Details have been announced of a €6.5m (US$7.7m) project that aims to develop an automated battery exchange station for heavy-duty commercial vehicles. The collaborative eHaul project will be led by TU Berlin alongside partners including the Fraunhofer Institute for Transportation and Infrastructure Systems; it will be funded by Germany’s Federal Ministry for Economic Affairs and Energy.

Batteries are not yet capable of covering the long-haul journeys of heavy-duty vehicles on a single charge. Therefore, a solution is needed to reduce downtime for fleets, which the eHaul project seeks to provide via a feasibility study and, eventually, a network of battery exchange stations.

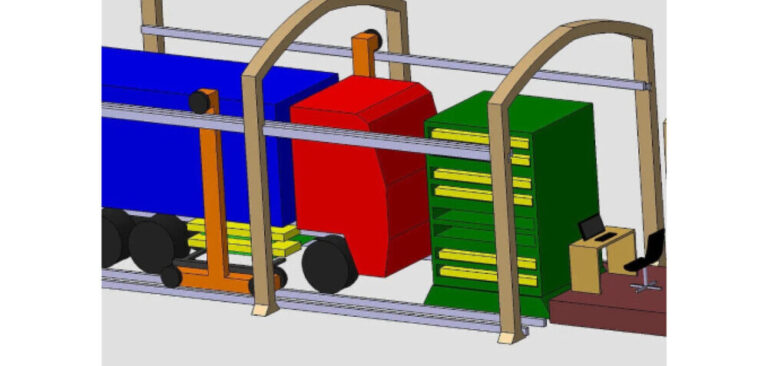

During the project, which is set to end in September 2023, a pair of electrified trucks will be commissioned by the consortium for use by two logistics companies. Alongside this, a battery exchange station will be developed in south Berlin for use by the fully electric commercial vehicles, with the final goal being to fully automate the system.

A truck will arrive at the station when a replacement battery is needed. A robotic system will swap the drained battery for a fully charged replacement, dramatically reducing downtime because vehicles do not have to wait while batteries charge.

As the project progresses, an array of sensors will gather and record data from the two electric trucks, such as energy consumption of the engine, load capacity and altitude profile of specific routes.

Stefanie Marker, head of the chair of naturalistic driving observation for energetic optimization and accident avoidance at TU Berlin, said, “In a real-life test, we then want to determine whether 40-ton electric trucks with exchangeable batteries are actually a viable alternative, including when daily trips of more than 300km are involved.”