Far from signifying the first time McLaren has dipped a toe into the world of hybrid powertrains, the all-new Artura plug-in hybrid fires the starting gun on a number of debuts for the company and spearheads its electrified future. The P1 of 2013 was McLaren Automotive’s hybrid line-in-the-sand moment, the first time the firm sought to embrace electrification, and that car’s legacy partly inspired the Artura’s creation.

“Around 10 years ago, we were driving P1 prototypes, and McLaren’s hybrid journey started then,” says chief engineer Geoff Grose. “It has been continuing in the background ever since.” The project began five years ago, but the car differs from the 903hp plug-in P1 and 1,050hp hybrid Speedtail from 2020. Rather than being a limited-volume machine at a high price, the Artura – the name references ‘art’ and ‘future’ – is a ‘core’ McLaren product and the company’s first series-production high-performance hybrid (HPH) supercar.

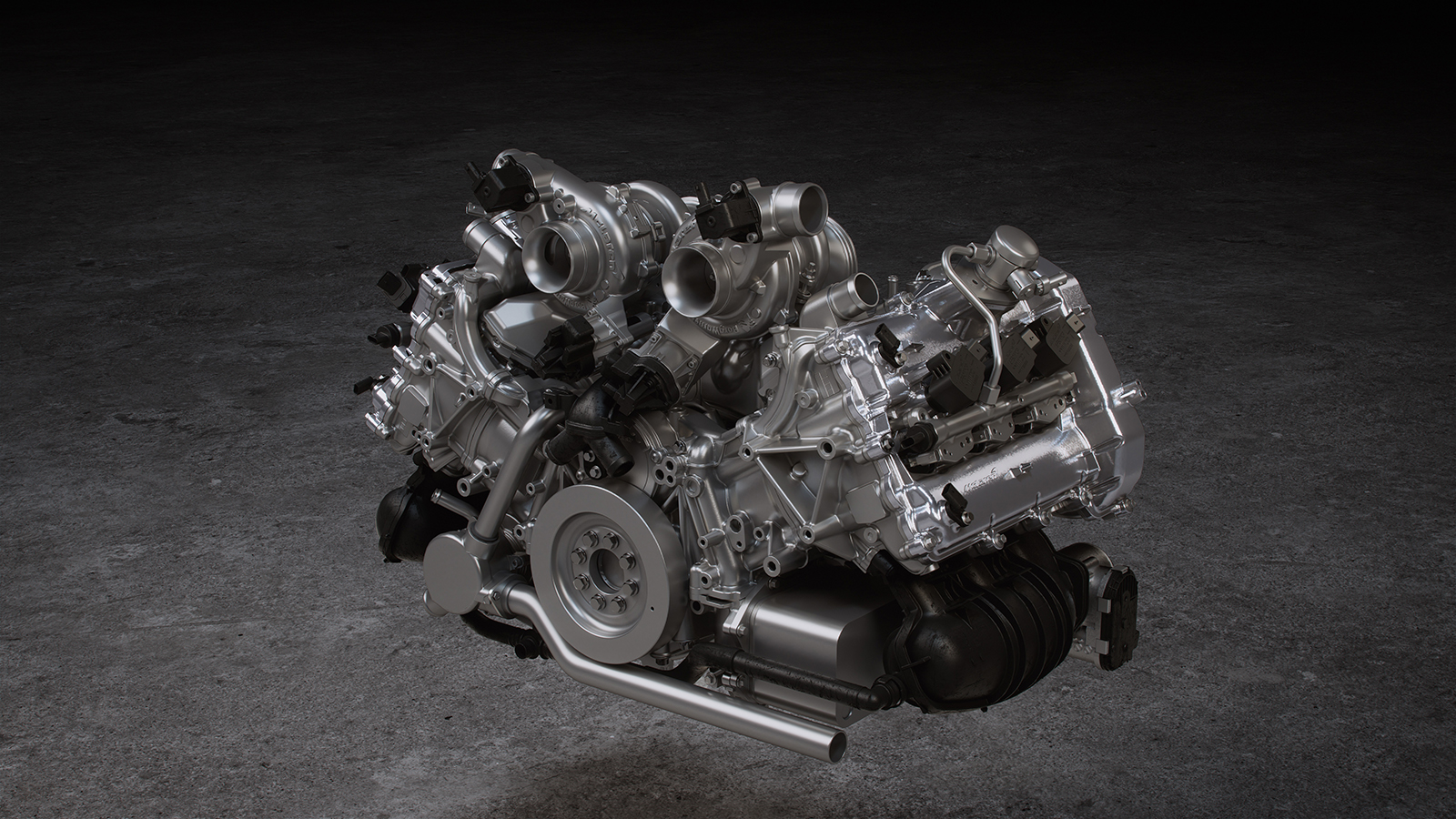

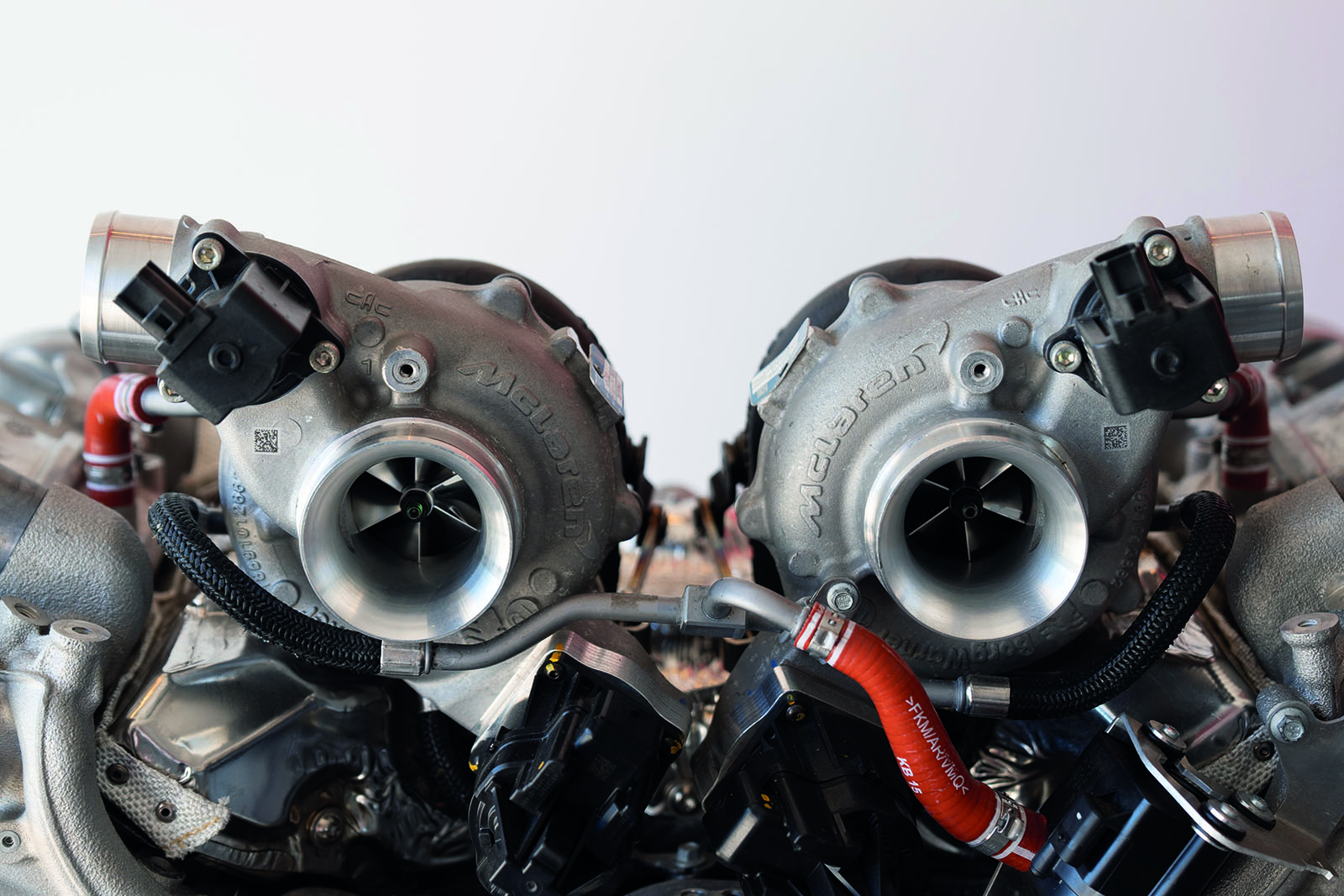

An all-new, 2,993cc twin-turbocharged V6 gasoline engine is at the heart of McLaren’s latest plug-in powertrain. The M630 unit has a very wide angle of 120°, chosen for easier packaging of the electrically actuated turbochargers inside the hot vee of