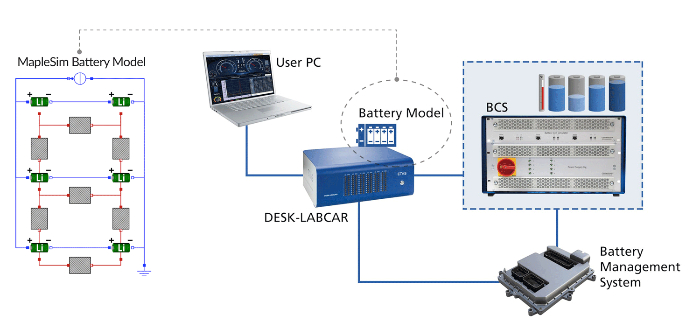

ETAS and Maplesoft have released a revolutionary HIL battery cell simulator package for the test and calibration of battery management systems. The solution is based on Maplesoft’s MapleSim battery model and ETAS’ high-precision battery cell simulator, BCS-LABCAR.

BCS-LABCAR enables signal-level test, validation, and calibration of battery management systems. It emulates the behavior of individual battery cells and packs across a wide range of challenging operating conditions, e.g. cell balancing over-charging, deep discharging, or pulse operation.

The system is highly modular and thus scalable to emulate battery packs from a single cell all the way up to 200 cells. Furthermore, the system contains a real-time simulation target, which enables the easy integration of third-party battery models – such as the MapleSim battery model – and their execution in real-time.

The MapleSim battery model can be generated from an extensive range of cell configurations and chemistries using the MapleSim battery library. Developed using a unique, rigorous discretization approach, the library components model the electro-chemical reactions in the cell to capture many details that are unavailable in other battery models, which are typically based on an equivalent circuit approach. All the major chemistries (based on li-ion and NiMH variants) are provided, and can be readily calibrated from test data using the parameter estimation tool for added accuracy.

Once configured in MapleSim, the cell/stack/battery model can be exported as optimized code and readily integrated into the real-time platform for HIL testing. In this case, the code was deployed using the latest FMI standard, now supported by the ETAS LABCAR-RTPC platform.