With a focus on enhanced combustion and aftertreatment control, Continental’s latest advances in emissions control attempt to negate factors such as temperature, acceleration style, route topography and fuel composition.

The main challenge for auto makers now is that the effectiveness of emissions reduction measures is influenced by a wide range of different factors. These include temperature, acceleration style, route topography and fuel composition, all of which have a huge impact on exhaust gas composition.

To ensure seamless emissions robustness in all operating situations, strategies must be found to compensate for these different variables. Two main trends can be seen. The first is that in many cases the same strategies can be used in both diesel and gasoline engines. This means a particulate filter and filter regeneration system may now be required not only for diesel engines but for gasoline engines too. For gasoline applications Continental has developed a solution that offers low filter back pressure. The second trend is toward leveraging the potential of powertrain hybridization to deliver further improvements in emissions performance.

“Our goal is to ensure robust performance in all situations,” said José Avila, member of the executive board of Continental and head of the Powertrain Division. “This is why our flexible system strategies cover the full spectrum – from engine optimization to sensor systems and exhaust aftertreatment. This is the only way to ensure that vehicles comply with emissions limits under all real-world driving conditions. This is what we mean by seamless emissions robustness.”

Ensuring seamless emissions compliance means catering for all potential operating conditions, from cold starts to full load. “For example, it makes a huge difference to engine-out emissions whether drivers are heading uphill or downhill at the start of their journey,” said Rolf Brück, head of the catalysts and filters product line. “Differences like these – between a low-load start or a high-load uphill start – can be compensated with the help of an electrically heated catalyst. This ensures that emissions control begins promptly regardless of wide variations in exhaust gas composition.”

In addition to the individual driver and route, factors whose impact on emissions is easily underestimated also include fuel quality. “Our tests have shown that in Western Europe alone, variations in gasoline fuel quality can affect engine-out particulate emissions by a factor of up to three,” Brück noted.

The overall system comprising engine and exhaust aftertreatment must be specifically designed to cater for such variations. In the future, emissions performance will also be affected by use of synthetic carbon-neutral additives such as OMEs (oxymethylene ethers) in diesel fuels. “This makes fuel composition sensing an increasingly important precondition for seamless emissions robustness – which is something we’re working on.”

As Continental’s diesel engine rig tests demonstrate, it is possible to harness the electrical power of a 48V hybrid powertrain to manage differences in temperature and speed profiles. Using electrical power to avoid torque peaks in the internal combustion engine reduces both fuel consumption and NOx emissions. Both parameters can be optimized by electrification of the drivetrain.

“Only by focusing on the complete picture – from the engine and the exhaust aftertreatment system, including sensors and their placement, to the development methodologies themselves – it is possible to develop a vehicle that is emissions-robust in all situations,” said Brück.

“New development tools hold the key to early-stage testing based on Real Driving Emissions cycles – which is the only way to design the overall system to cover all contingencies right from the start.”

Turning to gasoline engines, one way Continental has helped to lower engine-out emissions is with its XL5 injector, which reduces manifold-wall fuel condensation during cold-start. Nevertheless, even engines with highly efficient combustion processes still produce particulate emissions, which is why more and more gasoline-engined vehicles now feature a gasoline particulate filter (GPF).

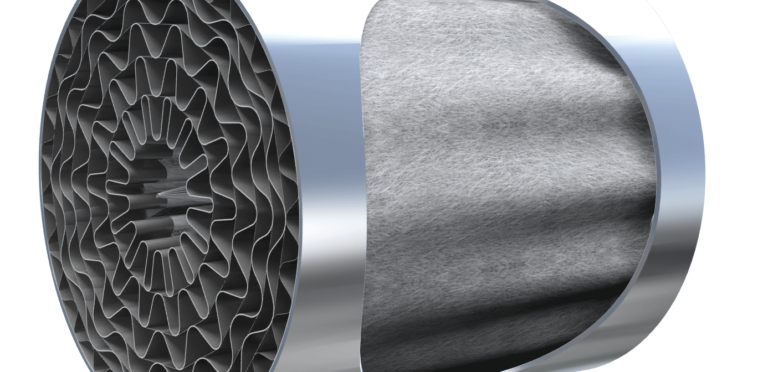

When the particulate load in the GPF exceeds a given level, the filter must be regenerated. Continental has improved filter regeneration in two ways. Firstly, the Continental GPF offers higher filtration efficiency despite its low back pressure, with the ability to outperform the particle size threshold of 23nm defined by current legislation.

Secondly, thanks to smart connectivity, the evaporated fuel which is collected in the tank in order to minimize hydrocarbon (HC) evaporation emissions can also be used for GPF regeneration.

“This is achieved with the help of our Active Purge Pump (APP), which frequently flushes the active carbon filter in hybrid applications as well, and simultaneously determines the HC content of the purged air. The quantity of fuel injected can then be rapidly reduced while still maintaining correct lambda control,” said Dr Gerd Rösel, head of systems development in Continental’s Engine Systems business unit.