the cylinder block itself, keeping the length of the unit short. Designed by McLaren but built by engineering partner Ricardo, the 585hp, 585Nm V6 sits lower than a comparable McLaren V8, aiding the center of gravity. At 160kg, the dry-sump aluminum V6 also weighs 50kg less and is fitted with a single central injector per cylinder. Gasoline direct injection at 350 bar pressure gives precise fueling for increased power and reduced emissions, with gasoline particulate filters (GPFs) and catalytic converters complying with legislative requirements.

Wide-angle layout

Revving to 8,500rpm with almost 200hp per liter, the wide-angle layout has other benefits. Engine performance can be increased by reducing the pressure losses through the exhaust system, and the M630’s design features undersquare cylinders. Grose says turbocharging efficiencies, the compact design and a desire for more specific performance determined the right engine package for electrification.

“To get the right package, we felt we could get more specific performance and keep pushing for more specific performance per liter, more performance per unit volume, and more performance for the mass of the powertrain,” he explains. “The 120° V helps keep the engine really short, because each opposing pair of conrods shares the same crank bearing pin.”

The unit’s width allowed the exhaust system to be packaged in the middle, but when compared with a completely flat engine, the V6 is slightly narrower. “This means we could build a mid-engine configuration without making everything else bigger to fit around it. It felt like a perfect counterbalance,” Grose explains.

McLaren’s lightweighting philosophy lends itself well to electrification, and the desire to shave as much weight as possible from the Artura began with the engine. “Not having separate liners, for example, means that there is not the weight of a steel liner and the extra package space,” Grose says. “In the engine, we use 3D-printed cores for the casting of the block, which means we can make the narrow gap between the cylinders even narrower and tighter.”

Because the powertrain is shorter, so is the car itself. Grose stresses, almost obsessively, that every couple of millimeters taken off the length of the car between the wheels is going to save weight everywhere. “If that’s the thing that’s driving the car to be bigger at that point, then we’re really interested in even a millimeter. It may not sound like a lot, but it has a knock-on effect to a millimeter of every other part.” Nose to tail, the Artura measures 4,539mm.

