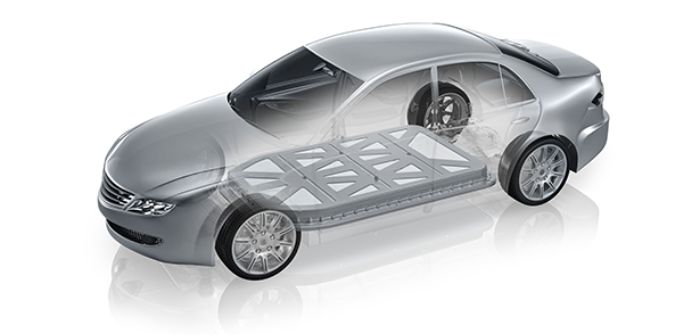

Engineering and mobility company FEV and aluminum hot sheet forming specialist Impression Technologies (ITL) have presented a battery housing concept for electric vehicles. Using Hot Form Quench (HFQ) technology, the solution optimizes the space required for storing batteries.

The battery housing concept works by placing all of the structurally relevant components on the outside and integrating the battery housing into the overall vehicle. This creates space for additional batteries and provides greater range or, alternatively, enables a battery installation that takes up less space while delivering the same amount of range.

“With our latest battery housing development, we are once again showing that FEV is thinking in many directions when it comes to sustainable mobility,” said Professor Stefan Pischinger, president and CEO, FEV Group. “We offer solutions that the market demands – for example, to increase the range of e-mobility. With ITL, we have the ideal partner for lightweight construction on board for this project to make the concept tangible for our customers and partners in the form of a demonstrator in a timely manner.”

The required structural performance of the solution is delivered using an exoskeleton concept, which “realizes a power flow above and below the battery pack”, FEV says. This keeps loads which may occur in a crash away from the installation space used for the battery cells, in addition to enhancing the rigidity of the overall system – including the battery and the bodyshell.

The required structural performance of the solution – with its complex structures with low radii and draft angles – was made possible using ITL’s aluminum HFQ technology. FEV and ITL plan to manufacture and present a physical demonstrator in the coming months.

“The HFQ technology expands our portfolio of possible manufacturing technologies for new developments and enables us to implement more complex structures compared to cold forming technologies,” said Christian Kürten, head of vehicle architecture, FEV Vehicle. “Added to this is the use of high-strength aluminum alloys, which, in conjunction with the HFQ process, ultimately deliver the required performance in optimized installation space.”

“FEV’s pioneering approach to design excellence and open-mindedness in developing new lightweight concepts and solutions for electric vehicles is a great fit for ITL and the benefits of HFQ’s lightweighting technology,” said Jonathan Watkins, CEO, Impression Technologies. “With our expertise in ultra-high strength aluminum alloy characterization, design-for-manufacture, forming simulation and production, and FEV’s global network in the automotive industry, we complement each other perfectly and ensure that all automotive manufacturers can benefit from the novel battery housing concept.”