Maserati’s return to the super-sportscar segment will be a showcase of what its newly expanded facilities in Modena can deliver. Launching in 2021, the MC20 is a scratch-built modern halo car. It’s designed for racing, built for an electric powertrain and is the first application of the company’s new V6 gasoline engine – every element of which was developed in-house.

Requirements for the Nettuno engine were laid out in 2018, according to the project’s chief engineer Matteo Valentini. It’s the car maker’s first in-house engine program in 20 years, delivered through close collaboration between its Innovation Lab in Modena and newly established Engine Hub nearby. The latter offers bespoke dynos, workshops and assembly areas, which enabled design, virtual analysis and prototyping to be carried out under one roof, supported by suppliers.

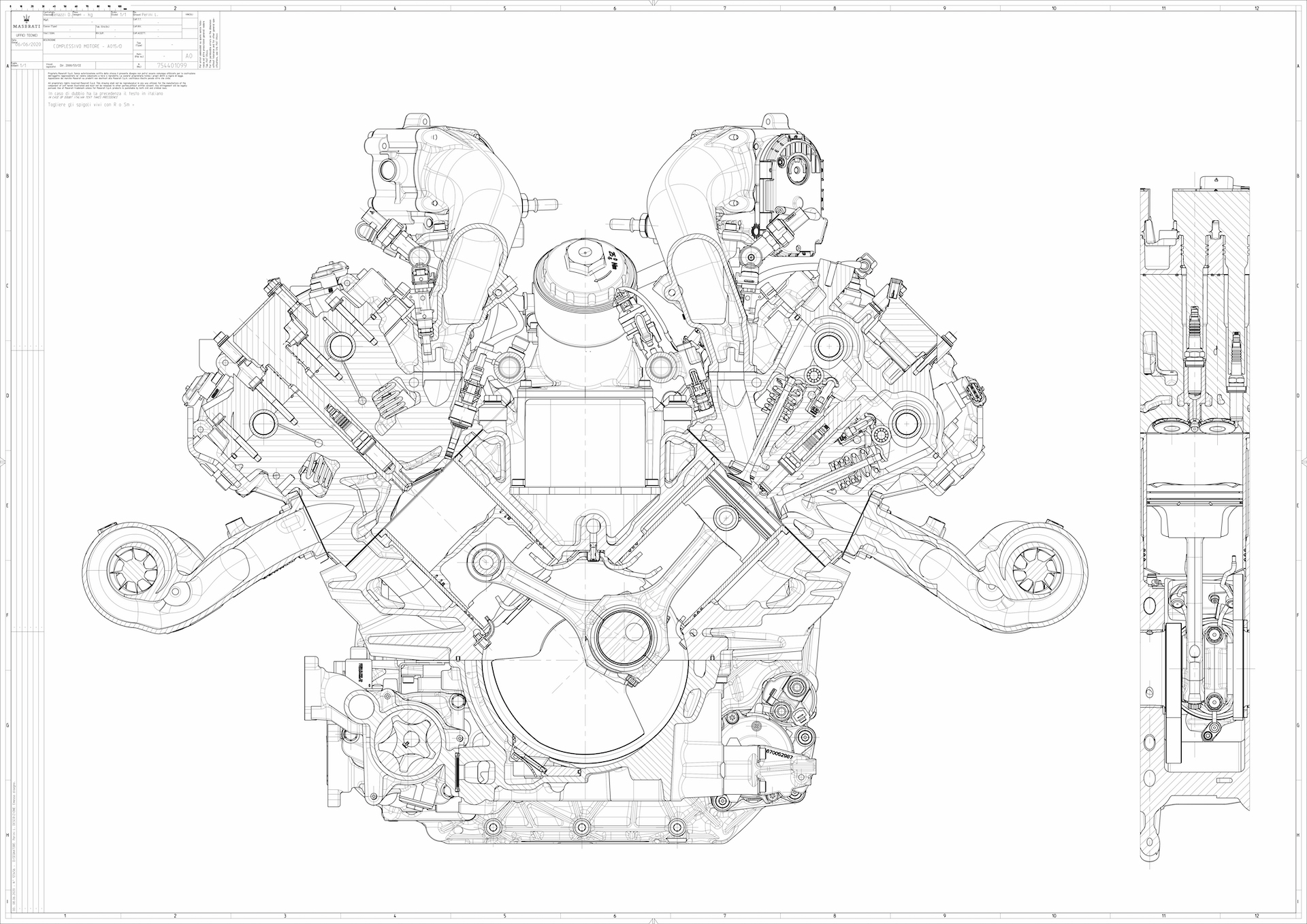

The MC20 presented a challenging first application: a mid-mounted layout in a monocoque also designed for electric drive, and with a low, aerodynamic roofline further constraining the available space. Valentini says this focused development on a compact six-cylinder architecture also required a dry sump system, which reduces the height of the engine by 100-150mm and enables it to be mounted lower in the chassis without compromising ground clearance.

“We had to do a lot of work in terms of the architecture of the engine because we have to fit a very compact package,” he says. “We analyzed a lot of different solutions but the V6 90° architecture is the best solution to achieve the lowest center of gravity and it met all the packaging constraints and the [targeted] power to weight ratio.”

Maserati had already begun development of a pre-chamber combustion system in 2015, and the Nettuno is claimed to be the first to bring this F1-derived technology to market. Fuel is injected directly into the cylinder at 350 bar, and the air/fuel mixture is pushed into a central pre-combustion chamber during the compression stroke. Near top dead-center, the mixture is ignited by a spark plug in the pre-chamber then channeled back into the cylinder via a series of holes, triggering multiple further ignition areas. The result is claimed to be a faster, more uniform combustion at high loads, resulting in improved fuel economy and performance.

Although the pre-chamber system was an important component for delivering the >200ps/liter target performance, Valentini says it presented some challenges for road use. “At low loads, the pre-chamber had some drawbacks in terms of combustion stability and noise, because the combustion process is faster. We solved this issue by adding the second spark plug and the [6 bar port] injection. This meant we were able to keep the advantages of the pre-chamber and meet the stability and the NVH requirements for a road vehicle.”

