A strategic partnership has been formed between Jaguar Land Rover (JLR) and Wolfspeed which will see the latter company supplying its silicon carbide semiconductors for JLR’s next-generation electric vehicles (EVs).

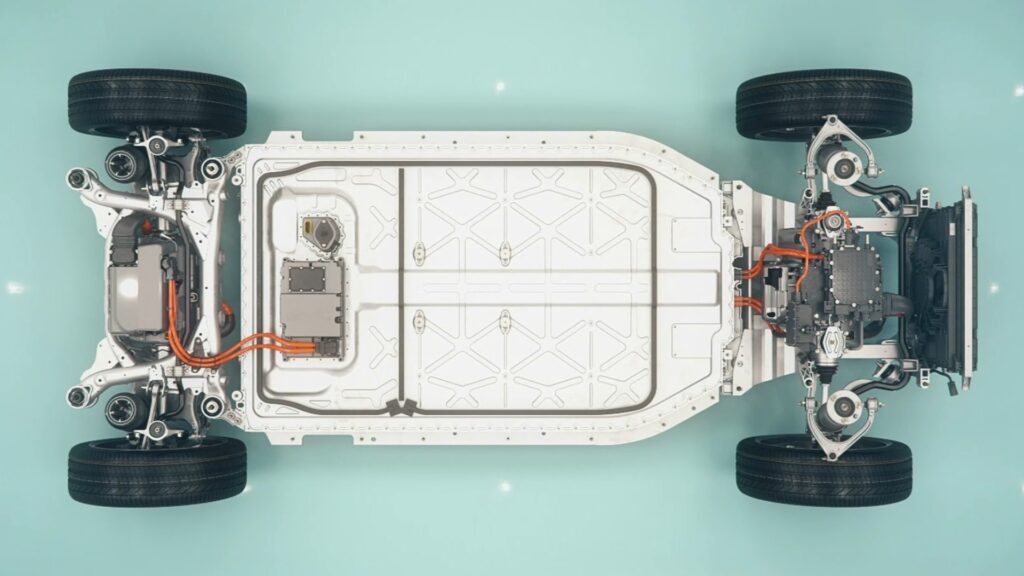

JLR will use Wolfspeed’s advanced silicon carbide technology within its vehicles’ inverters to manage the transfer of power from the battery to the electric motors. The technology will first be used in Range Rover models in 2024, and all-electric Jaguar models in 2025. Wolfspeed’s solution is said to deliver increased powertrain efficiency and extended driving range.

As part of the agreement, Jaguar Land Rover will participate in the Wolfspeed Assurance of Supply Program to secure the technology supply for future EV production. This will also ensure and enable greater visibility and control over JLR’s future supply chain.

The silicon carbide power device solutions will be manufactured at Wolfspeed’s fully automated Mohawk Valley Fab located in Marcy, New York.

“We are not strangers, having collaborated together with the Jaguar TCS Racing team for the last five seasons,” said Thierry Bolloré, chief executive officer, Jaguar Land Rover. “By developing that into a strategic partnership as part of our Reimagine strategy, we can integrate Wolfspeed’s advanced silicon carbide technology into our next generation electric vehicles, delivering extended range and performance capabilities for our clients.”

“Wolfspeed is proud to partner with Jaguar Land Rover, supporting its bold commitment to electrify its iconic brands by using Silicon Carbide’s superior performance, efficiency and range,” added Wolfspeed president and CEO Gregg Lowe. “The energy efficiency of silicon carbide will play an essential role as Jaguar Land Rover pursues its own zero carbon goals, and as the world transitions to an all-electric transportation future.”

The newly announced partnership builds on Wolfspeed’s existing relationship with the Jaguar TCS Racing team which competes within the ABB FIA Formula E World Championship. The silicon carbide technology has already been used on the team’s car to increase on-track efficiency and performance.