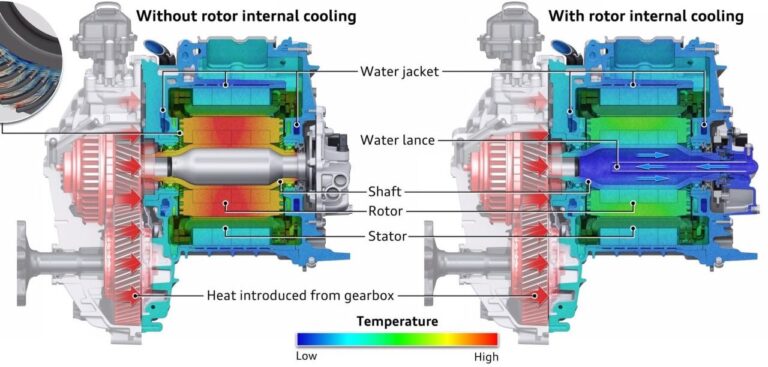

One of the USPs of Audi’s current e-tron range is the ability of its motors to sustain a high continuous power output without a need for derating. However, according to Joachim Doerr, head of electric motor and electric axle drive design at Audi, achieving this performance necessitated a highly effective rotor cooling solution. However, this was not established until well into the development process.

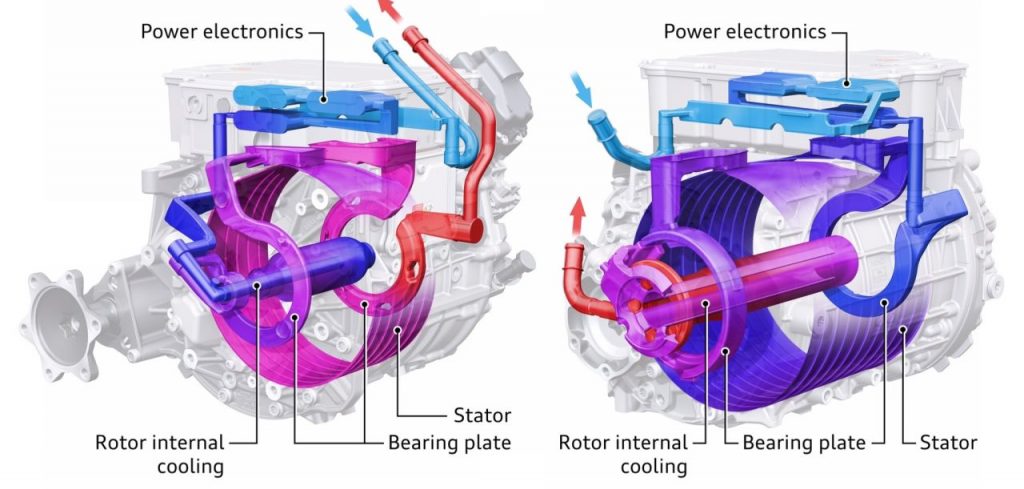

Two and a half years before the start of production, a complete redesign of the e-axle drive for rotor internal cooling was carried out, resulting in what Doerr described as “the best decision because rotor internal cooling is like a fitness program for induction motors”.

The cooling development netted many benefits, including a rise in peak power and a considerable increase in continuous power output. A further reduction in temperatures within the rotor led to improved durability of the entire unit, which in turn meant Audi’s engineers could optimize bearing clearances to improve acoustics as a result of the lower bearing temperatures.