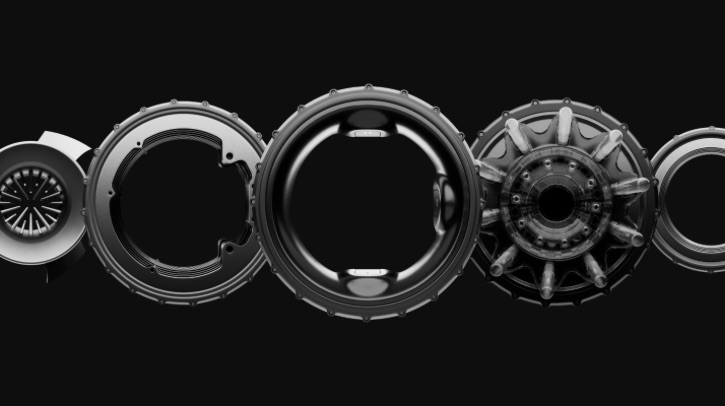

Donut Lab’s donut motor, which can be placed directly into the tire, has now been expanded into a motor family, and unveiled at CES 2025.

The new motor family features five individual models that offer the best performance on the market in all vehicle categories. The company states that a motor directly integrated with the wheel brings a solution to challenges that have long slowed down the development of EVs.

“After a long wait, we finally get to present the next-generation version of the most important component of our technology platform. Its performance capability is out of this world. Our donut motor has now also expanded into an entire motor family, which includes size options and performance classes for various uses,” said Marko Lehtimäki, CEO of Donut Lab.

Conventional powertrain systems make EVs expensive to manufacture and maintain, while reducing vehicle performance and increasing weight and complexity. A donut motor integrated directly within the tire eliminates the need for power transmission, making vehicles lighter, more economical, and easier to manufacture. In addition, another advantage offered by a donut motor is that it makes unsprung mass completely irrelevant.

Donut Lab states that its new donut motors are “the most advanced, powerful, and versatile in-wheel motors ever created“, and are lighter than existing technologies. It also states that they have the highest torque density and highest power density in the world – this means significantly more power and torque can be packed into the same weight and space than any other motor.

“Great unsprung mass has been the most important reason why everyone hasn’t used motors integrated with the tire in their vehicles. Through the torque and power density we’ve now achieved, the relative weight of the motor is so small that for the first time the unsprung mass is insignificant” said Lehtimäki.

Donut Lab is making a five-model engine family available to manufacturers that it says is “the most high-performance and versatile series on the market”. For example, the 21in version weighing 40kg can produce 630kW of power and 4,300Nm of torque – per motor. A special version of this motor for trucks has also been released.

For two-wheelers, the company released a new 17in motorcycle motor that produces 150kW of power and 1,200Nm of torque, with a total weight of only 21kg. Similarly, the 12in version of the motor is suitable for smaller two-wheelers and weighs 8kg. The fifth motor is for drones and measures 120mm in diameter, and produces 3kW and 20Nm while weighing 1,500g.

In addition to the motor, the important components that make up the modular Donut platform are battery modules, computer units and software that controls the vehicle. The company’s vision is that in the future customers will be able to select the components they need from a catalog and link them together with standard connectors quickly and simply.