Ford and SK Innovation have signed a Memorandum of Understanding (MoU) to start a joint venture named BlueOvalSK. By the middle of the decade, the collaboration aims to produce around 60GWh each year in traction battery cells and array modules, with the potential to expand in the future. Around US$5.3bn (₩6tn) will be invested by the pair.

“This MoU is just the start. It’s a key part of our plan to vertically integrate key capabilities that will differentiate Ford far into the future. We will not cede our future to anyone else,” commented Jim Farley, Ford president and CEO.

The next-gen cells and arrays will be used to power several of Ford’s future battery electric vehicles, with the US company’s BEV plan alone calling for a minimum of 240GWh of battery cell capacity by the year 2030. It is estimated that a region such as North America will require 140GWh, while the remaining balance will be divided between Europe and China.

“Global auto makers have praised SK Innovation’s EV batteries for their safety, high capacity and long life,” commented Jee Dong-seob, head of SK Innovation’s battery business. “SK Innovation will be supplying batteries for the fully electric version of Ford’s legendary and best-selling F-150 pickup truck. We are thrilled to be supporting the electrification of a vehicle that represents the very best of American auto making.”

In 2016, SK Innovation developed its first NCM-811 battery and has since developed the world’s first Nickel 9 battery that contains 90% nickel content. These products are to be mass-produced in the USA to power the Ford F-150 Lightning. Originally SK Innovation planned to secure more than 125GWh of annual capacity by 2025, but with the help of the joint venture, it now expects to reach a target of 190GWh instead.

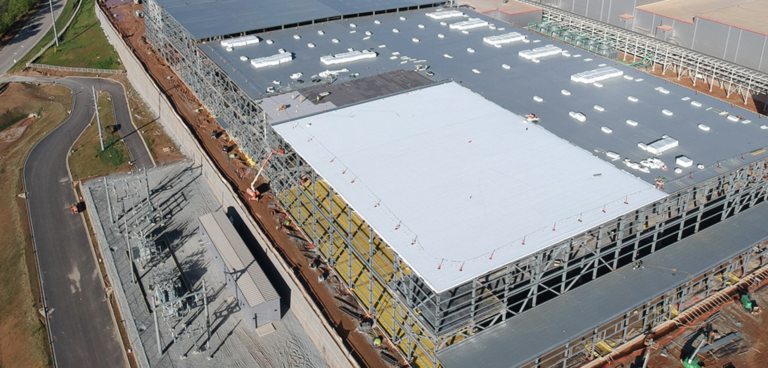

SK Innovation currently has two US-based battery plants in Georgia with an annual capacity of 22GWh. Plant 1, a 10GWh plant (pictured above), currently runs pilot production after mechanical construction was completed earlier this year, with commercial production planned to start in early 2022. Plant 2, a 12GWh facility, is presently under construction with a completion date also set for early next year. In 2023, mass production is expected to begin at the site.