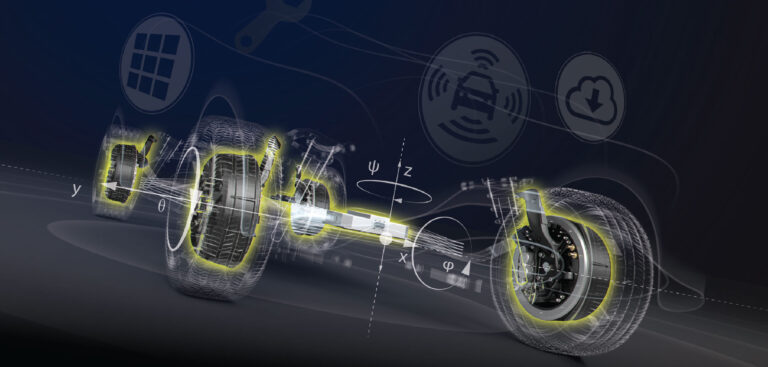

With a shared vision of supporting a new sector of highly efficient and hyper-responsive EVs, Elaphe and McLaren Applied will work in partnership to deliver an in-wheel propulsion system that will use McLaren Applied’s inverter technology and Elaphe’s direct-drive in-wheel motors and vehicle controls.

The pair claim that the combined in-wheel propulsion system will provide best-in-class long-range cruising efficiency and unparalleled vehicle controllability. Furthermore, the torque response will be five times faster than currently available systems.

Elaphe’s in-wheel propulsion system technology has proved itself in the Lightyear Zero and Aptera vehicles by achieving superior energy efficiency of more than 97%. The company’s in-wheel technology benefits from torque densities of up to 460Nm/liter and 100Nm/kg and uses a high control bandwidth on each wheel to enable excellent safety capabilities. Elaphe’s system consists of super-efficient, robust in-wheel motor technology, advanced direct-drive motor control software and safe multiple-wheel drive controls.

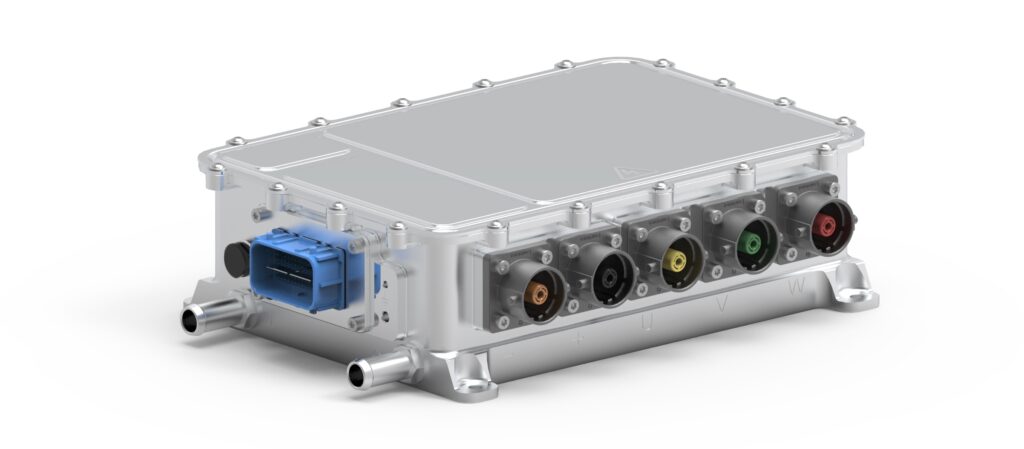

McLaren Applied supplied inverters for the McLaren P1 in 2012 and for Formula 1 and Formula E since 2013 and has now brought its technology to the wider automotive sector with its next-generation IPG5 800V silicon carbide (SiC) inverter. The IPG5 delivers excellent gravimetric and volumetric power density of 90kVA/kg and 130kVA/L respectively, variable switching frequency and efficiency of up to 99%.

Elaphe and McLaren Applied aim to add value to the next generation of EVs by enabling space and weight savings, resulting in excellent vehicle energy efficiency with minimal aerodynamic drag and lower rolling resistance.