Federal-Mogul Powertrain has launched a new electrification strategy for medium- and heavy-duty vehicles.

Led by its Controlled Power Technologies product group, the company has developed a cost-effective, fully scalable, modular approach that can be optimized for each commercial vehicle segment and application. The technology portfolio has been designed for individual customization and integration to meet the specific needs of the engine manufacturers.

“One of the key questions that motivates us at Federal-Mogul is how we can improve fuel economy and CO₂ emissions in commercial vehicles by harvesting waste energy, including both vehicle kinetic energy that is lost during braking and exhaust gas energy. Our solution must include how to then store it efficiently and return it to do useful work,” said Gian Maria Olivetti, CTO, Federal Mogul Powertrain.

Diesel engines are efficient in a steady state but are substantially less efficient during transients. Instead of trying to replace or supplement the internal combustion engine (ICE) with an electric traction motor, the Federal-Mogul engineers are using electrification to further enhance the efficiency of the ICE, both during steady-state operation and particularly to improve the fuel economy and emissions impact of challenging transient conditions.

In the new approach, the engineering team is supplementing kinetic energy recovered through an engine or driveline-mounted generator by electricity generated from a carefully controlled exhaust-driven generator. Energy is then returned either through an electric motor supporting the driveline or by electric supercharging.

Independently-conducted tests have shown that a highly-responsive Federal-Mogul motor-generator as small as 12kW applied to the engine or driveline can enable fuel savings of up to 8% on a full-size bus by recuperating energy as the vehicle decelerates and boosting the engine’s torque as it accelerates.

Federal-Mogul’s engineers are seeing further opportunities for waste energy recovery by electrification of the air-loop system. While turbocharging recovers some of the 20-30% of the fuel’s energy that leaves the engine in the exhaust gas, there is still more to be captured and returned.

“Simple, cost-effective exhaust gas energy recovery requires a control system that avoids harvesting events that are harmful to the performance of the base engine or damaging to the generator itself or to the aftertreatment system,” said Nick Pascoe, managing director of Federal-Mogul Controlled Power.

The onboard electrical energy, ideally recovered from the vehicle’s kinetic energy or exhaust gas, can be used to improve the dynamic response of the airflow by electric supercharging.

This can enable engine-downsizing, improve emissions and additionally yield up to 5% fuel economy improvement by reducing pumping losses combined with improved fueling and re-optimized gear shift strategies.

“The first few tenths of a second during a transient event, when the combustion system is most heavily challenged, are the worst with regards to the production of toxic emissions, including NOx and particulates,” explained Pascoe.

“The latest fuel systems can respond far more quickly than the airstream, so our strategy allows more benefit to be derived from existing investments in these highly capable vehicle technologies. By speeding up the supply of air to match the response of the fuel system, we can improve both fuel economy and emissions performance by maintaining better control of the air-to-fuel ratio.

Rigorous, high-speed control of air-to-fuel ratio is also vital for avoiding detrimental effects to the base engine performance and for managing the temperature and chemical composition of the exhaust gas.

The key elements in the air-loop electrification approach are the company’s Turbo-generator Integrated Gas Energy Recovery System (TIGERS) and Controlled Boosting for Rapid Response Application (COBRA).

The Turbo-generator Integrated Gas Energy Recovery System combines an exhaust-driven turbine and liquid-cooled Switched Reluctance (SR) generator to produce a proven, technically mature system that seamlessly converts exhaust gas energy into electrical energy.

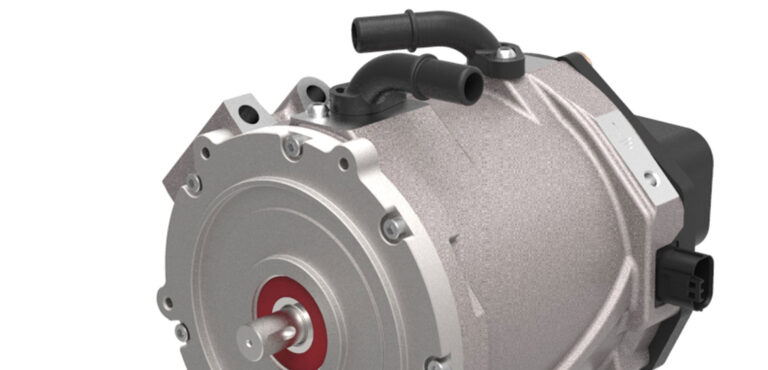

Controlled Boosting for Rapid Response Application liquid-cooled electric superchargers provide the engine with on-demand air supply, offering low rotor inertia and excellent thermal management.

When combined with the company’s CPT SpeedTorq electric assist motor/generator technology, the portfolio offers a modular approach that enables the optimum solution to be specified for each vehicle weight and application.