UK company Swindon Powertrain has developed an 80kW crate powertrain, making it easier for specialist OEMs to electrify low-volume vehicles. Funded by the Niche Vehicle Network and working in partnership with iNetic and Code, Swindon Powertrain’s High Power Density project will create a turnkey crate transverse system with a high power/volume ratio.

“To date, niche manufacturers have not had access to compact, high-power EV powertrains they could source in low to mid volume, leading to a vacuum of supply,” said Raphaël Caillé, managing director, Swindon Powertrain. “When you factor in development costs, specialist OEMs haven’t been able to electrify their vehicles as quickly as they would like. Our crate powertrain will accelerate EV adoption in sectors poorly served by the larger Tier 1 manufacturers and integrators.”

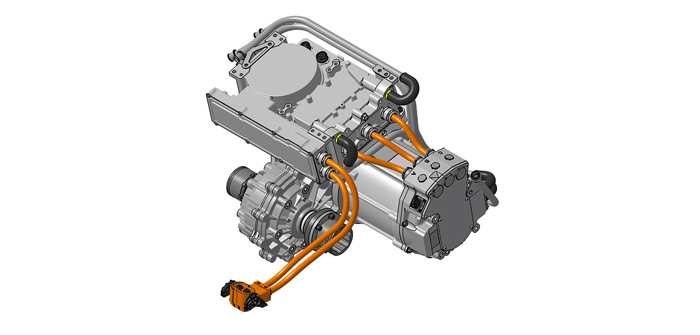

Designed to be compact, the HPD system is 600mm (24in) wide, 440mm (17in) deep and 280mm (11in) tall, while weighing in at 70kg (154 lb). This means that the motor, inverter, single-speed transmission and cooling system assembly can fit under the bonnet of a classic Mini, in a quad bike, or under the loading platform of a light commercial vehicle.

The HPD project will develop tooling, including castings, and identify manufacturing techniques to have the unit in production by June 2020. Core R&D and validation will be covered by the program, easing development costs further for integrators.

“Some of these classic EVs currently use second-hand parts of unknown provenance,” added Caillé. “The HPD project draws on our engineering expertise from over 48 years in motorsport to offer a reliable, compact and durable solution for this sector too.”

This project follows Swindon Powertrain’s program earlier this year to electrify an original Mini.