Schaeffler says it is on the verge of releasing several new EV powertrain systems, covering applications from thermal management to high-voltage power electronics.

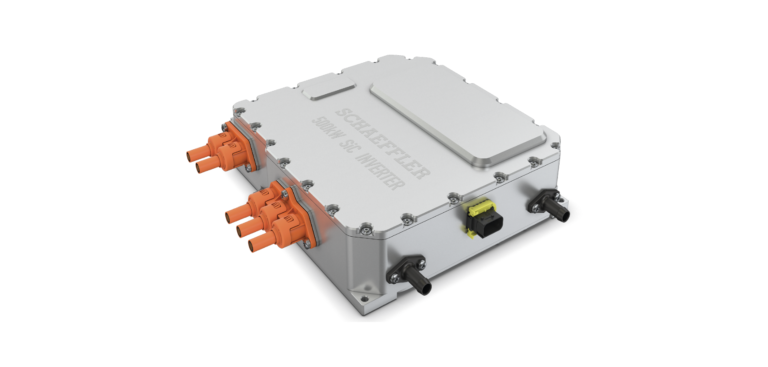

These will include an in-house-developed 800V power electronics system for electric axle applications in high-performance vehicles. The company states that the scalable solution enables continuous outputs of up to 330kW and short-term peak outputs of up to 500kW. The achievable power density of up to 70kW per liter also allows for small housing dimensions and consequent advantages in integration.

Schaeffler has opted to use the latest silicon carbide wide-bandgap technology in the 800V onboard power supply, which will significantly reduce power losses compared with conventional silicon IGBT technology and enable efficiencies of over 99% in defined load ranges.

Furthermore, the charging speeds achievable with the 800V voltage class are considerably higher than those achieved with the 400V voltage class that has been widely used to date. An in-house motor control solution is also used, which enables various modulation processes and variable switching frequencies.

To achieve a high level of efficiency, Schaeffler has also developed a fully integrated thermal management system to continuously regulate the powertrain temperature, particularly of the battery but also of the electric motor, and the power electronics. The system also controls the temperature in the interior of the vehicle.

Notably, the system’s two electric water pumps, the central electronic unit for the pumps and valves, and a refrigeration circuit interface are all integrated into the central control unit for coolants and refrigerants. Compared with conventional, non-integrated systems, this is claimed to reduce the required installation space by up to 60% and, with its hydraulically optimized design, lays the foundation for a high degree of overall system efficiency.