The reality is starting to set in that electrification is not the silver bullet for the world’s emissions challenges. When you consider the true carbon footprint of an electric vehicle’s entire lifecycle along with the necessary upheaval in the grid infrastructure, electrification alone is not a sustainable solution to meet global transportation needs. “We absolutely need battery-electric vehicles and they will make a massive difference but we need more of them and as fast as possible,” says Steve Sapsford, managing director at SCE (Southern California Edison), a renewable energy specialist.

He goes on to note, “The average vehicle life in Europe is around 11 years. Currently, we’re simply not renewing that fleet fast enough with electric vehicles. Therefore, we cannot rely on EVs alone to reduce our transport CO2 emissions. We need to stop debating about which is the better propulsion system because we need all of them to make a difference right now.”

An alternative that recently caught the attention of motorsport and the wider automotive industry is drop-in sustainable fuel. By replacing gasoline and diesel derived from fossil fuels, sustainable fuels utilize existing combustion engine technology and an infrastructure that has been optimized for liquid fuels over the last 160 years. But what makes a fuel sustainable and what are the differences between biofuels, advanced biofuels, synthetic fuels and the latest buzzword, e-fuels? A true sustainable fuel is one that does not add any additional carbon to the atmosphere. It is produced using recycled carbon, sourced from either biomass or directly out of the atmosphere.

When it is burned, the amount of CO2 it releases equates to the amount of CO2 that was originally absorbed by the plants from which it was derived through photosynthesis, or from industrial-scale direct air capture, in effect recycling the CO2. However, due to the variety of different feedstocks used, the processes involved and the sources of electricity powering those processes, there is some debate over which fuels are truly sustainable.

The most common sustainable fuels in use today are traditional biofuels. These include bioethanol and biodiesel, which are currently blended with fossil fuels to create, for example, E5 petrol, which consists of up to 5% bioethanol and B7 diesel. Biofuels can be classed as either first generation, where they are formed directly from food crops, or second generation, where they are produced from agricultural biowaste.

“First-generation biofuels are probably considered to be a necessary evil at the moment but they are not sustainable,” explains David Richardson, business development director at fuel developer Coryton. “To use more biofuels, we’ll need to compete with land for food crops, which we’re already seeing short supplies of. What we want to do is replace that first-generation biofuel with a second-generation biofuel. In other words, instead of using the crop, we’re going to use the waste from that crop, so we’re not competing with anything.”

Second-generation biofuels still only use the CO2 already in the atmosphere, which has been absorbed in the growing phase of the crop. Lignocellulosic biomass such as forestry waste, agricultural residues and straw is first pretreated and then goes through an enzymatic hydrolysis process that converts enzymes into sugars. A variety of microorganisms then ferment these sugars into ethanol. This bioethanol can be added to fossil fuel-based gasoline as a blend to create fuels such as E5 (5% bio content) and E10 (10% bio content). Unfortunately, only a small amount of pure bioethanol and biodiesel can be used in most vehicles because the ethanol content can cause problems with fuel systems and provides poor performance in engines running at lower temperatures.

Fortunately, bioethanol can be converted into biogasoline to create advanced biofuels to replace fossil fuel-based gasoline. This results in a 100% sustainable fuel (bioethanol + biogasoline) that has no engine compatibility issues and is therefore a true drop-in. These are the sorts of fuels that the WRC and, soon, Formula 1, are turning to.

“To use more second-generation biofuels, we have to take another step forward,” says Richardson. “We know we can’t use all the components in their current guise because technically they don’t perform in legacy engines or fueling systems. We need to utilize biowaste and do a bit more work to create a fuel that is a true drop-in and looks and behaves like a normal fossil fuel hydrocarbon. We need to convert second-generation biofuels into advanced biogasolines and diesels.”

