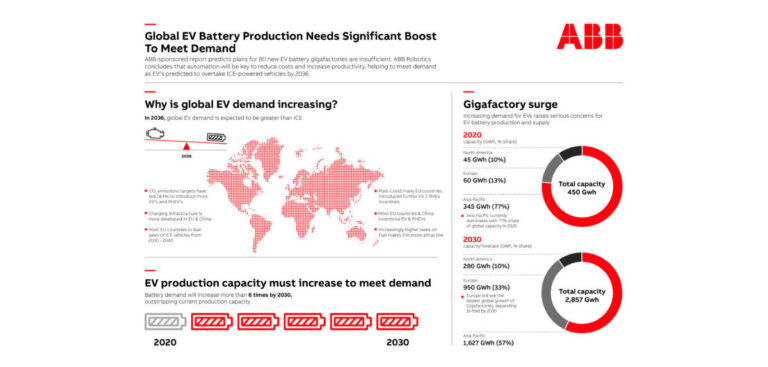

An ABB-sponsored report predicts that proposed plans for 80 new gigafactories set to manufacture EV batteries will be insufficient and highlights the role that automation will play in meeting consumer demand, as electric vehicles sales are expected to overtake ICE vehicles by 2036.

The Electric Vehicle Battery Supply Chain Analysis report, authored by the automotive intelligence unit of Ultima Media, voices concern about EV battery supply to meet the rapidly growing market, and the serious risk that poses to the growth of clean propulsion fuels and options, despite the planned gigafactories.

At present, Asia is leading EV battery production, with European manufacturing capacity expected to grow in the next few years alongside the USA, where plans are also being put in place to expand production.

“Automation is key to increasing assembly safety, quality and traceability and delivering battery technologies cost effectively, which is critical to the expansion of electric vehicles.” said Tanja Vainio, managing director of ABB Robotics Auto Tier 1 business line.

“With production speed and flexibility essential to the successful scale-up of the EV battery industry, our cellular production architecture enables manufacturers to quickly validate a cell design and then roll out production cells globally with uniform quality, safety and productivity standards. Rollouts can be scaled to demand with the flexibility to adjust capacity in real time.”

Within the report, researchers state the importance of battery pack assembly stations being very close to, or actually within, manufacturer’s facilities.

“Co-locating battery pack assembly not only boosts sustainability by reducing transportation, it increases flexibility. A cellular approach to production is easily integrated alongside existing lines,” added Vainio.

“If the demand curve moves, cells can be added or removed quickly to maintain accurate production scale. Our robots are designed to be quickly repurposed as needed, boosting flexibility and adding to our sustainable approach by maximizing the life of each robot we build.

“We believe that building a robust battery supply chain will create a distinct competitive advantage for OEMs, setting a trend toward maximum production flexibility, whether battery pack production is insourced or outsourced, to further reduce costs and boost productivity.”

Reducing vehicle cost has become an industry focus due to the high price of EVs currently preventing further market penetration. ABB is focused on providing solutions that improve battery manufacturing productivity, as EV batteries can represent up to a third of an entire vehicle’s cost.

“Increasingly we see that higher productivity and lower costs are driven by assembling battery cells straight into packs,” concluded Vainio. “ABB is working in partnership with a number of manufacturers, using its systems and knowledge to increase productivity, quality and safety levels, as well as reduce finished pack costs through automated assembly – vital if EVs are to meet their required cost and adoption targets.”

The Electric Vehicle Battery Supply Chain Analysis examines the current and future state of EV battery supplies, the sources of materials, current technologies available and demand analysis and potential risks.