Mazda has been building Wankel rotary engines for over half a century, producing more than 2,000,000 of them – far in excess of any rival OEM. Each time the automotive world proclaims the concept is dead, Mazda brings it back. The latest rotary revival comes a decade after the previous one, the Mazda RX-8, wailed its way to the engine gods in a cloud of blue exhaust smoke: say hello to the Mazda MX-30 R-EV.

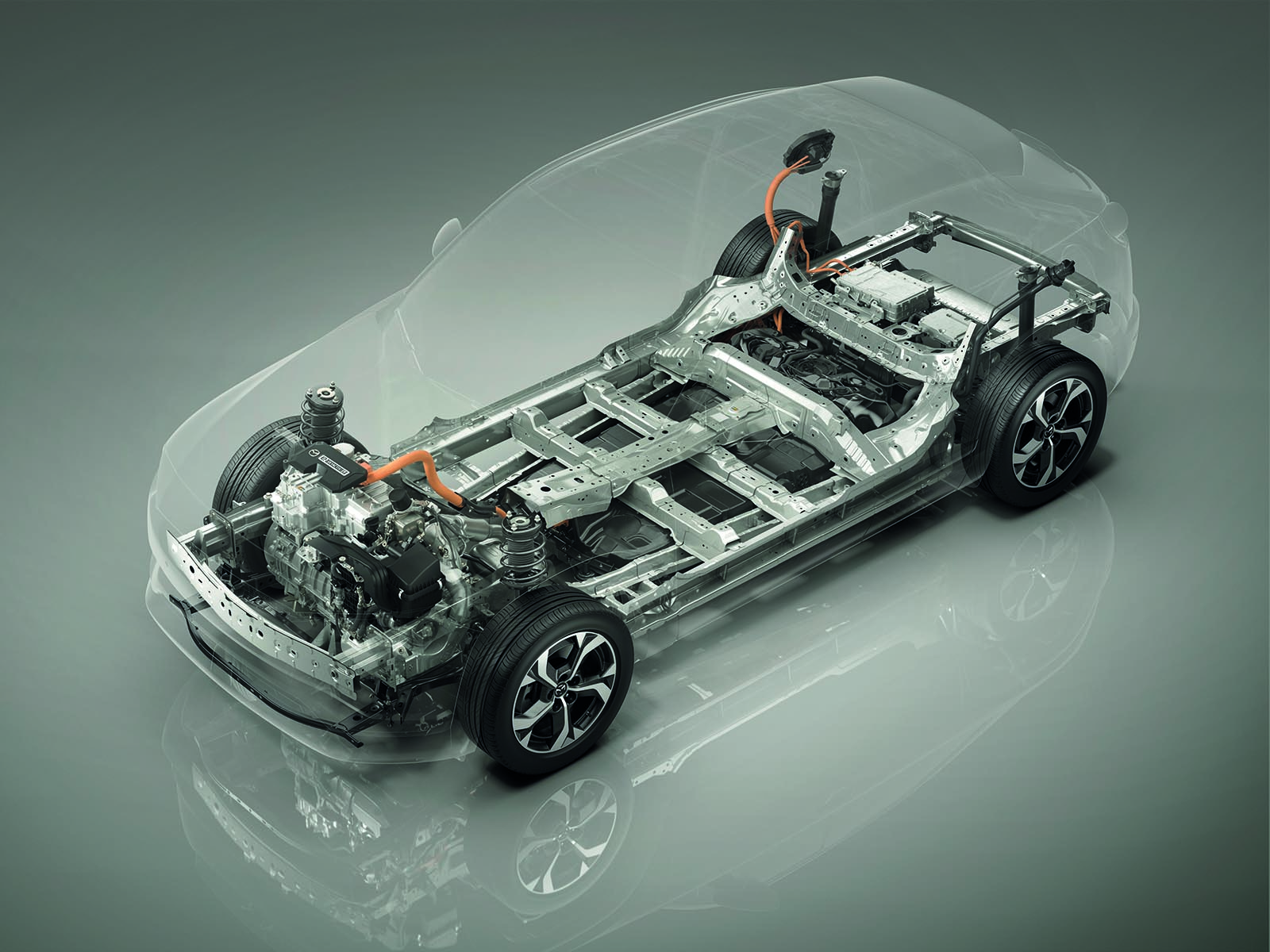

The regular MX-30, a compact crossover SUV, is a battery-electric vehicle. The new MX-30 R-EV is a series plug-in hybrid, with the rotary engine (christened 8C) serving as a power generator rather than directly driving the wheels (as it does in the parallel hybrids that dominate the marketplace).

