One area where all current manufacturers seem to take their own direction is the structural design of battery packs. These range from traditional fabricated, stamped steel structures, through to advanced aluminum and composite productions. The pack structure and the way in which the various modules and other ancillaries such as cooling systems are arranged can have a significant impact on the weight, size and cost of a pack.

At one extreme, there is GM’s Hummer EV, which features a behemoth 200kWh pack weighing in at over 1,000kg. Of course, a large element of this weight is the sheer number of cells needed to hit the required energy, but the rest of the pack is no featherweight. The structure is fabricated from steel pressings, welded and secured with fasteners (257 in total) – there is no use of aluminum in the double-decked design. Impressively, even the coolant hoses feature an outer, reinforced braided sleeve inside the pack.

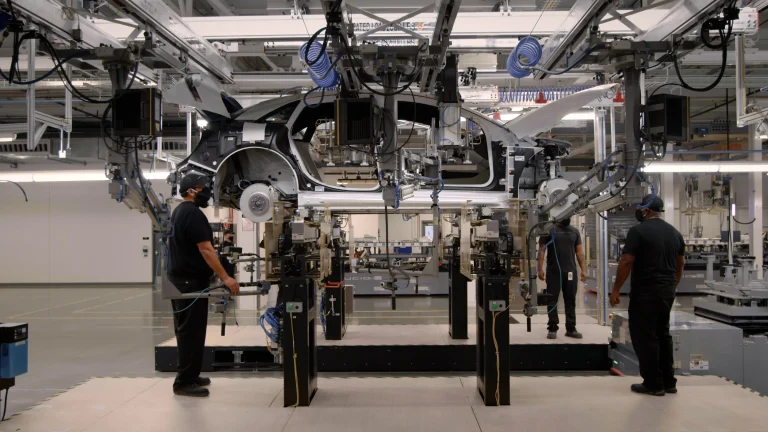

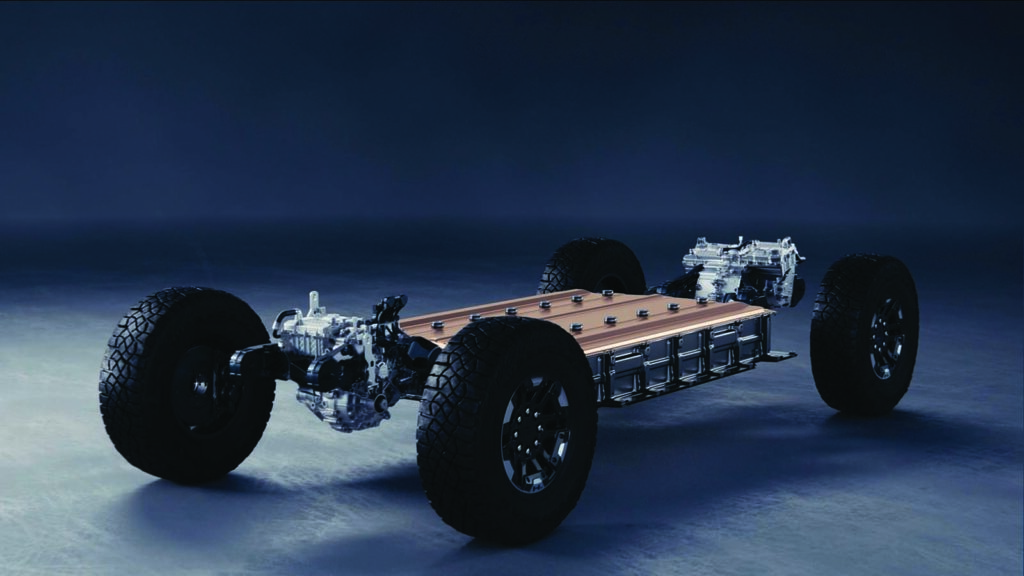

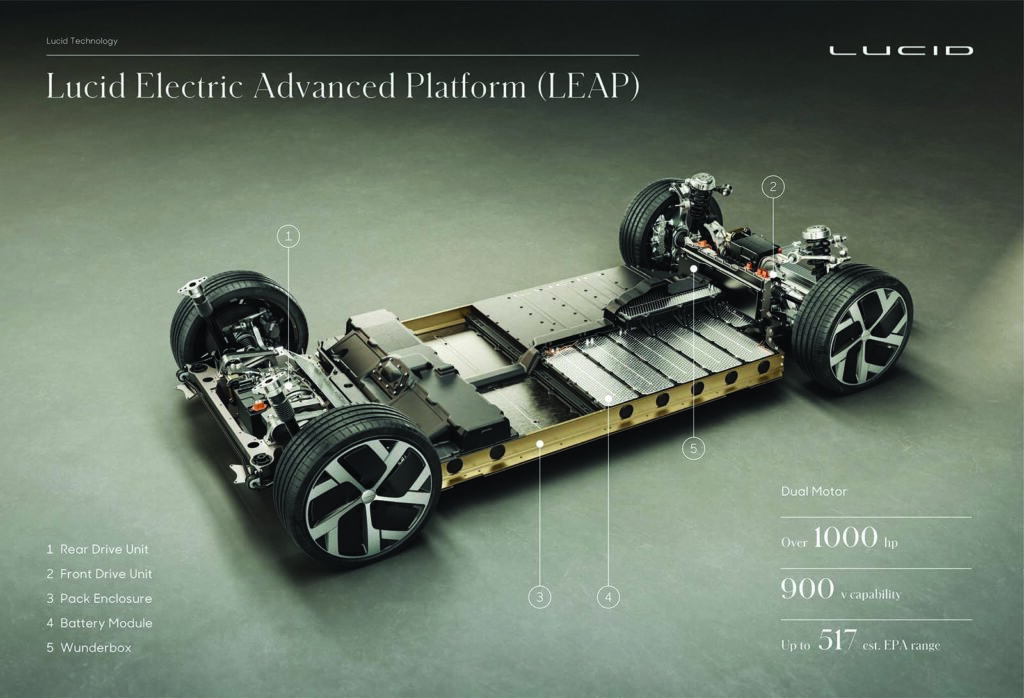

At the other end of the spectrum, there are packs such as those found in Lucid’s Air. Here, the pack structure is predominantly formed from bonded and welded aluminum extrusions, with a composite under tray (which also doubles as an underbody aerodynamic device). The overall result is a structurally robust yet relatively lightweight structure.

Notably, Lucid has also excelled with the packaging of its modules and other ancillaries, as reflected in the volumetric energy density of its pack, which comes in at 375Wh/l – impressive when compared with the next best on the market, Tesla’s Model S Plaid, which hits approximately 275Wh/l. It should be noted that the Tesla does have a superior energy density over the Lucid. Most battery packs in vehicles currently on the market are traditional in the sense that they use individual modules within the pack, with surrounding support structures and the pack split into bays dividing blocks of modules.

However, moving up an integration notch, and as displayed by Chinese manufacturer BYD among others, is the use of CTP constructions, which eliminates the modules and also packs more cells into a given volume. Depending on how this approach is executed, CTP relies on the cells to provide structure, though the line can be blurred as to whether such packs count as cell to chassis/vehicle construction.

As noted, 46mm format cells lend themselves to use in such structural packs and Tesla has deployed these in the CTP design used in the latest Model Y. Pouch cells are not really suitable for CTP designs, but prismatic cells can be used, as evidenced in BYD’s CTP ‘Blade’ design. The next logical step is the introduction of true cell to body packs whereby the pack not only contributes to the structure of a chassis, but almost entirely replaces the lower chassis structure.

