Transmission developers are applying all-new test and simulation techniques as electrification sweeps through the automotive industry

What are the main trends in transmission development currently? Where is the industry heading?

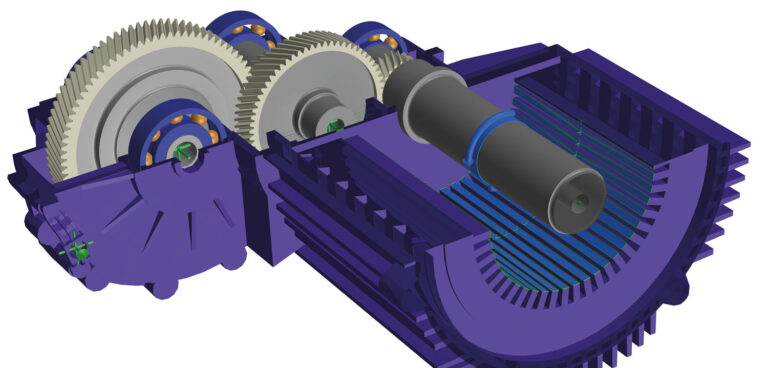

It goes without saying that electrification is the main theme. With EVs we are looking at higher speed of the electric machines with a greater degree of integration with the electric machine and the transmission. The two systems have to be engineered together from the very earliest stages, which is placing a strain on the organizational structure, processes and tools of conventional vehicle OEMs.

Many people are looking at 2 speed. In the past with ICE-driven vehicles we saw fewer ratios for smaller vehicles and more ratios for luxury cars and commercial vehicles, and this relationship will persist.

However, when applied to EVs this will mean single speed for the smaller and cheaper cars and two or more speeds will be for higher value vehicles and commercial vehicles. The precise boundary between the two domains remains to be seen as each OEM makes their own choice.

For HEVs, OEMs are looking to gain commonality between HEVs and the existing ICE-only-driven transmissions, which they need to maintain for the foreseeable future.

Looking further ahead, what do you see as the main transmission for 2030? Will any changes be required to the testing and development processes to make this a reality?

Looking further ahead, what do you see as the main transmission for 2030? Will any changes be required to the testing and development processes to make this a reality?

It is not possible to say with certainty what the market will look like in, say, 2030, only that we can suggest possible scenarios.

On the one hand, we have IEA predicting vehicle sales to be rising to 120 million per annum by 2030, on the other hand we have Tony Seba of Stanford University predicting car ownership to decline by 80% in the same period. Both respected sources, both having researched their subject, pointing in opposite directions.

Not only are these scenarios pointing in completely different directions, but they are both presented with such confidence and certainty that numerical values are proposed in terms of the number of vehicles and types of transmissions.

What I prefer to see is something much more nuanced. I agree with the long-term narrative that says that HEV will be an intermediate solution on the long-term route to EVs taking over, but whether peak-HEV will be before or after 2030 cannot be predicted for certain. I expect both to be significant players in 2030.

Is simulation/virtual testing playing an increased role in transmission development? Is there a move toward fewer physical prototypes?

Indeed. Thirty years ago the idea of concurrent engineering was introduced based on the economic benefits of having more simulation and fewer physical prototypes. Electrification provides an additional step change in that the old test procedures based on decades of experience in testing ICE-driven transmissions are no longer valid.

Furthermore, in some areas we see a convergence of the theoretical (simulation) and the practical (real-life performance) in the form of digital twin. In this case, it is possible for the simulation model to remain associated with a physical asset throughout its operational life, providing valuable information on its performance and remaining value.

Are timeframes getting shorter? Is it quicker and easier to develop an all-new transmission today, than it was, say, 15 years ago?

As well as the pressure to shorten time, there is the sheer number of different designs. If we combine the different chassis types, ICE/electric machine types, transmission types, driveshaft types and include the fact that there may be more than one supplier for a given sub-assembly, a manufacturer can end up with more than 100 variants of the same basic vehicle.

It is simply not possible to test all of these, and they struggle to simulate all the different options. Commercial pressures naturally lead to accelerated product development timescales.