Schaeffler has announced that three manufacturers of compact municipal vehicles such as road sweepers, vans and snowplows are to incorporate its high-efficiency electric wheel hub motors into their production lines in the near future. The fully electrified vehicles will benefit from zero CO2 emissions, leading to improved air quality in urban areas.

“Schaeffler is reinventing the drive systems used in small, lightweight electric utility vehicles in our inner cities,” said Matthias Zink, CEO of automotive technologies at Schaeffler.

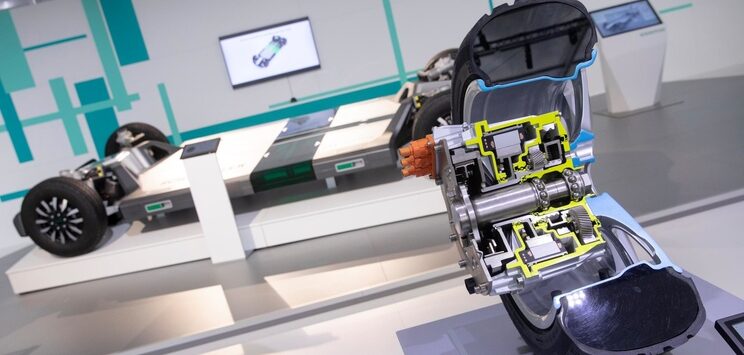

All of the components within the wheel hub motors that are required for propulsion and braking are integrated directly into the wheel rim, resulting in space savings and enhanced handling and maneuverability. Other advantages include quieter operation for less noise pollution.

Jungo has been named as one of the first companies that will be launching a multifunctional vehicle this year using Schaeffler’s wheel hub motor technology. Jungo and Schaeffler have worked collaboratively to ensure the drive technology is optimized for commercial street sweeping.

“The electric in-wheel motors and braking technology eliminate the need for oil changes and greatly enhance our vehicles’ performance in terms of efficiency, power-to-weight ratio, safety, handling and braking reliability,” said Nicolas Jungo, founder and CEO of Jungo.

“In this vehicle segment, as in others, the question is: what’s the fastest and most efficient way to reduce CO2 emissions? And the answer to that question is electrification,” said Dr Jochen Schröder, head of e-mobility at Schaeffler. “This new drive technology opens up a new and steadily growing market for Schaeffler.”

Schaeffler hopes to see its wheel hub motors being used on service vehicles in towns and cities, on factory campuses and at logistics centers, ports, airports and large parking facilities. These vehicles are well suited to the technology as the electric drives lend themselves well to fixed ranges and predictable charging times. Additionally, the wheel hub motors benefit from a long service life and low-maintenance wheel bearings and gearboxes.

The electric motor (stator and rotor), gearbox and mechanical friction brake are situated around the wheel bearing inside the rim. The compact design saves space and also enables vehicle manufacturers to benefit from greater design freedom.

The wheel hub motor – including the gearbox – can fit inside a 14in rim, while the inverter, which is not integrated, can be placed anywhere in the vehicle. A single inverter controls one or two wheel hub motors, depending on the use scenario. The motor’s power output is scalable, depending on the application, ranging from 7kW to 26kW (nominal) and peaking at 60kW for short bursts.

By using a direct transmission, energy loss is reduced, making the drive highly efficient. Another advantage is that torque and direction of rotation are controlled individually for each wheel, resulting in an all-wheel-drive vehicle that can handle hills easily in all weather conditions.