Again, BYD has been at the forefront of such developments, and its e-platform 3.0 features an evolution of the Blade concept that sees the cells tightly integrated into the battery housing. The realization of structural batteries has required a host of developments, not least in terms of adhesive solutions to secure the individual cells, thermal interface materials and cooling concepts.

A common feature of packs such as BYD’s is also the use of LFP chemistries, which, despite having a lower energy density than lithium-ion, are more stable and can therefore be packaged more tightly with fewer concerns about propagation of thermal events. It should be noted that Tesla’s 4680 cells used in the Model Y pack use a lithium-ion chemistry.

Beyond these current trends, there are developments underway looking to push the structural role of batteries even further. For example, there is considerable research into laminated composite batteries,1 where carbon fibers are used as structural electrodes alongside a structural electrolyte, removing the need for individual metallic housings for cells. These batteries are still a long way from commercial reality; however, the greater use of composites within packs does offer potential for useful weight savings. This brings with it a host of associated challenges, though, not least reliably simulating composite material behavior, particularly in crash situations.

Finally, it is worth touching upon the other ancillary parts found in a pack and their contribution to pack mass and volume. For example, the use of aluminum bus bars is becoming more commonplace, thanks to their low weight and cost. However, their cross-sectional area needs to be around 50% greater than copper for a given current carrying capacity. The termination of aluminum bus bars also needs close attention because of the effect of thermal cycling on fastener integrity, due to aluminum’s greater coefficient of thermal expansion (compared with copper).

Tesla, for example, welds copper terminations onto its bus bars to negate this issue, while Lucid uses only aluminum, potentially made possible thanks to the lower ohmic heating of the bars due to its 800V system architecture. Approaches to venting of packs in the event of thermal runaway also see considerable variation across the industry.

Many manufacturers incorporate vents into the sides of packs, oriented to each module, but Hyundai’s E-GMP platform uses the seal between the pack cover and frame as a failure point in the event of pressure build-up. The ribbed seal that runs around the perimeter of the pack has compression-limiting inserts to ensure sufficient clamping to provide an environmental seal, but not so tight that gas cannot escape from inside. The downside is a more time-consuming manufacturing process than for a liquid applied sealant, but with the benefit of fewer machining processes and components needed to incorporate vents elsewhere within the structure of the battery pack.