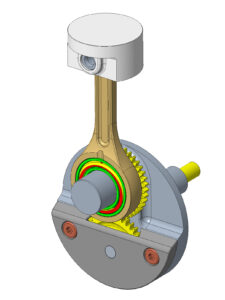

Dutch engineering company Gomecsys has been developing its variable compression ratio (VCR) technology for mass production of single-cylinder motorbike engines. The technology varies the compression ratio by adding an eccentric link between the crankpin and the conrod big end, making it possible to modify the compression ratio between 9.5 and 15:1, resulting in a fuel and CO2 reduction of 8-10% up to 5 bar BMEP.

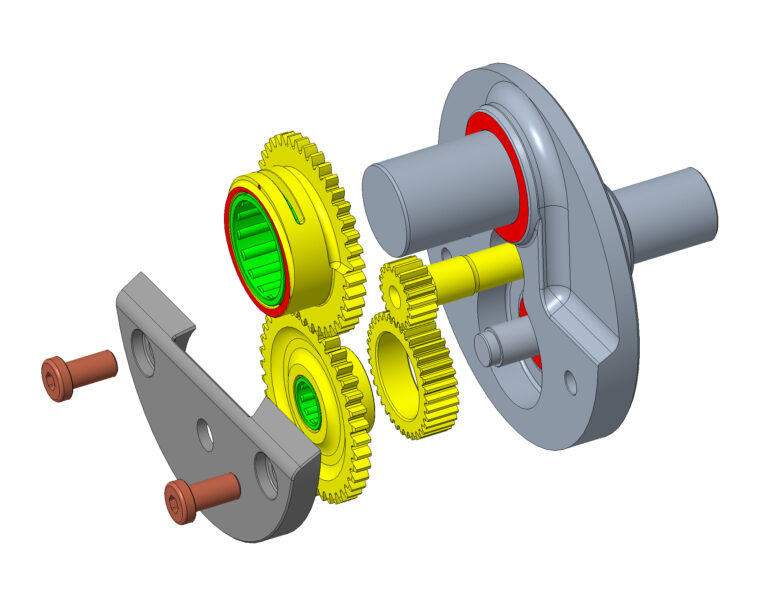

As these single-cylinder (125cc to 300cc) engines normally use an assembled crankshaft, the eccentric link can be placed between the crankpin and the conrod during assembly. The use of roller bearings helps to optimize the backlash of the gears, which is important for NVH. The patented gear drive system rotates the eccentric at half the speed of the crankshaft, which means that the roller bearings on the inside and outside of the eccentric both run at half the crankshaft speed. This is essential to keep the total engine friction levels low.

The integration of the VCR system into existing single-cylinder motorbike engines is achieved by replacing the normal crankshaft with a VCR crankshaft. In many cases, however, additional space is required in the crankcase for the VCR conrod big end, which has a larger diameter than the standard conrod.

Furthermore, the VCR actuation system needs to be integrated within one of the crankcase covers. The actuation shaft that runs through the inside of the crankshaft is in a stationary position with the crankshaft running around it and driving the VCR gears. The VCR shaft only rotates to modify the compression ratio, with a total rotation angle of 320° from maximum to minimum compression ratio. Gomecsys offers different solutions for the VCR actuation system, with an electric motor/worm drive system and several hydraulic solutions.

Another notable advantage of the VCR system is that because of the reduced knock sensitivity at higher speeds, an increased compression ratio can be used at full load (12:1 at 6,000rpm), which not only increases efficiency by 5-6% but also reduces the temperature of the exhaust gases by 50-60°C thanks to the increased expansion. In most cases this means there is no need for fuel enrichment to reduce the exhaust gas temperature.

The use of the higher expansion ratio of 12:1 also increases the torque of the engine by 5-6%, around the same level as seen from fuel enrichment. For engines normally running lambda 0.85 at full load, running with increased expansion ratios at higher speeds shows up to 20% fuel and CO2 reduction without power loss.

The combustion load on the VCR gears can easily be kept within reliable bounds, which is around 5Nm for the actuation shaft, by reducing the compression ratio if needed. This is because at the lowest compression ratio position the eccentric link is in line with the conrod during peak firing pressures. The gear load is at minimum levels while running full load at lower speeds. At higher speeds the mass forces reduce the effect of the combustion load on the gears and the compression ratio can be increased during full load.

Gomecsys has developed its own R&D engine for single-cylinder motorbike applications and offers it to OEMs for faster prototype testing of their own engines. The engine can be equipped with the OEM’s cylinder block and cylinder head and tested with a normal crankshaft with fixed compression ratio and a VCR crankshaft.

One of the main advantages of the R&D engine is that the engine is tested without the gearbox, clutch, balance shaft, etc, allowing direct assessment of potential engine efficiency benefits. An electrically driven oil pump outside the engine is used to provide the oil supply and oil pressure to different points of the engine and can be regulated separately.

The latest development of the VCR system involves the balancing of the eccentric to cancel out the forces between it and the conrod big end working on the eccentric gear. With this improvement, Gomecsys’s engineers say they have reduced the load on the VCR gears from mass forces by more than 50%.

Gomecsys is currently working closely with several motorbike OEMs to bring this VCR technology to mass production.