Hyundai Motor Group has released details of its new Electric-Global Modular Platform (E-GMP), a dedicated battery electric vehicle platform which it says will serve as the core technology for its next-generation BEV line-up. From 2021, the E-GMP will underpin a range of dedicated new BEVs, including Hyundai’s Ioniq 5, Kia Motors Corporation’s first dedicated BEV to be revealed in 2021, and a series of other models.

The company says the E-GMP provides various advantages compared with its existing platforms, which have previously been engineered primarily to accommodate internal combustion engines. These include increased development flexibility, greater driving performance, increased driving range, improved safety features and more interior space for occupants and luggage.

“Today our front-wheel driven Hyundai and Kia BEVs are already among the most efficient ones in their segments,” said Albert Biermann, president and head of R&D Division for Hyundai Motor Group. “With our rear-wheel-driven-based E-GMP, we are extending our technological leadership into segments where customers demand excellent driving dynamics and outstanding efficiency.”

“E-GMP is the culmination of years of research and development and brings together our most cutting-edge technologies. Our BEV line-up will evolve and be strengthened by this innovative new platform,” added Fayez Abdul Rahman, senior vice president of Vehicle Architecture Development Center for Hyundai Motor Group.

Hyundai notes that the new platform reduces complexity through modularization and standardization, allowing rapid and flexible development of products which can be used across most vehicle segments, such as sedans, SUVs and CUVs. Moreover, it states that flexible development can satisfy various customer desires related to vehicle performance.

Hyundai notes that the new platform reduces complexity through modularization and standardization, allowing rapid and flexible development of products which can be used across most vehicle segments, such as sedans, SUVs and CUVs. Moreover, it states that flexible development can satisfy various customer desires related to vehicle performance.

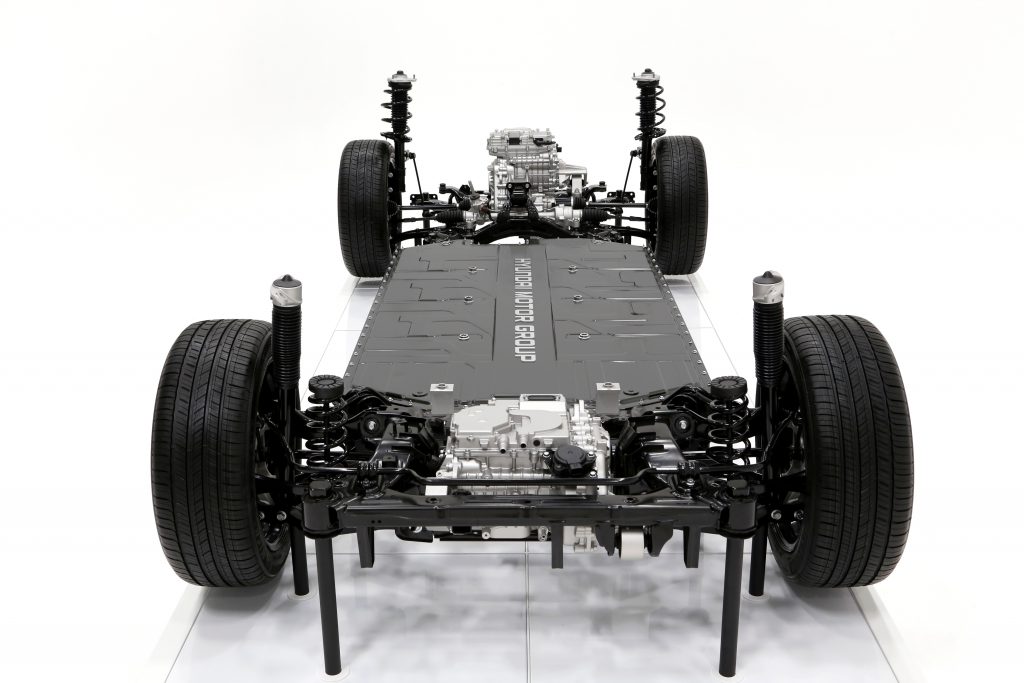

Thanks to an optimal weight distribution between front and rear, Hyundai says the design provides a low center of gravity due to its low-mounted battery pack, and the placement of the electric motors located in the space previously occupied by an engine. It also features a battery support structure made of high-strength steel with hot-stamped steel components surrounding the battery to further increase rigidity.

The battery pack itself – mounted between the front and rear wheel axles – will be the most power-dense system that Hyundai Motor Group has ever created. This, the company notes, is partly thanks to enhanced cooling performance, a result of a new separate cooling block structure which helps make the battery pack more compact and sees energy density enhanced by around 10% compared with existing EV battery technology.

All vehicles developed with the E-GMP platform will use a standardized single type of battery module. This module is composed of pouch-type standard cells and can be packed in different quantities as required for each vehicle. It will also be able to utilize both 800V and 400V charging systems.

All vehicles developed with the E-GMP platform will use a standardized single type of battery module. This module is composed of pouch-type standard cells and can be packed in different quantities as required for each vehicle. It will also be able to utilize both 800V and 400V charging systems.

The electric motor, inverter and transmission are integrated into a single module, with Hyundai having developed a motor running at a claimed 70% higher speed compared with existing automotive units. This is coupled to an inverter incorporating SiC semiconductors, further increasing efficiency. The E-GMP will be primarily rear-wheel-drive, but the option of all-wheel-drive will be available.