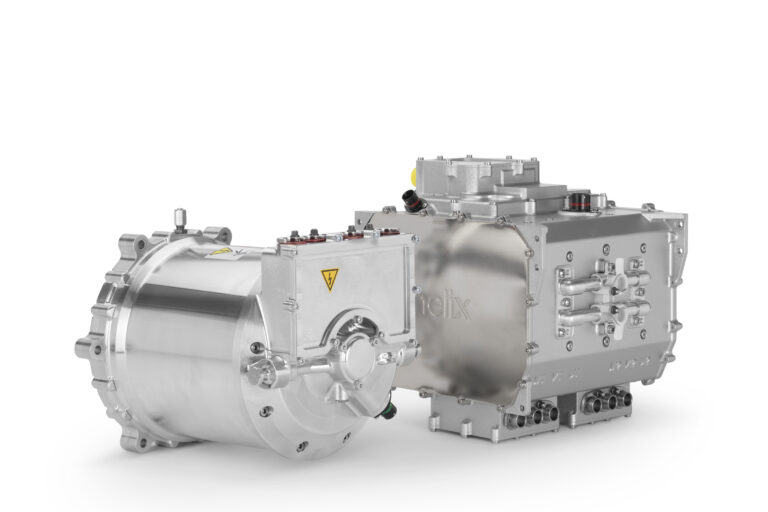

UK-based electric motor manufacturing business Helix has revealed details of its latest propulsion package: Scalable Core Technology (SCT). The SCT solution is available in stock, configured or custom formats, enabling the company to provide powertrain components which match the power requirements of its customers, right down to the exact specification.

Recently, Helix’s X-Division were tasked with manufacturing a bespoke hypercar motor under the project name REB. The product, named the SPX177, is the most powerful pure battery-electric vehicle motor produced by the company to date, weighing just 28kg but delivering 650kW of continuous power.

“It uses the ‘top end’ in materials and reaches back into our motorsport heritage,” explained Derek Jordanou-Bailey, chief engineer at Helix, who took overall responsibility for the project. “Our SCT is intended to deliver products that are tailored to customer requirements and easily manufactured in large production runs, but for REB the focus was on ultimate performance, accepting that the machine would be more demanding to manufacture in anything more than smaller batches. In those terms, it is like an F1 or Formula E unit.

“It’s small and weighs just 41kg, including the 13kg inverter. It is a 2x 3-phase motor, so its current is shared across two inverters, a necessary approach to meet the phase current demands at ‘normal’ DC voltages at this extremely high power level. Both the motor and inverter have extremely high power density. Six high-voltage cables connect the inverter to the motor, while an LV connector carries the various control signals.”

Jordanou-Bailey confirmed that the motor achieved more than 700kW on the test stand and that it could deliver more, but the company did not want to push it further than required. Compared to the internal combustion engine installed in the McLaren Artura, for example, the SPX177 weighs just 1/7th for the equivalent continuous power output, although the battery does weigh more than the vehicle’s fuel storage. Other advantages include the low mass of the SPX177, which provides vehicle designers with additional design freedom in terms of where it is installed, optimizing center of gravity and aerodynamics.

“The customer told us what peak power they wanted and demanded a very high steady-state output,” said Jordanou-Bailey. “Right now, it is tricky to deliver sufficient energy to maintain that level of output, but in time it is likely to be possible and the customer wanted to ensure their flagship model was ready for that.”

He added, “We needed an architecture that minimizes losses and the heat generated, especially at high speed, and that meant quite a change in the way the motor was wound, since minimizing resistance losses results in a very low inductance machine. The switching in the inverter can generate lots of noise and harmonics and this is more challenging with a low inductance motor. The software team did a great job developing a new way of controlling the phase currents in the motor.”

The REB project was carried out by a team of 12 engineers and was completed in just over two years. At present, a proposal for a small production batch is underway, with Helix currently supporting the integration of the power unit into the customer’s hypercar.