In the MC20, the new engine is equipped with twin side-mounted fixed-geometry turbochargers with electronically actuated wastegates. A bespoke design that’s focused on space efficiency, they feature a newly designed steel alloy capable of withstanding exhaust temperatures of more than 1,000°C. Although it’s not a requirement yet, this will enable future applications to meet forthcoming emissions targets, where over-richening of the mixture for cooling will not be possible.

With short turnaround times and new technology on board, simulation played an important role during development. Engineers combined tools available at the Engine Hub (right) to analyze the behavior of the pre-chamber system, but also to streamline the complicated process of packaging its components within the cylinder head. Detailed thermal and mechanical analysis early on was also vital for time-efficient design of under-load components. These were correlated with the first dyno tests once prototypes became available in early 2019.

“The power cell and the core components are modular,” Valentini explains. “If we want to adapt the combustion technology to other architectures, we are able to do so. The core of the engine is adaptable to other V6 configurations in the future. If the market or the company asks for hybridization, we will adapt the solution to the request.”

Concurrent development of an all-new chassis and powertrain meant the earliest on-road tests had to be carried out in custom-built mules – Maserati has no mid-engined products to use as a base. This process began in November 2019, before switching to the first camouflaged MC20 prototypes four months later, initially on the roads around Modena. Despite travel restrictions during the Covid-19 pandemic, hardware-in-the-loop testing has continued at the Innovation Lab, correlated with real-world testing as series production draws closer.

“We have increased the efficiency of the design team a lot using all these tools,” says Valentini. “We were able to achieve the target of performance without any critical failure or issue. Nettuno is a very compact, very light, very powerful engine, and we have a strong bond to the legacy of Maserati when it was producing its own engines in the past. We were true to our legacy, and we achieved the best performance we could have imagined with the new technology we implemented.”