Following two and a half years of development and some 1,000 hours of dynamometer testing, Audi Motorsport has developed an 618ps powerplant that highlights the potential of engine downsizing. The 2-liter four-cylinder can also generate a short-term 30ps power boost.

Head of Audi Motorsport Dieter Gass said, “[DTM’s] move from the naturally aspirated V8 to the turbo engine is not only important due to the additional output of some 100ps. In the DTM, we’re now driving with a high-efficiency engine of the type we’re also using in many production vehicles of the Group.”

The new Class 1 Regulations of the DTM are geared to efficiency. As in production, the development challenge was to extract the maximum from the available fuel through high compression and high efficiency.

Audi’s compact four-cylinder turbo engine with gasoline direct injection only weighs 85kg. The unit also uses standard RON 98 fuel, which aids technology transfer from motorsport to production. In addition, the engine is capable of running on e-fuels.

Each of the roughly 2,000 components of the DTM engine was designed from scratch, and the compact inline four-cylinder front engine is longitudinally mounted in the Audi RS 5 DTM.

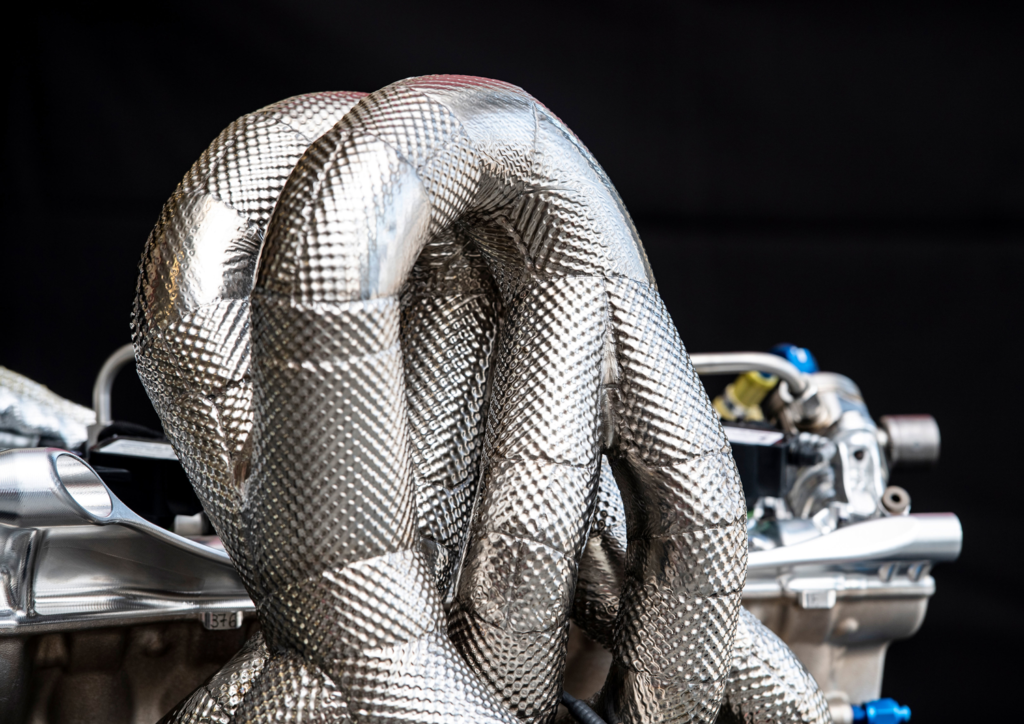

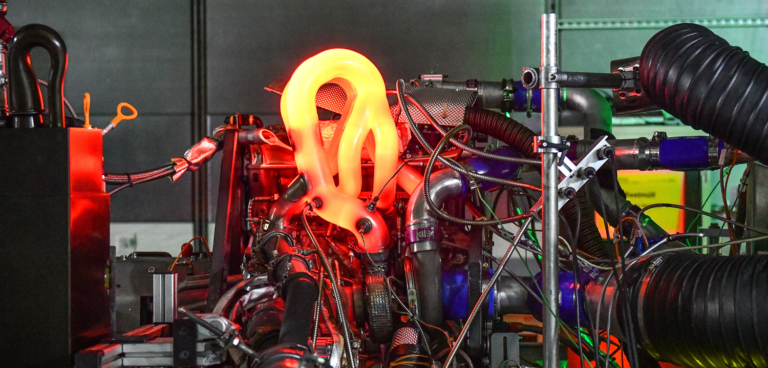

The turbocharger that operates with a maximum absolute pressure of 3.5 bar sits on the right-hand side of the car and is kept spinning by means of an anti-lag system even when the driver’s foot is not on the accelerator pedal. The powerplant’s manifolds loom high in the engine bay. Gears are shifted at 9,500rpm.