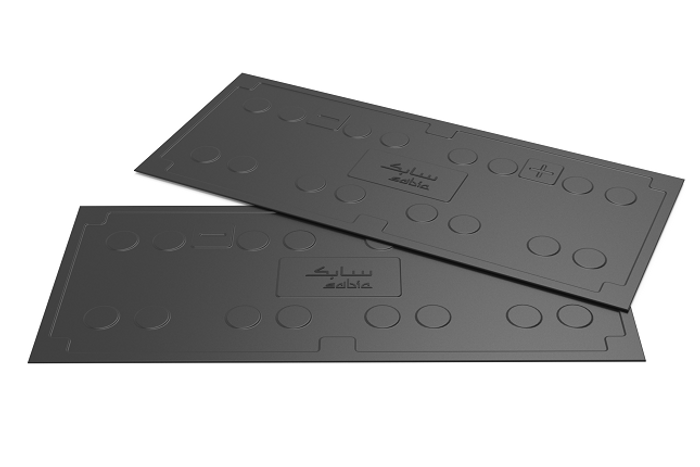

Chemical company SABIC (Saudi Basic Industries Corporation), has released its Noryl NHP8000VT3 resin, a product it says is well suited for insulation film used in electric vehicle (EV) battery modules to help improve protection against short circuits and fire propagation.

The polyphenylene ether (PPO)-based resin is engineered to help meet the stringent demands of higher voltage batteries (600-800V). The company states that it achieves the highest comparative tracking index performance level category (CTI PLC0), provides ultra-thin-wall extrusion and thermoforming capability, and meets the UL94 V0 standard at 0.25mm with non-brominated, non-chlorinated flame retardance. The resin provides a novel solution to the drawbacks of incumbent insulation films made with polycarbonate (PC) and polypropylene (PP) by delivering stronger CTI performance and thinner-wall FR capability. This exceptional material can help advance EV battery technology by contributing to occupant safety, weight reduction and higher efficiency for extended range.

“Transitioning from standard, 400V EV batteries to higher voltages offers the potential to shorten charging times, extend range and improve energy management within the vehicle,” said Joshua Chiaw, director, business management, LNP & Noryl, Specialties, SABIC. “However, designing higher voltage batteries requires the invention of breakthrough materials, such as our new Noryl resin for insulation films. This new solution is the industry’s first thermoformable material to achieve the highest CTI performance level as well as meeting stringent flame retardancy standards. SABIC continues to focus intensively on developing innovative material solutions that can propel e-mobility adoption by addressing safety, performance and range anxiety challenges.”

The CTI PLC, which indicates the maximum voltage a material can withstand without developing tracking, is used to evaluate electrical insulators under exposure to conditions of stress, humidity and contamination. Noryl NHP8000VT3 resin achieved the highest CTI performance level category of 0 in testing by an independent laboratory, indicating it can withstand 600V and greater. While some PP grades can also achieve CTI PLC0, these materials are more difficult to thermoform, often requiring the application of secondary processes to achieve complex shapes. Furthermore, the resin delivers better mechanical strength than PP at 0.25mm thickness. SABIC notes that polycarbonate, the other incumbent battery insulation material, typically cannot achieve CTI PLC0.

The resin’s ability to meet the UL94 V0 standard at 0.25mm means it can provide a high level of flame retardance at a thinner film gauge than PC or PP, potentially freeing up valuable space in the battery pack. Compared to PC, Noryl NHP8000VT3 resin features up to 40% weight reduction due to its lower specific gravity and thinner wall FR capability. This capability can also potentially benefit other EV applications. For example, the new Noryl resin may be a candidate for the insulation of metal EV busbars, using overmolding or insert molding processes.