Hofer Powertrain has successfully patented its new Form Litz Wire winding technology. The company states that the new technology – which aims to allow electric motors to be smaller and lighter while maintaining the same high performance as pull-in and hairpin units – will offer significant economic, efficiency and sustainability benefits.

“Achieving multiple efficiency and sustainability goals in powertrains with our technology makes us particularly proud,” commented Johann Paul, CEO at Hofer Powertrain.

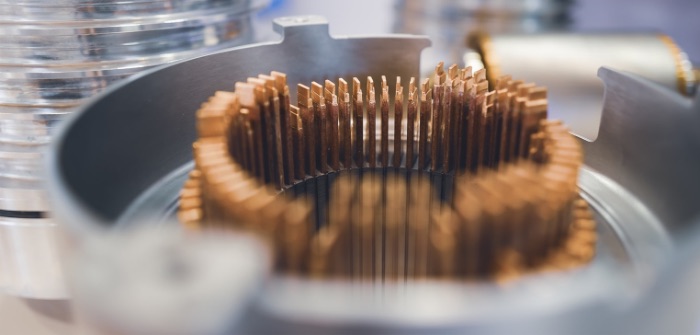

Form Litz Wire consists of parallel wires packed into a highly compact form, ensuring a high filling factor. This enables effective integration with various cooling systems, and a reduction in energy losses by up to 25%. In addition, the quantity of copper, iron and rare earth metals in this permanent synchronous motor (PSM) is substantially lower.

The Hofer winding technology is designed to be cost efficient, with the Form Litz Wire’s robust design lending itself to consistent production quality and scope for automation. This means that in the near-term, manufacturers will be able to use conventional hairpin winding tools to achieve production. The company is now directing its efforts toward large-scale production to increase the economic benefits even further.