As Mazda works toward its Sustainable Zoom-Zoom 2030 development targets, the Japanese OEM has designed its first controlled compression ignition unit. Powered by gasoline, the SkyActiv-X SPCCI engine promises improved power, acceleration and environmental performance.

One of the principle points of focus in Mazda’s long-term technology development strategy, Sustainable Zoom-Zoom 2030, is the need to significantly lower CO2 emissions while offering cars that are both great to drive and reduce running costs through improved fuel consumption. As part of this movement, Mazda has committed to reducing its corporate average well-to-wheel CO2 emissions to 50% of 2010 levels by 2030, and by 90% by 2050.

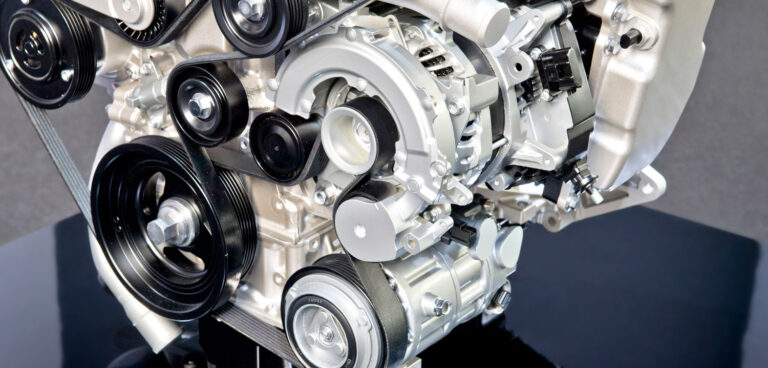

The SkyActiv-X SPCCI engine is claimed to offer outstanding power, acceleration and environmental performance by combining the attributes of both spark and compression ignition.

With two thirds of global electricity production currently relying on fossil fuels, the auto maker believes regulations placing the emissions of an EV at zero to be disingenuous. As when converted to a well-to-wheel figure, the average CO2 emissions of an EV can be close to a conventional vehicle depending on the energy mix the electricity is made from.

With the belief that electric powertrains do not currently satisfy society’s wish for a drastic reduction in greenhouse gas emissions, Mazda is focusing on bettering the real-world emissions of EVs by maximizing the efficiency of the internal combustion engine.

Accordingly, Mazda is looking to significantly reduce CO2 emissions from gasoline engines based on the analysis of combustion control factors. One of the key control factors is the use of a highly lean mixture of air and fuel: 2-3 times leaner than in today’s conventional engines. This mixture has so little fuel in the air that a normal engine with spark plugs cannot fire it.

Mazda already uses high compression ratios on its current SkyActiv gasoline engines to reduce fuel consumption, so this lead to the idea of increasing the compression ratio even further and igniting the fuel simply by compression as is the norm in modern diesel engines.

This approach has been subject of extensive research by various OEMs without development, the problem being the very small operating area in which a stable and predictable combustion was achievable.

With this in mind, Mazda developed its own proprietary combustion method, Spark Controlled Compression Ignition (SPCCI), and the company’s new 2.0-liter SkyActiv-X engine that uses this process.

With SPCCI, the engine injects a lean air-fuel mixture, compressing it up to 16:1 which is just below the level required to achieve compression ignition. To ignite the mixture at the right time, a small injection of atomized fuel directly around the spark plug builds a richer core.

When fired, this small core creates a pressure wave that runs through the combustion chamber, increasing the compression and temperature to the critical point where the main body of fuel combusts.

The power variation can be controlled via the aspired first charge and by a second charge injected shortly before the piston has reached its optimal position. This extends the area of lean operation and promotes very high fuel economy. Conventional combustion is used only at high engine loads and during very cold starts.

By controlling the compression ignition with a spark plug, issues of unstable combustion can be avoided, achieving a seamless transition between compression ignition and spark ignition. This means the engine can run more efficiently 80% of time.

In areas where low vehicle speeds are used frequently, fuel economy can be improved by 30% and CO2 emissions reduced by a corresponding amount thanks to the use of lean combustion.

With improvements most prominent in the light engine load range, Mazda believes the SkyActiv-X challenges the belief that medium gasoline engines have poor fuel economy in cities.