UK-based Swindon Powertrain originally forged its reputation in motorsport, most notably the British Touring Car Championship (BTCC) and World Rally Championship (WRC), where its engines have been responsible for a plethora of race wins. However, in recent years, it has branched out into mainstream automotive development, including electrification, playing to its strengths by catering primarily for niche vehicle applications.

The first product of this move was the HPD E range (HPD standing for high power density), which incorporates both an electric drive motor and reduction gear transmission in a package tailored to front-wheel drive applications. Launched in 2020, the company showcased the system in a classic Austin Mini EV conversion with an 80kW unit. It has gone on to produce both a complete conversion kit for the Mini and supply various companies globally with e-motor-gearbox systems for other applications, including Aston Martin for EV conversion of classic DB4s. It also added a standalone e-transmission to its range for use in low-volume production vehicles.

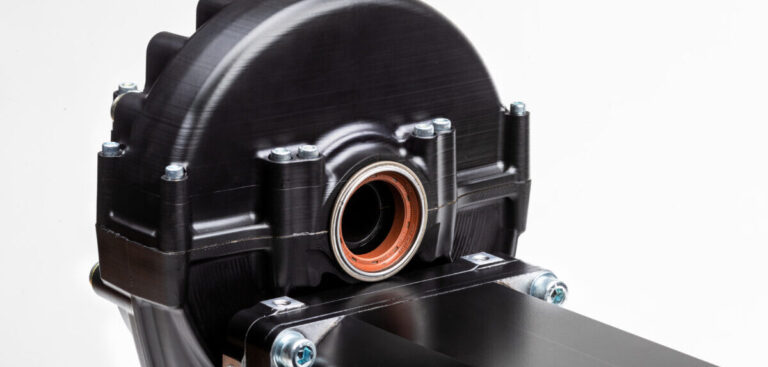

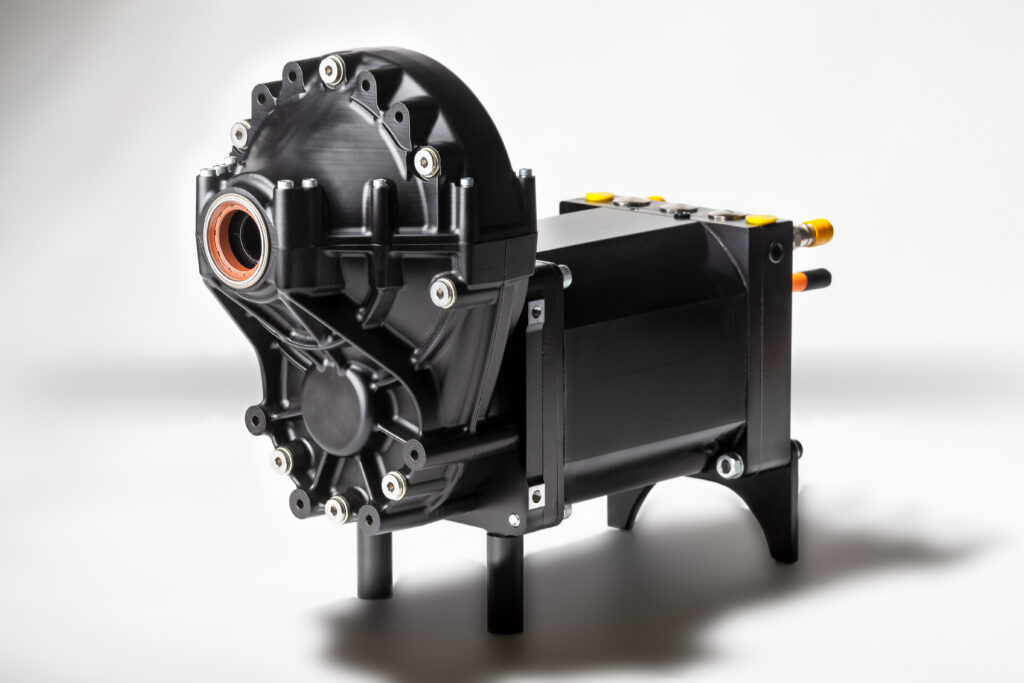

The company has now taken the HPD E concept a step further, introducing the HPD L, a system designed for both rear or all-wheel drive applications, and available in a range of outputs with initial offerings up to 240kW. Talking to EPTi, company CCO Gerry Hughes, whose past roles have included head of manufacturer NIO’s performance program and Formula E team principal, explains the reasoning behind the new developments.

