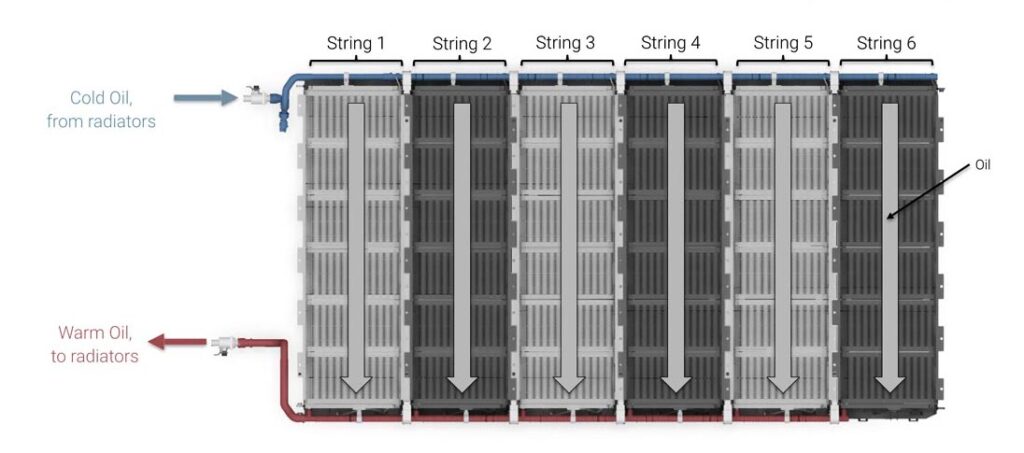

M&I Materials, the company behind the MIVOLT DF7 ester dielectric fluid planned for use in the Faraday Future FF 91’s immersed battery solution, is working with ‘numerous OEMs’ on immersion projects, raising the prospect of wider applications for the innovative battery cooling concept.

In response to an inquiry from E+PTI, M&I confirmed that work continues with the unnamed OEMs to apply the non-toxic, biodegradable fluid to immersion cooling developments, as well as deploying it on Innovate UK’s new electric urban air propulsion project and the University of Warwick’s Warwick Moto superbike.

“MIVOLT has been found to be compatible with all battery external materials that have been tested so far,” said MIVOLT product engineer, Eleanor Jones. “As part of our i-CoBat project we have tested several common internal battery materials and found no adverse reactions.”

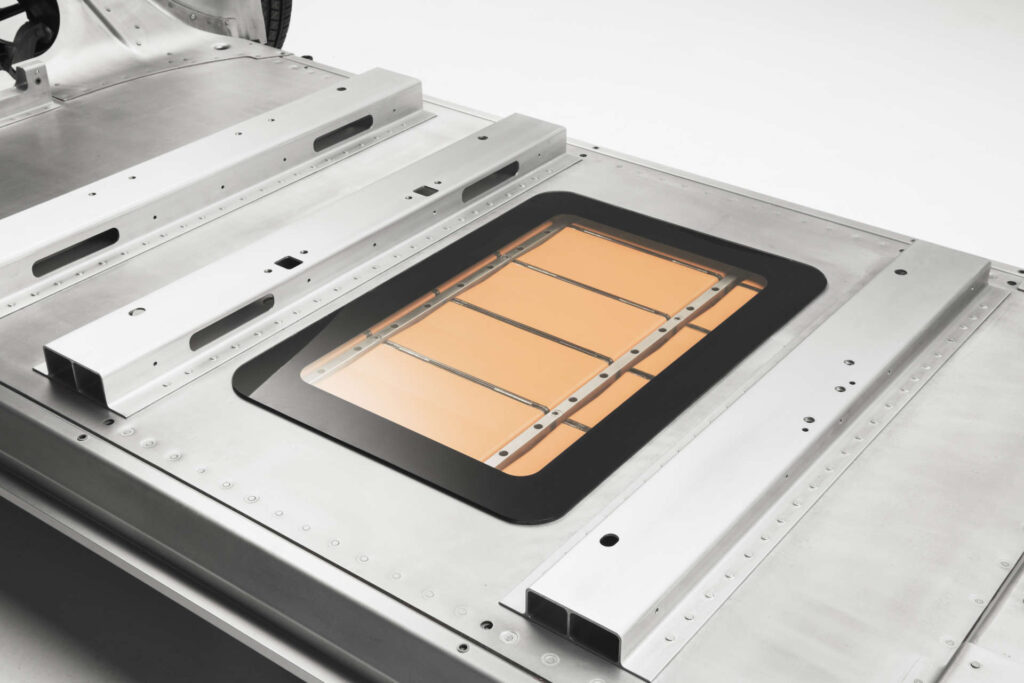

The Faraday Challenge i-CoBat project to validate the concept of immersion cooling for vehicle batteries was funded by Innovate UK and concluded in February 2021. According to M&I, other findings showed that immersive cooling could help suppress thermal runaway in cells and deliver a 43% increase in charge rate versus conventional, cold-plate cooling technology.

A further finding of i-CoBat was that the overall pack size and weight were reduced, even though the coolant weight is higher, bringing the advantage of an overall increase in the pack energy density and power density.

“The work we’ve done in the i-CoBat shows as well that you can significantly reduce the thickness of things like the bus bars if you cool them,” added M&I’s technical lead for research and development in next-generation advanced materials, Mark Lashbrook. “You can strip out quite a lot of weight in that way.”

Meanwhile, work continues to ready the FF 91 luxury EV for production, which is scheduled to start within 12 months of the conclusion of FF’s merger with Property Solutions Acquisition Corp (PSAC). That deal is set to be confirmed by the end of Q2 2021.

The FF 91 recently completed its second season of winter testing and validation in conjunction with Bosch in Baudette, Minnesota and Flat Rock, Michigan. The company’s first EV features a 130kWh battery with a fast charge rate of 800km of range per hour and sub-2.4-second acceleration from 0-97km/h.

As part of a range of new B2B ventures, FF is also making its IP around submerged pack cooling available for licensing.