High power and torque density

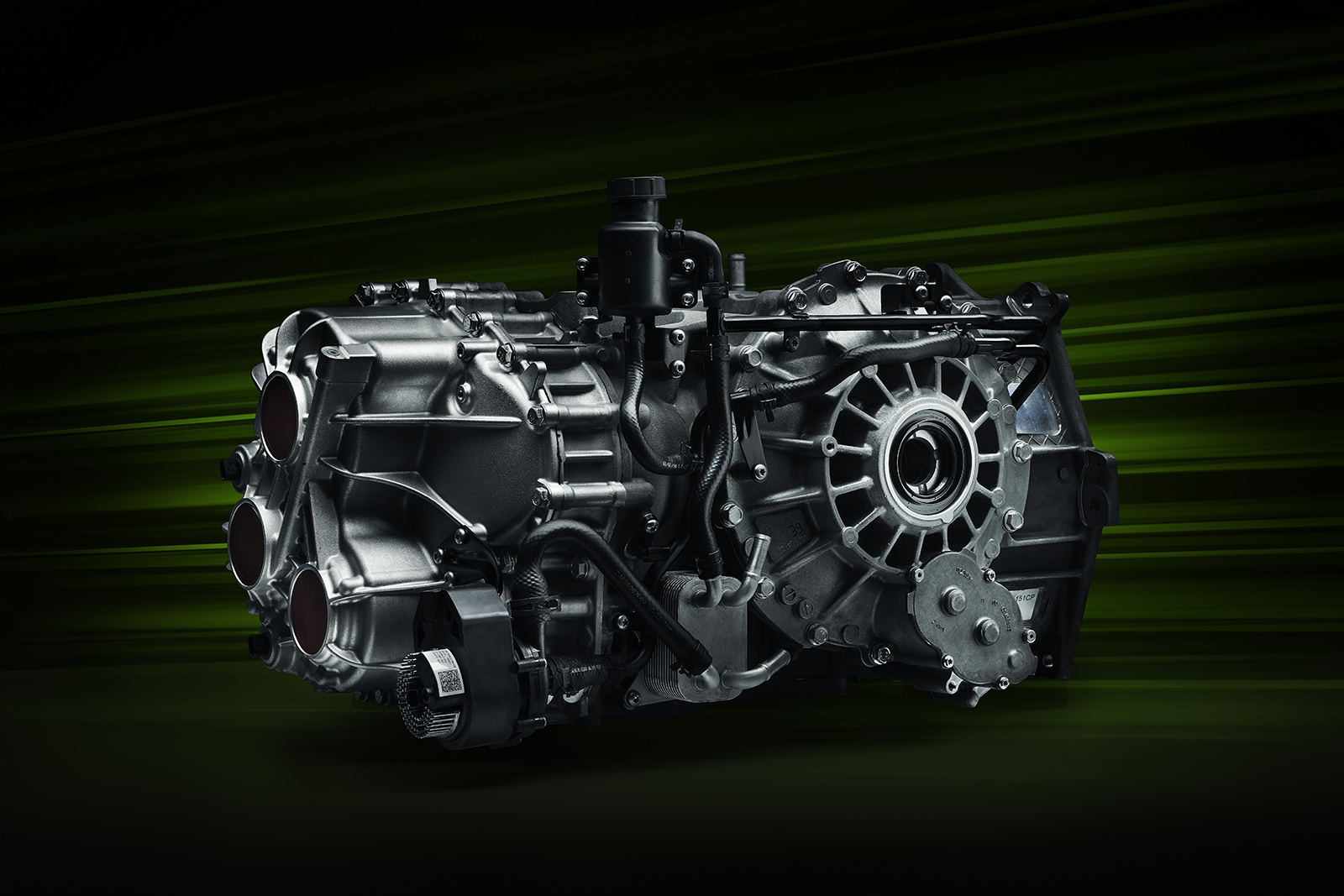

Packaged in the transmission bell housing, the 15.4kg axial flux motor is the size of a dinner plate. It is smaller and more power-dense than a conventional, radial flux e-motor, with a 33% greater power density per kilo – 4.6kW/kg – than the system used by the P1. It’s also less than half the weight of the 38kg unit used on that car. Its primary role is one of ‘torque infill’, its instant 95hp and 225Nm tailing off as the combustion engine’s power builds. In this first application of an axial flux motor in a series-production road car, the stator is sandwiched between two rotor hubs and delivers high power and torque density while being smaller and lighter.

The Artura can travel up to 31km in electric-only mode, up to a maximum speed of 130km/h. Total system output is 680hp at 7,500rpm, with 720Nm of torque at 2,250rpm, and the car lives up to McLaren’s high-performance ideal, posting a 0-100km/h time of 3.0 seconds. Top speed is a limited 330km/h, and the PHEV powertrain gives EU WLTP-certified CO2 emissions of 104g/km with economy of up to 3.9 l/100km.

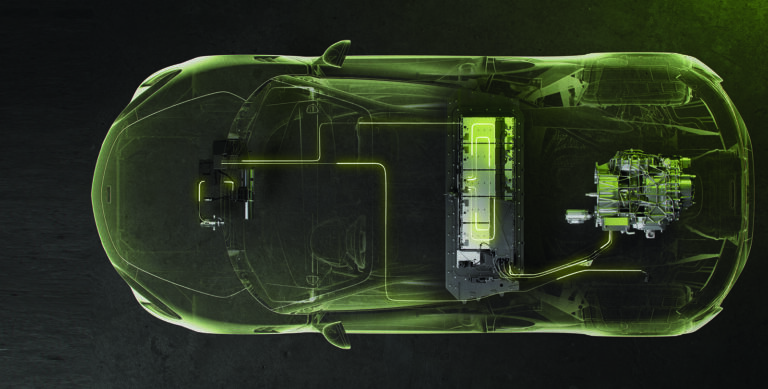

Controlling the weight was essential to enable Grose and his team to combine the PHEV powertrain but keep the car feeling like a McLaren. “Designing the car from the ground up means the high-voltage battery is where you’d expect it to be – in the middle of the car, at the floor line, where it’s going to have the least impact on any dynamic behavior in terms of roll or yaw. That’s really important,” he explains. “We also approach weight like some companies approach costs, in terms of the budget – if we’re going to spend some weight somewhere, we’ve got to save it somewhere else.”