The rotary engine’s days as a standalone ICE may well be over, but Mazda insists its new role here is not because of rose-tinted romanticism but simple engineering common sense. At the 2023 Brussels Motor Show where the new Mazda MX-30 R-EV made its world debut, we spoke to Mazda Cars program manager Wakako Uefuji and her team to find out more.

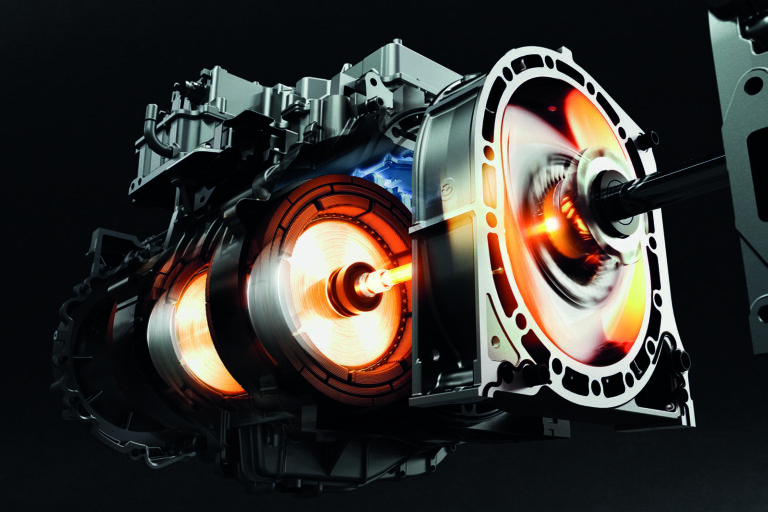

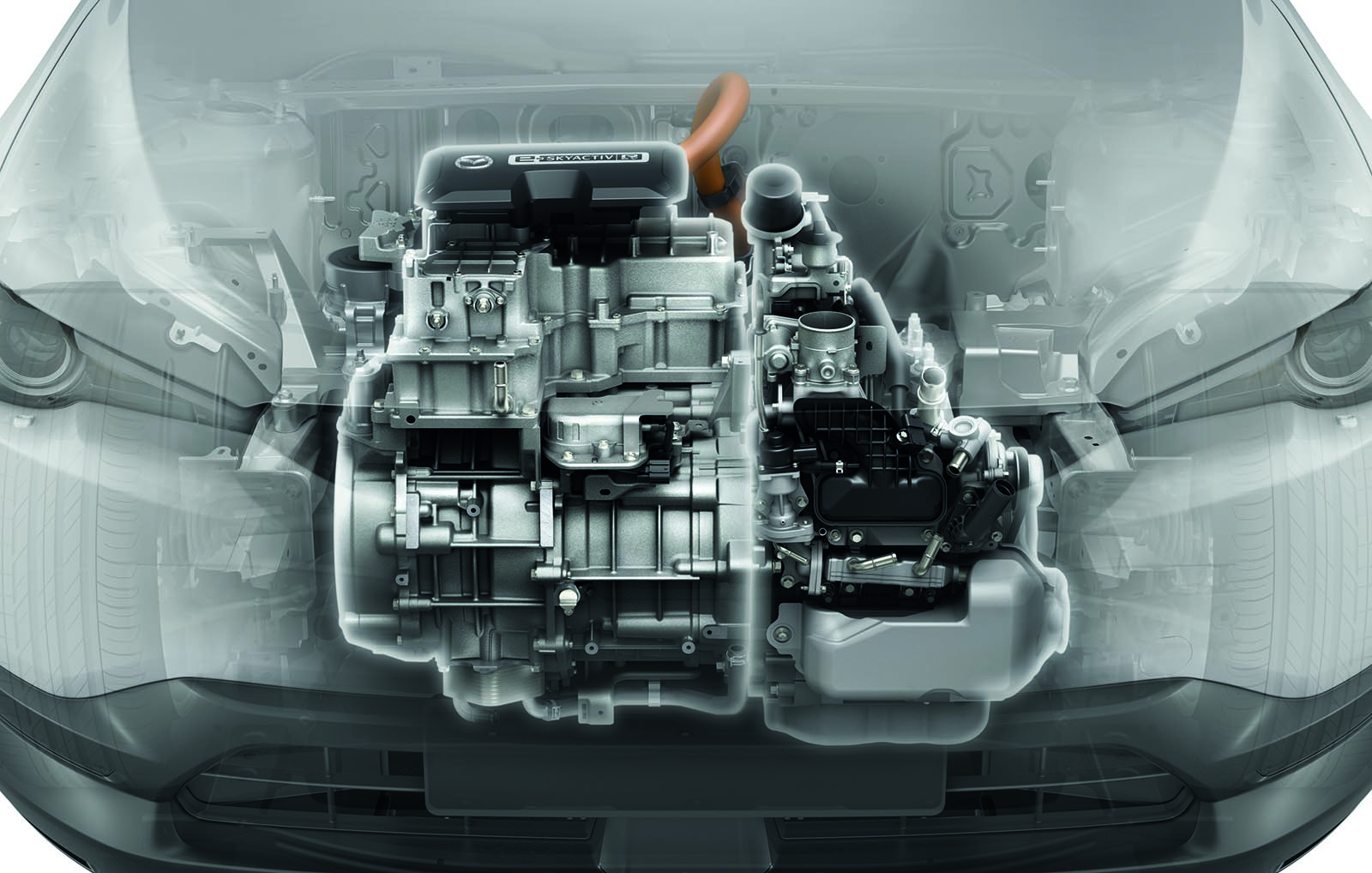

Simplicity was the prime driver. A rotary engine, she explained, is easy to combine with generators, batteries and fuel tanks. Here, it is located coaxially and fully integrated with the electric motor, decelerator and generator, creating a unit with an overall width of less than 840mm. It is so compact that the series hybrid rotary engine can be incorporated in the engine bay using the same body frame as the MX-30 BEV, currently the only model based on Mazda’s Skyactiv vehicle architecture. “The characteristic high engine speed of a rotary engine means it is very good for using in sports cars,” said Uefuji. “But its compactness means it’s also ideal to use as a generator; here, we are using size to our advantage, to optimize the total package.” Although mass production of rotary engines was discontinued in 2012 with the demise of the RX-8, Mazda continued research and development, to “never let its light go out”. The MX-30 R-EV is the result of that work.