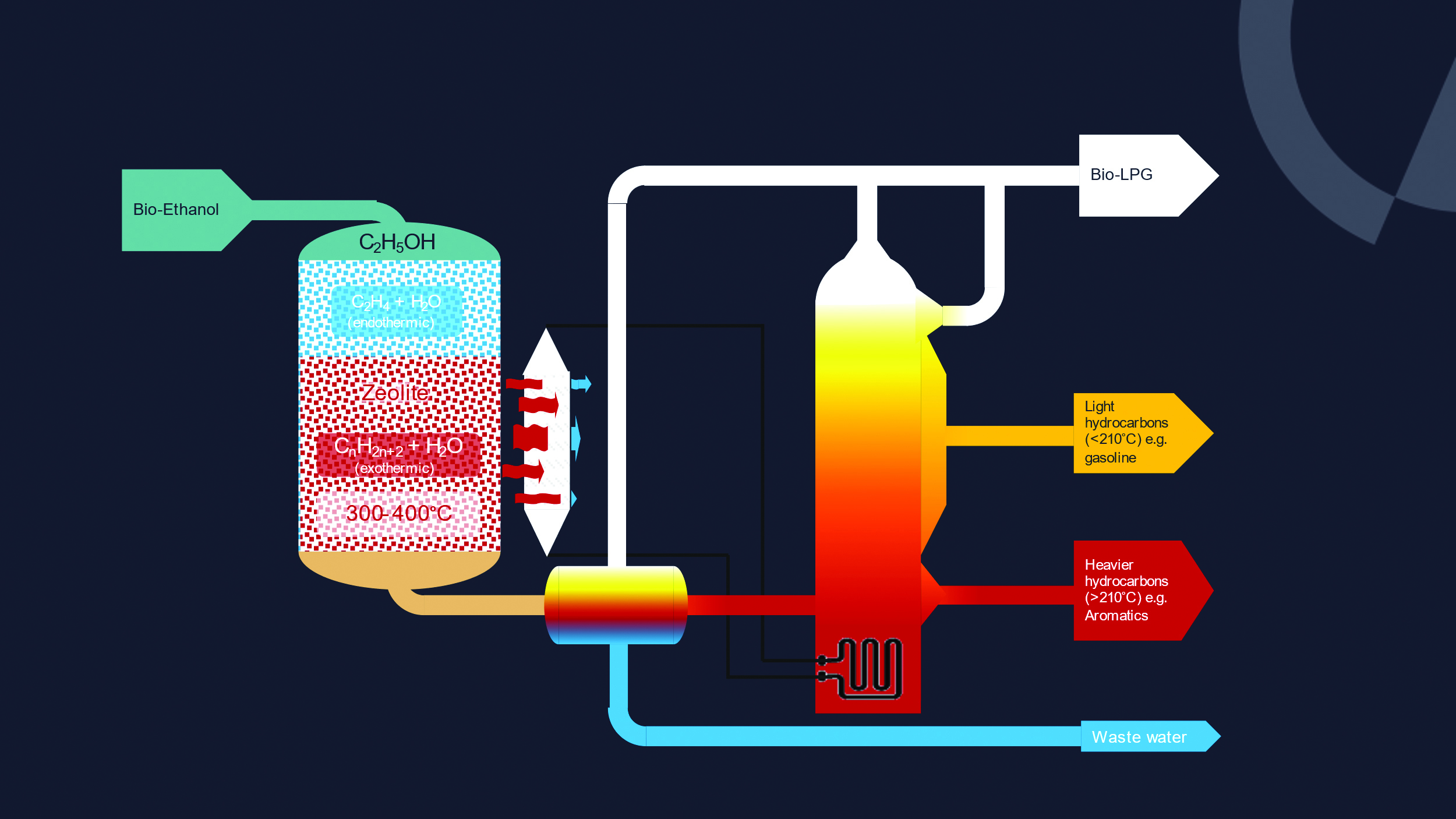

To achieve this, bioethanol is first dehydrated down to ethylene and then ‘grown’ into longer-chain hydrocarbons using a zeolite catalyst at 300-400°C. This process removes the oxygen molecules and creates a mixture of hydrocarbons that is then fed into a distillation column. Here, the constituents with the lowest boiling points are extracted from the top and those with the highest boiling points exit at the bottom. The lighter ‘cuts’ from this process are used to produce gasoline, while the heavier cuts, such as aromatic hydrocarbons, can be used in other industries including agriculture, chemicals and pharmaceuticals. “What we’ve effectively done is use existing infrastructure and processes to produce a gasoline but we’ve only used biowaste feedstocks,” summarizes Richardson.