“Once we’d launched the HPD E, we had a huge amount of interest from all across the world, but particularly North America, and they wanted a powertrain solution for front engine, rear wheel drive. They also wanted a solution for higher power electric motors.” The result is a range of integrated e-motor/transmissions from 80kW to 240kW, which, says Hughes, suit applications from classic car conversions though light commercial vehicles up to heavyweight, American muscle cars.

Application flexibiity was the name of the game for Swindon, and to achieve this the HPD L is available in two variants, RWD and AWD, with a choice of two reduction gearbox ratios and the option of either an open or limited slip center differential. “We tried to look at as many vehicles as possible and of course, the reduction gear ratio has to be factored in with whatever the final drive ratio is at the rear, or both axles in AWD,” states Hughes. “Clearly, from a packaging perspective we can’t incorporate every ratio under the sun, at least not off the shelf, but we do undertake bespoke work with niche manufactures and OEMs.”

Application flexibiity was the name of the game for Swindon, and to achieve this the HPD L is available in two variants, RWD and AWD, with a choice of two reduction gearbox ratios and the option of either an open or limited slip center differential. “We tried to look at as many vehicles as possible and of course, the reduction gear ratio has to be factored in with whatever the final drive ratio is at the rear, or both axles in AWD,” states Hughes. “Clearly, from a packaging perspective we can’t incorporate every ratio under the sun, at least not off the shelf, but we do undertake bespoke work with niche manufactures and OEMs.”

The units have also been designed to maximize installation flexibility and to this end the aluminum casings feature multiple M8 threaded mounting points, while the transmission output drive flanges are of a universal design. Intended to operate at around 350V, the e-motors used in the system are radial flux, IPM units with cooling provided by a liquid glycol-distilled water mix, which can be on a shared circuit with the inverters. The most powerful 240L setup weighs in at 65kg.

Hughes notes that Swindon is able to offer an end-to-end solution for e-drives, including cooling pumps, and it has an established relationship with Cascadia Motion for inverter supplies, though customers can specify their own choice of power electronics. However, he points out that it is not a battery manufacturer. “That’s an area where there are people that are better placed and better resourced and better skilled to do volume manufacture,” he admits. That said, it will undertake battery pack design for niche vehicle manufacturers if necessary.

HPD 128 L Technical Data

E-Motor Type: IPM

Peak Power Rating (kW): 128 @ 10,300 rpm

E-Motor Continuous Power Rating (kW): 80

E-Motor Max. Torque (Nm): 136

E-Motor Max. Efficiency (%): 97 @ 8,000 rpm

Max. E-Motor Speed (rpm): 15,000

E-Transmission Lubrication System: Splash Lubrication (Optional Oil Cooler)

E-Transmission Oil Capacity (L): 0.5 (W/O Optional Oil Cooler)

E-Transmission Output Drive Configuration: RWD or AWD

E-Transmission Central Differential Specification (AWD): Std or LSD

E-Transmission Reduction Gear Ratios: 3.368: to 4.5888:1

Max. Output Torque (Nm): 458 or 624

Max. Output Speed (rpm): 4,454 or 3,269

Output Drive Flange(s): Universal Propshaft Coupling (s)

Motor Power & Torque Curves (400V)

HPD 240 L Main Technical Data

E-Motor Type: IPM

Peak Power Rating (kW): 240 @ 9,000 rpm

E-Motor Continuous Power Rating (kW): 190

E-Motor Max. Torque (Nm): 269

E-Motor Max. Efficiency (%): 97 @ 8,000 rpm

Max. E-Motor Speed (rpm): 15,000

E-Transmission Lubrication System: Splash Lubrication (Optional Oil Cooler)

E-Transmission Oil Capacity (L): 0.5 (W/O Optional Oil Cooler)

E-Transmission Output Drive Configuration: RWD or AWD

E-Transmission Central Differential Specification (AWD): Std or LSD

E-Transmission Reduction Gear Ratios: 3.368: to 4.5888:1

Max. Output Torque )Nm): 906 or 1,234

Max. Output Speed (rpm): 4,454 or 3,269

Output Drive Flange(s): Universal Propshaft Coupling (s)

Motor Power & Torque Curves (400V)

Dimensions

The HPD 128 L Powertrain System Dimensions are:

335 x 250 x 439mm.

The HPD 128 L Powertrain System Mass is:

42kg (Dry)

The HPD 240 L Powertrain System Dimensions are:

335 x 250 x 564mm.

The HPD 240 L Powertrain System Mass is:

65kg( Dry)