Specialty chemical company Evonik has released details of its newly developed Pure Performance Battery (PPB), which was developed through the Vestaro consortium alongside partners including composite structures specialist Forward Engineering and Tier 1 automotive supplier Minth.

Based on Sheet Molding Compound (SMC) technology which uses Evonik’s curing agents, the battery system concept provides the automotive industry with a safe, lightweight and, most importantly, cost-effective alternative to the traditional heavier metal-based solutions, the company says.

Formed at the end of 2019 to investigate alternative battery solutions, Vestaro initially developed a cost-effective glass fiber-SMC battery pack cover based on Evonik’s epoxy curing agent Vestalite S. In addition to reducing the weight of the battery housing by almost 10% compared to similar covers made from more cost-prohibitive materials, the SMC materials also performed in a comparable way to previous metal-based enclosures while giving greater design freedom.

Minth joined the consortium in 2021 bringing with it in-depth know-how relating to aluminum solutions, enabling the group to tackle two major challenges facing current battery packs: the bottom impact use case and vehicle integration.

To meet stringent OEM requirements in terms of side pole, and bottom impact tests without any leakage or failure, the consortium came up with an approach that fully utilized the design freedom of the SMC material. The old bottom structure was replaced with an aluminum sandwich plate developed by Minth, which increases the performance in terms of the bottom impact, but also made the pack a semi-structural element of the vehicle chassis. With this concept the consortium was also able to remove the additional side deformation elements and use the freed space for more battery cells instead.

Additionally, due to the improved bottom impact performance of the sandwich floor, the space required for the module mounting could be reduced. The creation of this extra space for battery cells led to an overall capacity increase of 10kWh, from 65kWh to 75kWh, with comparable battery pack outer dimensions to the consortium’s previous generation.

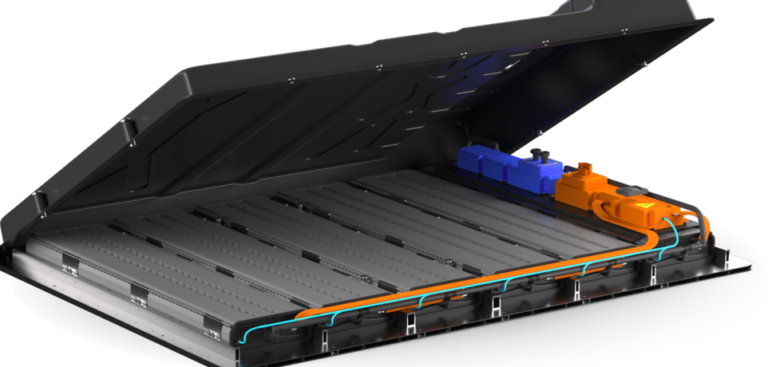

Designed and validated using Forward Engineering’s BEV-floor structure development tool, the PPB is around 2.1m long and 1.58m wide with maximum heights of 0.15-0.22m, and is said to be suitable for a variety of vehicle architectures.

Furthermore, the battery’s semi-integral modular design enables flexibility in the number of modules used. It uses a ‘supercell’ concept based on supplier Lion Smart’s Light Battery which enables a calculated fast charging result of around 13 minutes with charging power constantly above 200kW (10%-80% SOC). The system is currently being developed with the aim of achieving charging times of less than 10 minutes.

[ends]