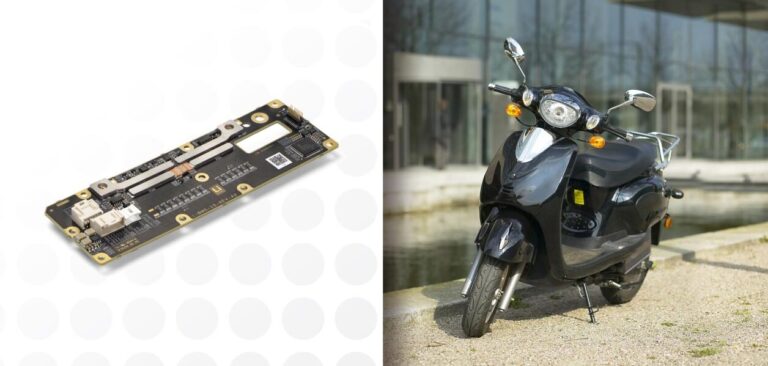

Sensor specialist Sensata Technologies has announced the availability of its new i-BMS battery management system (BMS) for electrified applications up to 60V. The system, developed under Sensata’s Lithium Balance product brand (acquired by Sensata earlier in the year), is a cell chemistry-agnostic, compact, integrated BMS developed for the cost-optimized mass-production of applications up to 60V, such as 2-, and 3-wheelers, automated guided vehicles (AGVs), and robotics.

According to the company, hot swap functionality and parallel battery pack support create the ability to quickly exchange depleted batteries with fully charged units. This function makes it ideal for use in applications such as material handling vehicles, delivery vehicles and drones. For electric motorbikes and three wheelers, instead of needing to recharge for several hours every evening, fully charged batteries can be rapidly installed in the field at battery swap stations, practically eliminating the need to wait and charge on the road.

Parallel pack support allows the use of two or more battery packs in parallel. This functionality allows OEMs of 2- and 3-wheelers to have smaller battery modules, improving the safety and serviceability of the battery system. For example, if one battery cell fails while in use, the issue is isolated to that one faulty module which is easier to replace than the entire system and additional battery packs can continue to provide power.

Measuring 65 x 200mm, the i-BMS PCB board is equipped with everything required to manage and maintain a battery system without the need for any external components. All critical components are integrated into the system, including a pre-charge circuit, onboard current measurement, MOSFET power switches for battery disconnect, and a DC/DC power supply. The solution features key components that are ASIL C Safety rated and include self-test capabilities for safety critical measurement circuits.

Algorithms in the BMS’s software ensure accurate state-of-power (SOP) predictions based on cell internal resistance, voltage and current constraints, precise state-of-charge (SOC) calculations, and SOH (state-of-health) calculated based on aging effect. Furthermore, the company’s BMS Creator configuration software allows the battery pack designer to create a unique battery setup by defining application-specific BMS parameters and safety strategies, optimizing battery operation.

Other software features include measurement of rate of change of temperature to predict thermal runaway, dynamic regulation of current in extreme thermal conditions, as well as advanced parameter settings for CAN communication.