Three challenges

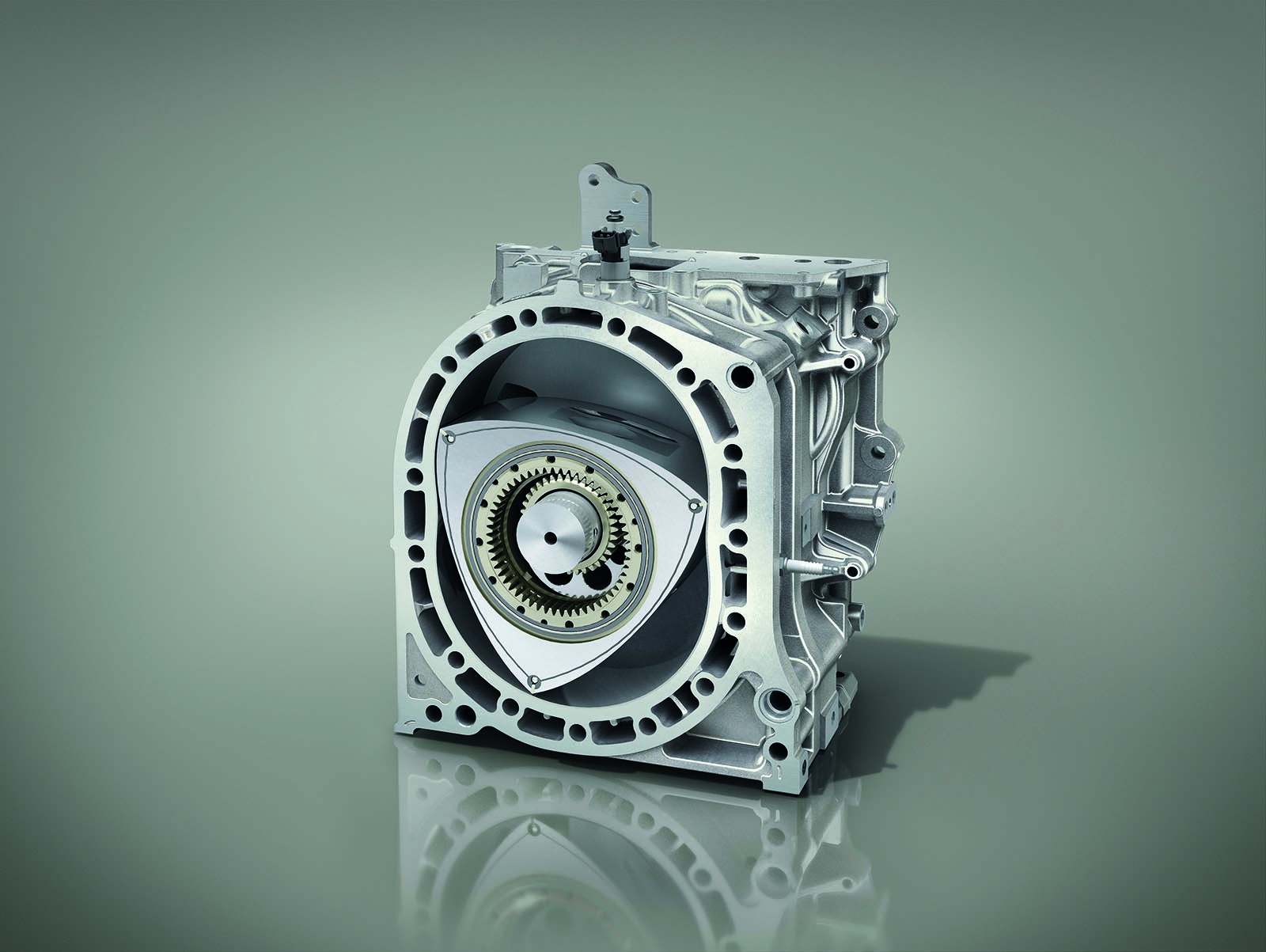

Mazda Cars technical expert Yoshiaki Noguchi told us there were three key challenges that had to be addressed if the rotary engine was to return: making it lighter, more fuel efficient and more reliable. The old Mazda RX-8 engine, known as Renesis, was a twin-rotor design, with dual 654cc chambers. The new 8C engine is an 830cc single-rotor format, with a 120mm generating radius of the trochoid curve and 76mm rotor housing width. There are two intake and exhaust ports on the side. Compared with the Mazda RX-8, the new MX-30 R-EV engine is more than 15kg lighter thanks to the use of aluminum for the side housing section of the structure; the Renesis engine used cast iron. The use of direct injection was pivotal to improving efficiency.

“The RX-8 was a port engine,” said Noguchi. “This is our first direct-injection rotary engine.” The engineers, he explained, had long ago identified direct injection as key to improving the efficiency of rotary engines. However, they weren’t able to implement it on the existing Renesis engine because an all-new design was needed in order to make the switch.

Rotary engine combustion temperatures constantly vary, explained Noguchi. “Achieving a homogeneous mixture is difficult. The combustion chamber is always rotating, yet the fuel wants to stay in place. It means the top half of the mixture is lean and the latter half is rich – it fails to fully combust and is expelled as unburned gas, impacting both fuel economy and overall engine output.”

Direct injection is the solution; it allows the air-fuel mixture to be more evenly distributed across the main combustion area, improving efficiency and reducing emissions. According to Noguchi, extensive computer simulation enabled engineers to precisely calculate the movement of the mixture inside the chamber and, through optimization of both fuel injection and injector angle, deliver up to a 25% improvement in fuel economy. What’s more, by atomizing the fuel at the time of injection, fuel is fully vaporized even at lower temperatures, preventing the risk of injecting excess fuel and reducing fuel consumption.

The rotary engine now has an exhaust gas recirculation (EGR) system. It operates mainly at low RPM and low loads, improving fuel economy by preventing cooling losses caused by the larger surface area of rotary engine combustion engine chambers than are present on a reciprocating engine.

Despite the use of EGR, one thing rotary engineers don’t have to worry about unduly are NOx emissions, added Noguchi. “They are naturally good on NOx emissions due to the lower combustion temperatures. It’s CO and HC that are more of an issue, so we focused our attention on cutting emissions of these.” The 8C engine runs a much higher compression ratio than older rotary engines, at 11.9:1. “This is very high, even by the standards of reciprocating engines; rotary engines typically run lower compression ratios.” This ratio was achieved by better sealing of the mixture through optimizing the apex seals.