That lightweight thinking has gone into every part of the Artura but, inevitably buried within it, says Grose, is some extra weight from the additional powertrain folded into it. The hybrid system weighs 130kg and is removed totally for the GT4 racing variant. However, savings have been made elsewhere.

The Artura debuts the all-new McLaren Carbon Lightweight Architecture (MCLA). The vehicle is clothed in ‘superformed’ aluminum body panels, and its lightest dry weight is 1,395kg. An enclosure for the 7.4kW high-voltage battery – which spans the entire width of the car – is engineered in, with the 66-liter fuel tank sitting above it. A high-voltage DC electricity supply runs to the integrated power unit (IPU) at the front of the car, and a combined DC-DC converter, onboard charger and front power distribution unit share power electronics to reduce weight further. A distribution unit inside the battery sends power to the motor control unit (MCU), which converts the battery’s DC current to AC current required by the e-motor.

Four powertrain modes

Power reserve functions never allow the battery to fully discharge, and Grose explains that even when using the car’s full performance, the battery is topped up. “If the Artura is in Track mode, it recognizes that performance is what’s wanted most from the hybrid system, so will target to just keep the battery topped up, and will fill up faster than it’s being used,” he says. Four powertrain modes – E-mode (zero emissions), Comfort (V6 and e-motor), Sport (torque infill e-motor and V6 for maximum performance) and Track (hybrid power with faster shifts from the all-new 8-speed dual clutch transmission, which drives the rear wheels and includes McLaren’s first e-diff) – enable drive tailoring. There is no physical reverse gear; this is taken care of by the e-motor. Regenerative braking only functions on the over-run, the engine providing sufficient charging. This means the brake pedal feel remains consistent.

“We were cautious to not go too far with regeneration on over-run, creating a very high drag load,” says Grose. “We want the car to feel very natural and its behavior to be consistent. When driving an electric car with a completely full battery, there’s not as much regeneration, so braking will feel different because it can’t take the energy. We don’t want a situation where behavior can’t be predicted.” Prioritizing brake feel, the Artura shuns a fully electric braking system and uses a conventional, vacuum-assisted brakes instead.

Similarities with past McLaren projects include the additional cooling requirements needed to deal with the car’s hybridized powertrain. “The way we do charge cooling is similar to how we dealt with the V8 turbo,” Grose explains. Two large, low-temperature radiators are placed at the front of the car, and the circuit can also cool high-voltage components and the intake charge air. The refrigeration circuit is used to cool the battery as well as the cabin. “That’s very efficient for us,” says Grose, “because we use a high-voltage motor to drive the compressor for that circuit, completely decoupling AC compressor speed from engine speed compared with a conventional application.

“It’s a good example of integrating high-voltage content into the car because we can run the compressor independently of whatever the driver is doing in terms of driving the car,” he continues. This means it can run at full load when stationary or in a hot environment, cooling the cabin down quickly and improving AC performance. “We also have a separate loop on that circuit to come to the battery, and we have a cold floor on the battery, and the refrigerant goes through there and keeps the battery cool,” explains Grose. The application of well optimized cooling of the battery delivers greater power and supports the consistency of the zero-emissions range.

Plugging into the past

Grose reveals that McLaren’s engineers learned a great deal about harnessing the benefits of a hybrid powertrain during the P1 and Speedtail projects. “Going after efficiency, economy and performance was part of the P1, too, as well as recognizing that drivers like to plug in the car,” he says. Although the Artura is a plug-in hybrid and hasfull PHEV capabilities, if drivers never plug the car in, it manages the battery recharging itself. The lithium-ion battery harvests power from the combustion engine during more relaxed driving scenarios, but plug in an EVSE cable and an 80% charge is achieved in 2.5 hours. Liquid-cooling techniques employing dielectric oil are used for both the battery and the e-motor, a technique carried over from the Speedtail. The battery management unit sits alongside the five battery modules, and the power distribution unit (PDU) is integrated into the battery in order to save space. Grose says that the e-motor was quite a change from previous projects: “This is different from the P1: Artura’s axial flux e-motor is mounted on the side of the engine, directly in-line in the powertrain. Because we’ve been able to make it really short, we haven’t stacked up the length of the car.” The Artura’s 2,640mm wheelbase is 30mm shorter than the V8-engined 570S and 720S models, which results in a more compact, lighter and thus agile car.