Audi has announced it has started the manufacture of electric motors for the brand’s new Premium Platform Electric (PPE) in Győr, Hungary.

The motors will be used for the first time in the Audi Q6 e-tron series, which is scheduled to start production at Audi’s Ingolstadt headquarters at the end of the year.

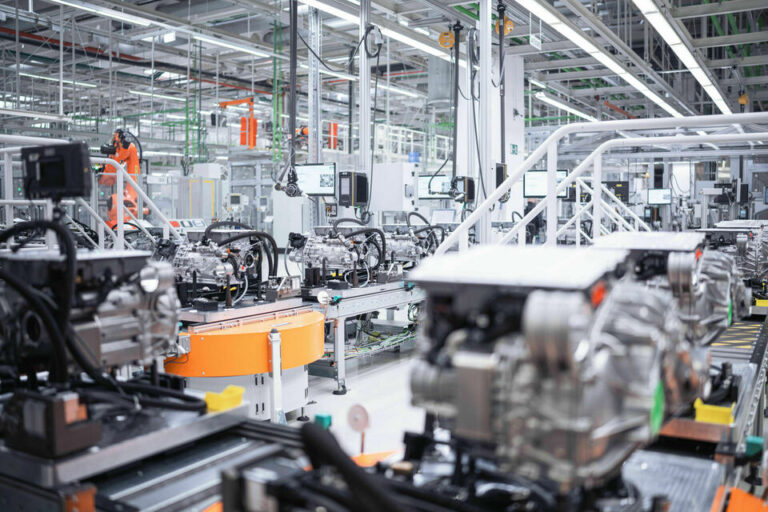

Among other provisions, the company has set up its own battery assembly facility in Ingolstadt in preparation for this step. In Győr, Audi Hungaria is producing stators and transmission components in a completely new production area, where the axles for the PPE are also assembled.

“Győr is predestined for the production of these highly compact and efficient electric motors for the PPE,” stated Audi CEO Gernot Döllner. “The highly qualified team at the site has already built over 400,000 electric drive systems since 2018, which is invaluable experience.”

In addition to the electric motors for the PPE that power the Audi Q6 e-tron series, Győr is also building the drive system for the Audi Q8 e-tron. Furthermore, an additional production area is being set up for electric motors that will be used in vehicles based on the MEBeco (modular electric drive toolkit) in the Volkswagen Group.

To produce the electric motors for the PPE, the brand has installed three new lines. The production line for stators has 28 work steps, the one for transmission components has 15. One axle alone requires 190 individual steps to assemble. Around 700 employees are involved in production.

In terms of series production, the employees in Győr work in three shifts to build up to 2,000 electric motors per day for the PPE. The site supplies both Audi and Porsche. Compared to the previous electric motor assembly facility, the vertical range of production has been increased.

“The start of production in Győr marks an important milestone in the ramp-up of production of the Audi Q6 e-tron,” said Audi board member for production and logistics Gerd Walker.

“I know from personal experience how passionately the team at Audi Hungaria works and how systematically it advances the further electrification of the world’s largest engine plant. With its enormous expertise in drive systems and net carbon neutral production, the Győr site is an indispensable part of Audi’s global production network,” added Walker, who was managing director for vehicle production at Audi Hungaria from 2012 to 2016.