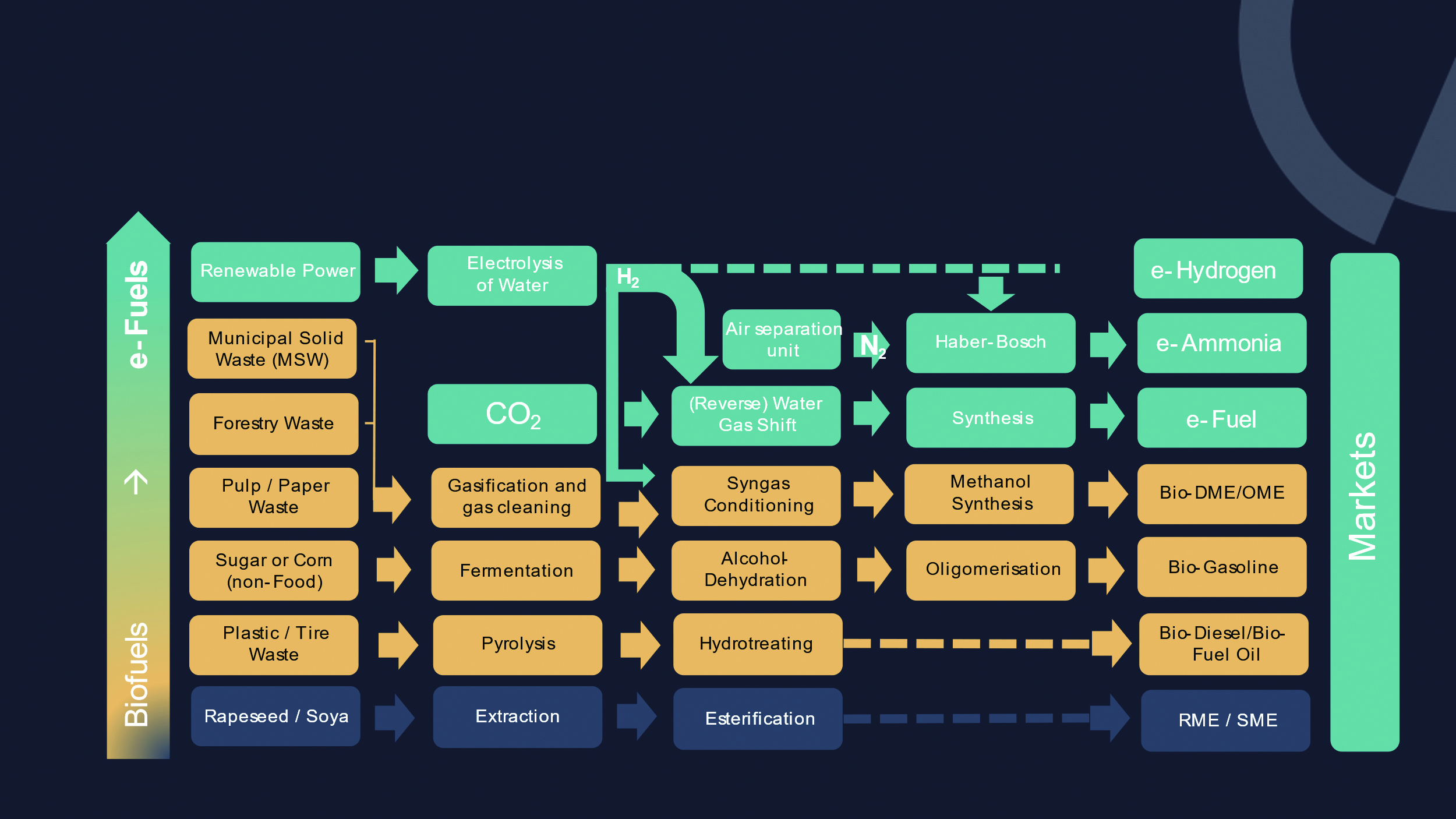

There is another way to create sustainable fuel, which involves combining hydrogen with CO2 in a reverse water gas shift process. This forms a syngas that then goes through a Fischer-Tropsch-like process to form liquid hydrocarbons. However, variations in the production process mean these synthetic fuels are often not truly sustainable. The CO2 can come from a variety of sources such as biomass or direct air capture, but the hydrogen is typically derived from fossil-fueled processes.

