NOX emissions should be further reduced is widely accepted, even in light of very significant reductions in recent decades. However, the assumption that combustion leads to significant NOX emissions should not go unchallenged.

NOX is the result of high-temperature combustion, and exhaust gas recirculation (EGR) has been very effective in automotive engines in diluting the unburned charge and thereby reducing NOX emissions. NOX is also dramatically reduced by lowering combustion temperature. Those who point toward the high energy content and rapid combustion of hydrogen and assume that combustion temperatures (and therefore rates of NOX formation) are necessarily very high are wrong. Hydrogen engines can easily run at equivalence ratios (lambda) of 2 or 3, with such lean mixtures a very effective way of controlling combustion temperatures and therefore NOX emissions.

One engine manufacturer I spoke to, who has gone through several iterations of hydrogen engine designs, sees NOX emissions as a non-issue given the ability to run at such lean levels of combustion. Of course, it is also possible to use EGR to augment NOX control if that is required, and other strategies such as water injection could also be used to control combustion temperatures.

The ability to control combustion over a wide range of air-fuel ratios gives some potential advantages over gasoline engines. In a diesel engine, the ability to control load by simply changing the air-fuel ratio through injection volumes means that the engine can run unthrottled and therefore more efficiently. If combustion of hydrogen can be controlled over very wide air-fuel ratios, then there is the possibility to run over a wide part of the engine range at wide-open throttle conditions.

As has been shown through experiment, the ability to run gasoline engines significantly lean also brings fundamental improvements in engine efficiency. Much of the work being done on pre-chamber ignition systems (both active and passive types) for gasoline and gas engines has, as a primary aim, the extension of the lean limit of combustion. The lean combustion limit is generally defined by an undesirable coefficient of variation effectively based on a certain level of unsuccessful combustion cycles. With the ability to burn successfully at much leaner mixtures, hydrogen not only promises extremely low NOX, but also greater efficiency.

Looking to the future

The road to net zero carbon emissions from transportation is being navigated very quickly, supported by public opinion and encouraged by legislation. Some governments have chosen to ban combustion engines while others have not been so proscriptive. Telling companies that they must not supply vehicles with IC engines is clear guidance and allows business planning, but it might not be the best solution in the longer term.

We have severe under-capacity in renewables, so it is hard to justify using such power to produce hydrogen for transportation when it can be used more efficiently in a battery EV. However, under-capacity in renewables doesn’t get us to net zero, and severe over-capacity is unaffordable if we are simply going to turn off those redundant wind and solar farms. There will come a point when we have to store large quantities of energy, and hydrogen is a very simple way to do this, with a wide range of applications for transportation applications of many varieties, not least passenger cars, buses and freight vehicles.

References

1) Oikawa M, Mogi Y, Horiguchi M, Goma K, Takagi Y and Mihara Y, Effect of modified combustion chamber configuration and enhanced squish flow on improving thermal efficiency in jet-plume-controlled direct-injection near-zero emission hydrogen engines, International Journal of Engine Research, IMechE (2022)

2) Liu Z, Guo Z, Rao X, Xu Y, Sheng C and Yuan C, A comprehensive review on the material performance affected by gaseous alternative fuels in internal combustion engines. Engineering Failure Analysis (139) (2022)

3) Hoffman K, Winsche W, Wiswall R, Reilly J, Sheehan T and Waide C, Metal Hydrides as a Source of Fuel for Vehicular Propulsion, SAE Paper 690232 (1969)