Bosch has developed an electrified axle that can be integrated into semi-trailers. Integration of an electrical machine into the semi-trailer axle creates the opportunity to capture electricity under braking, which can be fed into the trailer’s power units – an application particularly suited for commercial refrigeration vehicles.

Bosch estimates that a cooling unit powered by this recovered energy can yield a cost saving of as much as €10,000 (US$11,695) per year.

“Bosch is making trucks’ rear axles electric and smart,” said Markus Heyn, member of the Robert Bosch board of management. “Our electrification solution for trucks makes economic sense and shows how electromobility can work even in today’s trucks.”

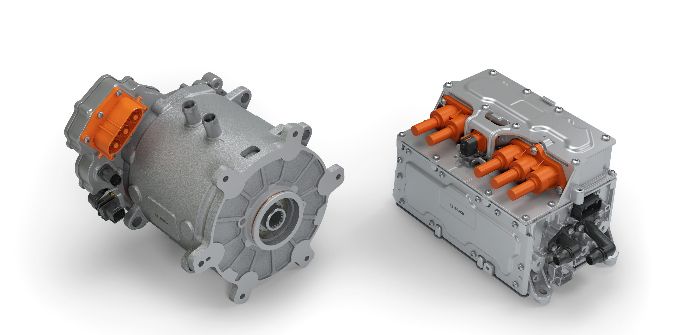

The energy recovery axle technology is available on new solutions, but also as a retrofit service. The electrified axle uses components from passenger cars. The SMG180 electric motor used in the application is already utilized in large numbers of electric and hybrid vehicles, such as the German postal service’s StreetScooters.

However, in the truck axle application, the electrified system is only in use when energy can be recuperated – such as under braking or when traveling downhill. The collected energy is stored in a high-voltage battery, and can then be fed into the vehicle’s motors (for example, during hill starts) or to the trailer’s refrigeration unit.

The electrified axle also represents an important step toward the company’s vision of automated trailer parking. The addition of a powertrain to the electric axle would make it possible to move container trailers without a tractor.

“Bosch’s electrified axle makes trailers independent,” added Heyn. “By electrifying trailers, Bosch is taking an important step toward automated parking at freight depots.”