However, if renewable energy can be used instead to create hydrogen through means such as electrolysis, the result is a fully sustainable e-fuel also known as a power-to-liquid fuel. “E-fuels rely entirely on having access to off-the-grid renewable electricity and that’s the problem,” says Richardson. “I’d argue that there are currently no facilities in the world capable of producing the volumes we need to go to mass market. Pilot plants are out there and producing up to 40,000 liters a year but that’s a drop in the ocean.”

The biggest challenge facing the industry today is the current lack of incentive to invest in developing e-fuels and the necessary infrastructure, because they are more expensive than fossil fuels. Consequently, the industry is at least 5-10 years away from having any meaningful e-fuels entering the market and over 30 years from a point where they could replace fossil fuel-based fuels completely. The short-term solution for motorsport is therefore to focus on advanced biofuels. These fully sustainable bio alternatives can be used in most current internal combustion engines and achieve greenhouse gas savings in excess of 80% compared with fossil fuel equivalents (as per the fossil fuel comparator figure of 94g CO2eq/MJ which is defined in the European Renewable Energy Directive).

“Today we can tackle captive fleets with advanced biofuels, and this is where motorsport is going to be a huge driver in the uptake of sustainable fuel technology,” explains Sapsford. “Most race series use between half a million and a million liters of fuel per season, which is in the sweet spot of the available quantities of advanced biofuels. This means that existing race series can reduce their greenhouse gases by around 80% by simply switching over to advanced biofuels.”

To evaluate the performance of advanced biofuels against fossil fuels, Coryton partnered with M-Sport and Cosworth to conduct a variety of engine tests. Second-generation advanced biogasoline was tested in a current 1.6-liter turbocharged WRC engine, a 2.3-liter Ford Ecoboost turbocharged engine and a high-speed 1.0-liter naturally aspirated Cosworth engine. There were some subtle performance differences between the fuels, which could be explained by the relative octane quality. Otherwise, there was no fundamental difference in engine operation, the result being that these fuels were proved to be suitable as a direct replacement for fossil fuel-derived fuels in ICEs without the need for recalibration.

Formula 1 is the most visible series to have begun the adoption of sustainable fuels by regulating that 5.75% of current fuel needs to come from a bio source, although it has not specified that these have to be second-generation fuels. Teams are already looking for loopholes within the fuel regulations, which does not necessarily support the sustainability intent of the rules.

“Formula 1 works on a fuel flow formula using a maximum flow rate of 100kg/h, so the requirement [of teams] is to use this allowance [5.75% bio content] to add the highest possible energy content,” explains Pat Symonds, chief technical officer at F1. “Consequently, everyone is using a synthetic [first-generation] iso octane, which comes from a single source and is doing very little to advance the science. So for 2022 we’re making a change and going to replace the first-generation iso octane with 10% sustainable bioethanol. This is really a holding position until we move forward with a real, challenging and relevant target.”

With a new powertrain set for introduction in 2025, F1 is currently exploring the potential opportunities of new regulations. Currently, F1 cars use 110kg of fuel with a lower heating value (LHV) of around 43MJ/kg. That equates to approximately 4.73GJ of energy or 1,300kWh per race. F1 is also considering dropping this to 800kWh and reducing the maximum fuel flow rate so that around 400kWh comes from the engine, with 400kWh supplied by the electrical systems. “Our target is to be net zero carbon as a sport by 2030. We think the hybrid engine combined with advanced sustainable fuels has an important role in decarbonizing the global transport sector,” notes Symonds. “We must remember that over 1.1 billion vehicles are powered by ICEs. We believe the solution to the ongoing environmental situation regarding mobility is going to be many parallel paths, not just one.”

A host of other series are also looking to adopt biofuels. For example, the World Rally Championship (WRC) is set to run on 100% sustainable fuel from 2022 onward. It is becoming increasingly clear that the only way to reduce the carbon footprint of the transport sector is by pursing a variety of solutions. Some technologies will make a difference in 20 years’ time but others can make a difference today. Motorsport has a role to play pushing development.

“It would be daft to say that electrification hasn’t got a role to play – it absolutely has,” asserts Richardson. “But for the last 160 years we’ve developed an infrastructure that is highly optimized for dealing with liquids. Instead of getting rid of this entirely and switching to electric, let’s continue to utilize it but use fuels that are generated from carbon already present in the atmosphere.“