Mercedes-AMG has revealed its new drive strategy as the German brand looks to combine performance and driving dynamics with maximum efficiency. The plan is to offer hybrids with a completely independent drive concept under the technology label E Performance, as well as battery-electric AMG derivatives based on Mercedes’ Electric Vehicle Architecture (EVA).

“With our new drive strategy, we are transporting our hallmark DNA into an electrified future,” explained Philipp Schiemer, chairman of the board of management, Mercedes-AMG. “Our performance hybrids, developed entirely in Affalterbach, will even surpass the driving dynamics of our current models and thus absolutely do justice to our new technology label E Performance. With the all-electric derivatives based on the Mercedes-EQ models, we as Mercedes-AMG are also continuing to take off with the electrification of the portfolio.”

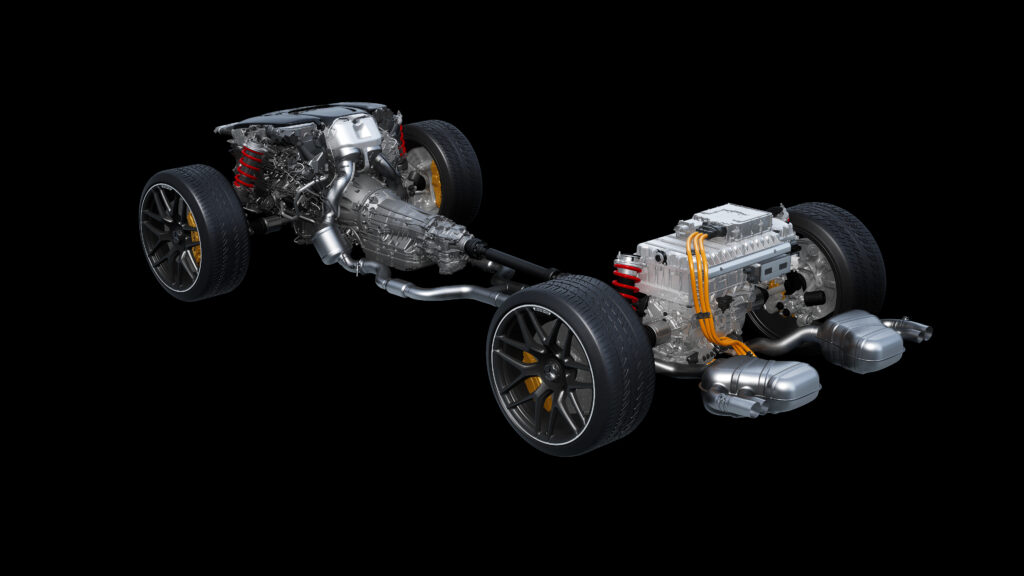

The independent E Performance drivetrain strategy is based on the principle of developing an electrified drivetrain that further enhances the brand’s signature driving dynamics, while also being highly efficient. As a performance hybrid, the modular AMG concept combines an eight- or four-cylinder engine with a permanently excited synchronous electric motor, a high-performance battery and fully variable 4MATIC+ all-wheel drive.

The electric motor is positioned on the rear axle, where it is integrated with an electrically shifted 2-speed transmission and the electronically controlled rear axle differential lock in a compact electric drive unit (EDU) – a P3 hybrid layout. The lightweight battery is located above the rear axle.

At the heart of this is AMG’s High Performance Battery (HPB). Development of the lithium-ion energy storage system began in 2016 and was inspired by Formula 1 technologies. The aim for the HPB is to combine frequent and sequential access to high power with low weight. Added to this is fast energy absorption.

The basis for the high performance of the AMG 400V battery is direct cooling. For the first time, all 560 cells are cooled individually, permanently surrounded by a high-tech coolant based on an electrically non-conductive liquid. For the direct cooling, specialists had to develop new cooling modules that are only millimeters thin.

Parallel to the development of the eight-cylinder performance hybrids, AMG is also combining its performance hybrid system with the M 139 four-cylinder turbo engine. The 2.0-liter unit has so far been used transversely, but in E Performance application it will sit longitudinally. The OEM is also thoroughly reworking the M 139 and is aiming to once again surpass its record for the world’s highest output of all four-cylinder series engines.

Parallel to the development of the eight-cylinder performance hybrids, AMG is also combining its performance hybrid system with the M 139 four-cylinder turbo engine. The 2.0-liter unit has so far been used transversely, but in E Performance application it will sit longitudinally. The OEM is also thoroughly reworking the M 139 and is aiming to once again surpass its record for the world’s highest output of all four-cylinder series engines.

Key to the updated hybrid M 139, which will debut in the next-gen C-Class, is an electric exhaust-gas turbocharger. The electric exhaust-gas turbo solves the conflict of objectives between a small, fast-responding turbocharger, which achieves low peak power, and a large turbocharger with high peak power, which in turn responds with a significant delay.

This is thanks to integration of a smaller e-motor directly on the shaft of the exhaust-gas turbocharger, between the turbine wheel on the exhaust gas side and the compressor wheel on the fresh air side. Electronically controlled, this directly drives the shaft of the exhaust-gas turbocharger and thus accelerates the compressor wheel before the exhaust gas flow takes over the drive.

The result is an engine that responds significantly faster to accelerator pedal input. In addition, turbo electrification enables higher torque at low engine speeds. Even when the driver takes their foot off the accelerator or applies the brakes, the e-turbo technology is able to maintain the boost pressure at all times to ensure continuous direct response.

The turbocharger is operated with the 400V onboard power supply and thus achieves speeds of up to 156,000rpm, which allows high air flow. The supercharger and electric motor are connected to the high-temperature cooling circuit of the combustion engine to create the best possible temperature environment at all times. The power electronics are cooled via the low-temperature circuit.

In addition, Mercedes-AMG is also developing performance vehicles with all-battery-electric drive. The first battery-electric AMG models will be based on the Mercedes-EQ architecture, and the vehicles’ drive, chassis, brakes and sound will be extensively redeveloped in Affalterbach specifically for each market.

The new performance models will launch with two independent, permanently excited synchronous machines and fully variable all-wheel drive with modular torque distribution. AMG is claiming that the preliminary performance values of the test vehicles are already very promising with performance on a par with the most powerful current 4.0-liter V8 biturbo engine.

The electric motors rev up to a maximum of 18,000rpm and enable a top speed of up to 250km/h, while the 400V lithium-ion battery receives its own wiring harness, which is adapted to the higher performance capacity of the AMG derivatives. Added to this is an AMG i-Booster function, which combines electric recuperation and hydraulic braking during deceleration.