As the automotive industry undergoes arguably its biggest ever step change, Ben Gale, technical sales engineer, Horiba MIRA, discusses the pursuit of efficiency.

The automotive industry is going through one of its biggest transitions as the evolution from internal combustion engines (ICE) to electric vehicles (EV) enters a new age. As social and political pressures gradually increase, the need for an all-electric range (AER) automotive industry grows, painting an ever-popular picture of the future of automotive.

The current state-of-play involves OEMs and their desire to increase the energy available within EVs; this results in the need for increased battery capacity and energy optimization. In order to achieve this, OEMs rely heavily on cell chemistry improvements to aid the energy density or power density of their battery packs. Another option to gain energy is to look at how efficiently the system or vehicle operates. Horiba MIRA’s efforts will be to focus on this newer approach by offering OEMs Total Energy Management (TEM) analysis and development.

As the cell chemistry becomes more energy dense, the requirements for greater levels of safety and state-of-the-art cooling systems grow. Furthermore, long-term issues such as material sustainability, packaging and recyclability must take center stage as the industry manages the transition from ICE to hybrid and EV.

Improving the public perception and validity of EVs on our roads relies heavily on the new development in cell technologies and our ability to extract, use and reuse energy efficiently. Global automotive bodies and government officials are now identifying efficiency as a key attribute for new electric vehicles (NEV). For example, within the Chinese automotive sector lies the NEV point system, rewarding EVs on competitive statistics and the amount of distance traveled per kilowatt-hour on board.

Horiba MIRA has been working heavily with prototype EVs for nearly two decades and has led developments in new techniques, such as providing holistic TEM offerings to customers. This includes an internal, dedicated Energy Efficiency Group consisting of experts across the EV technical areas – electrical, software, thermal and mechanical.

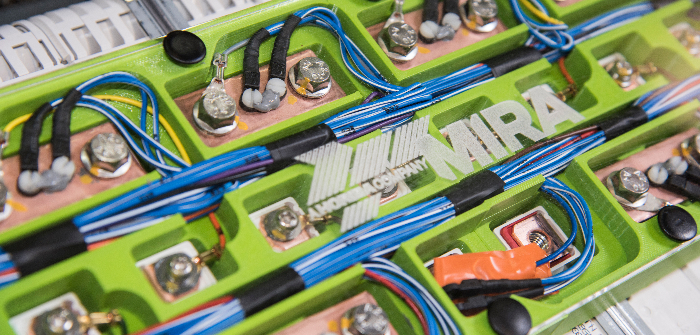

The emphasis on battery range presents many challenges, one of which is understanding the actual performance and characteristics of the battery cells. Horiba MIRA’s new Advanced Battery Development Suite (ABDS) enables us to carry out such activities at extremely high resolution and accuracy. With the ability to characterize cell performance, the technical boundaries continue to be pushed and result in more usable energy and consequently EV range. Horiba MIRA is also using the ABDS facility to investigate the details of cell aging mechanisms and how to keep cells within the ‘sweet spot’ – to lower the degradation and increase the durability of these cells.

The ABDS facility gives us the capacity to exercise modules and packs with up to 1,000V, 1,200A and charge at 600kW. These capabilities enable us to future-proof the facility for the next five years and verify pack performance and the design of future EVs. As we look at increasing performance and range, other components of a battery, most noticeably battery cooling, must be developed to ensure that everything runs at the most efficient level. Horiba MIRA’s ABDS facility, climatic wind tunnels and thermal testing equipment provide detailed analysis of battery, powertrain and cabin cooling to ensure maximum gains are made by its customers.

There are also other challenges we face when we look at range – driving style, traffic and additional weight produce both positive and negative outputs on battery life. Ambient conditions also play a large part in the EV world. From the beginning of EVs it was soon established that cold weather would play a significant role in the reduction of range. Therefore, we are now seeing more focus for OEMs to increase the AER at the temperature extremes (both hot and cold).

As OEMs look to deliver EVs with increased performance and software capability, the traditional engineering and attributes seem to fall by the wayside. Traditionally, OEMs would develop the vehicles based on knowledge from previous platforms and their test data legacy. Development programs would typically contain the refinement of traditional attributes such as dynamics, NVH and durability.

However, an abundance of new entrants and a lack of OEM legacy data has resulted in a shift of focus toward using software and simulation for increased performance. This may leave devastating holes within the vehicle development cycle as traditional engineering was, and still is, required. Horiba MIRA is supporting its customers with both traditional and non-traditional engineering techniques, strengthening the idea of a holistic approach.

With energy efficiency at the forefront of the automotive industry, OEMs continue to search for new ways to quantify energy usage. Previous schemes were based on the range of a vehicle, and lacked incentive to use their energy wisely. Schemes such as the NEV point system incorporate the measurement of TEM and give OEMs a strong focus on improving the overall energy efficiency in order to gain large incentives and remain competitive.