With its new Artura supercar, McLaren has embraced hybridization and, for the first time in one of its road cars, a V6 rather than V8 engine layout.

“The McLaren Artura’s all-new, super-lightweight electrified powertrain is at the cutting-edge of high-performance hybrid technology, engineered to offer all of the advantages of internal combustion and electric power in one package and establish new benchmarks for combined performance and efficiency in the supercar class,” explained Geoff Grose, chief engineer at McLaren Automotive, adding, “The ‘clean-sheet’ design of the Artura has allowed us to focus on how to make this power accessible to the driver and deliver the levels of engagement expected from a McLaren.”

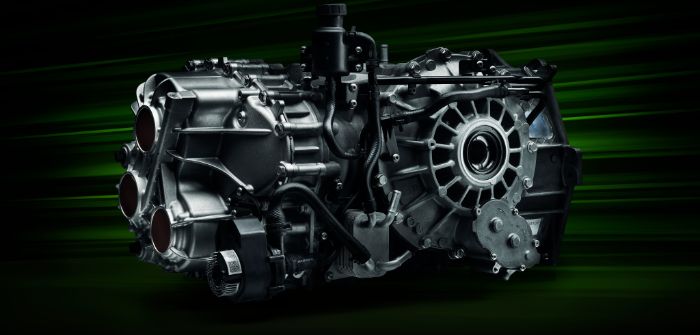

The twin-turbocharged 3.0-liter V6 internal combustion engine, designated the M630, uses a 120° vee angle. According to McLaren, a 180° bank angle was considered but dismissed because it would raise the height of the crankshaft and therefore the center of gravity of the car.

McLaren notes that the wide angle of the V6 cylinders allows the turbochargers to sit within the banks in a ‘hot vee’ configuration, which also benefits efficiency as they sit within a straighter – and therefore less restrictive – exhaust layout. Generating 585PS and 585Nm of torque, the engine is 190mm shorter and 220mm narrower than McLaren’s twin-turbo 4.0-liter V8, and also 50kg lighter.

Although the configuration of the engine is key to the Artura’s powertrain packaging, McLaren notes that it has harnessed some of the latest manufacturing techniques to reduce weight and improve performance. For example, the cylinder head and block utilize 3D-printed cores, allowing for improved heat transfer thanks to the inclusion of a 2mm cooling passage between the cylinders. The block also has directly coated bores rather than separate coated liners. For the rotating assembly, shared crank pins enable a very short and stiff crankshaft that allows the M630 to redline at 8,500rpm. The ancillary drives are situated at the rear of the engine to reduce cabin noise.

Although the configuration of the engine is key to the Artura’s powertrain packaging, McLaren notes that it has harnessed some of the latest manufacturing techniques to reduce weight and improve performance. For example, the cylinder head and block utilize 3D-printed cores, allowing for improved heat transfer thanks to the inclusion of a 2mm cooling passage between the cylinders. The block also has directly coated bores rather than separate coated liners. For the rotating assembly, shared crank pins enable a very short and stiff crankshaft that allows the M630 to redline at 8,500rpm. The ancillary drives are situated at the rear of the engine to reduce cabin noise.

Power is transferred to the rear wheels via a new eight-speed seamless shift transmission that has also been designed with packaging in mind. To this end, the length of the gear cluster has been reduced by 40mm (compared with the V8 transmission), helped by use of a nested clutch rather than a parallel unit and also the removal of a reverse gear, this function now achieved by the Artura’s e-motor spinning in the opposite direction. This motor is fully integrated within the transmission bell-housing, delivering torque in-fill and linear acceleration via an e-differential to the rear wheels.

The hybrid motor itself is an axial flux unit, which weighs in at 15.4kg and can generate 94bhp and 225Nm of torque. This is coupled to a 7.4kWh, five-module lithium-ion battery pack, which is incorporated into the Artura’s McLaren Lightweight Architecture (MCLA) chassis, positioned low down in the car behind the driver, incorporated into the floor and protected on three sides by the main carbon-fiber structure and from behind by the engine. This positioning helps to optimize center of gravity and the polar moment of inertia, benefitting dynamic agility.

The battery sits on a cooling manifold, which is shared with the new electric heating, ventilation and air-conditioning system also used to control air temperature in the cabin. Incorporating technology first developed for the McLaren Speedtail, the batteries are thermally controlled using dielectric oil – a technology also used to keep the e-motor at operating temperatures that deliver the highest level of performance.

The battery management unit sits alongside the modules, with the power distribution unit (PDU) integrated into the battery. An integrated power unit (IPU) acts as a DC-DC converter for the vehicle’s 12V system, further reducing weight by removing the need for a separate alternator and onboard battery charger.