Traditionally, explained Noguchi, improving the sealing of the gases was achieved mainly by increasing the pressure on the sidewall, which also had the result of increasing wear. “To overcome this, we have increased the width of the apex seals on the tip of each rotor from 2.0mm to 2.5mm, which improves wear resistance. We have also changed the plating on the trochoid surface, reducing wear and frictional resistance.”

As well as aiding efficiency, this is beneficial for reliability, said Noguchi. The sides of the housing are now surfaced in aluminum, with a high-velocity oxygen fuel coating that adds a ceramic surface, further reducing wear and frictional resistance. Excess oil consumption, he confidently insisted, will simply not be an issue with the new Mazda MX-30 R-EV engine.

Rotary reinvented as a generator

Because the rotary engine acts as a generator rather than a direct drive to the wheels, the Mazda engineers originally tried running it at a constant speed. “But once we started driving prototype versions, we changed this,” revealed Noguchi. “It didn’t give a ‘Mazda’ feeling. We decided to vary the engine speed, according to driver behavior.”

Engine speed is therefore constantly changing, although as it’s working as a generator, there’s no need to do this aggressively to deliver fast acceleration. “It varies as smoothly as possible, and the curve is more gentle, which also helps with reliability.” In contrast to the ‘howling’ rotary engines of old, maximum engine speed is 4,500rpm, with the lower end around 2,000rpm (“we don’t need to have a low engine idle speed”).

The rotary engine produces 75ps at 4,500rpm and 117Nm at 4,000rpm. The electric motor, meanwhile, produces 170ps at 9,000rpm and 260Nm at 4,481rpm; it has an oil-cooled motor body, helping to make the drive unit more compact. Compared with the 145ps pure-electric Mazda MX-30, the R-EV boasts better acceleration, with its enhanced power offsetting a 58kg curb weight gain; it tips the scales at 1,778kg, with a chunk of that accounted for by the fuel tank.

Because the MX-30 R-EV is always powered by the electric motor, it always ‘feels’ like an EV to drive, even when the rotary engine is operating. Acceleration is strong and linear, response is immediate, and the character of the car doesn’t significantly alter between the two states – aided by the super-smooth, vibration-free nature of the rotary engine.

Optimized battery

The regular Mazda MX-30 uses a 35.5kWh battery. The Mazda MX-30 R-EV boasts a 17.8kWh battery – yes, exactly half the size. The company says, from a lifecycle assessment (LCA) perspective, its strategy of optimizing the battery capacity for the vehicle is better. Halving the battery also halves the cost, offsetting the addition of the rotary gasoline engine.

The WLTP-approved pure-electric range is 85km. That’s more generous than many plug-in hybrids, particularly given the compact size of the Mazda MX-30. The intention is for electric to be the weekday power source, with the rotary generator assisting for longer trips; when combined with the battery, Mazda claims a range of over 640km, courtesy of a 50-liter fuel tank.

Battery prices influenced the car while it was still in the conceptual stage. Originally, Mazda was understood to be considering a rotary range extender MX-30 R-EV, similar to the BMW i3 REX. However, the engineers concluded that a plug-in hybrid was the better solution because the range extender would have required a larger battery, affecting the affordability of the car. The plug-in hybrid concept brings a smaller battery, a larger fuel tank, a rotary engine that operates more frequently – and a price tag comparable with the BEV.

Depending on battery prices, Mazda could still roll out a range extender version but officials would not be drawn on the likelihood or timing. The focus first is the rollout of the MX-30 R-EV in Europe and Japan; officials later opined that it could even make its way to North America. Officials would also not be drawn on the possibility of a hydrogen-powered version. This is an area Mazda has been researching since 1991 and the launch of its first hydrogen rotary concept, the HR-X.

In 2010, the company won an International Association for Hydrogen Energy Sir William Grove Award for its hydrogen rotary engine initiatives. Should hydrogen infrastructure ever become viable, Mazda would almost certainly be well placed to offer a zero CO2 solution. But for now, the company remains tight-lipped.

So, against the odds once again, the Mazda rotary engine story continues. But what about the ultimate rotary Mazda, we asked – a sports car? “The dream of our engineers is that someday we will have a sports car with the rotary engine,” beamed Mazda Europe R&D center chief Kota Matsue. “But I would say that now is not the right time to think about that.”

Definitely maybe, then. Don’t bet against another surprise revival of the rotary Mazda sports car – and all thanks to the ingenious engineering purity of a plug-in range-extender urban SUV.