The development of next-generation, fast charging lithium-ion battery technologies is progressing at pace, with the use of silicon anode material an area of particularly intense research. Silicon has a far higher energy density potential than graphite-based anode materials, and is the only material capable of being dropped into existing cell manufacturing lines. However, to date volume manufacturing the required silicon nanostructures has proved to be challenging.

The mission of Ionic Mineral Technologies (Ionic MT) is to become the world’s leading producer of nano-silicon anode powders for the next generation of advanced lithium-ion batteries.

Based in Utah, the company is vertically integrated through control of the largest and highest-purity halloysite deposit in the world. Its open-pit mine is easily minable without the need for water, chemicals or explosives.

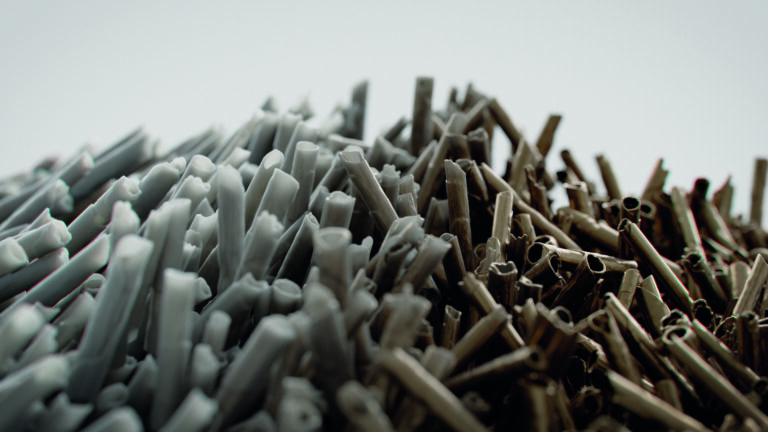

The company’s approach begins with the halloysite clay nanotube. This structure of the halloysite feedstock is what makes Ionic MT’s nano-silicon anode powder, Ionisil, unique. During the production process to create the nano-silicon, the halloysite is reduced from silica to form nano-silicon while retaining the nanoparticle morphology. This gives a critical advantage, meaning that the nano-silicon conversion occurs with significantly less energy than most competitive products and can be scaled up to 50,000+ tons per year using conventional industrial equipment.

The nano-silicon produced using Ionic MT’s patent-pending process has important customizable properties. Silicon crystallite sizes can be tuned from 5->100nm, customizing the surface area and porosities of the base silicon material.

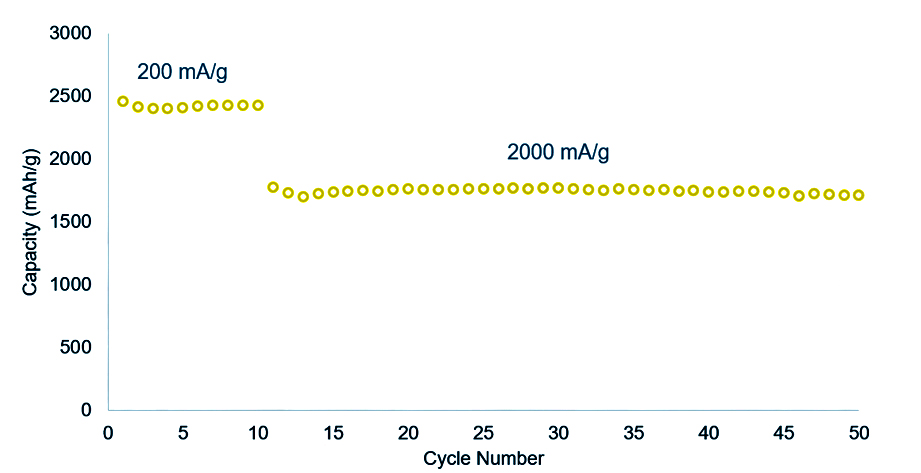

Figure 1 highlights the extremely high capacity of Ionisil (up to 2,400mAh/g) and excellent rate capabilities, achieving 1,700mAh/g at 2,000mA/g. Ionisil is a drop-in solution for partial graphite substitution to achieve capacities up to 1,000mAh/g with a 30% blend with graphite, which is a more than threefold increase over the capacity of a graphite-only anode. The company’s recent development of a surface-treated Ionisil has shown that it is possible to increase the initial coulombic efficiency of its pure silicon material to >85%, with even higher efficiencies to be expected in the near future. This work will allow increasing amounts of silicon substitution into graphite electrodes and even high-capacity silicon-only anodes.

Ionic MT will continue its commitment to electrifying the future by upsizing to its new 3,345m2 production facility in August 2023, with a target of 2,000 metric tons per annum of nano-silicon production starting in Q4 2023.