Schaeffler is set to launch several new electric axles. “Electric axles are a key element of our electric mobility strategy,” said Matthias Zink, CEO automotive technologies at Schaeffler.

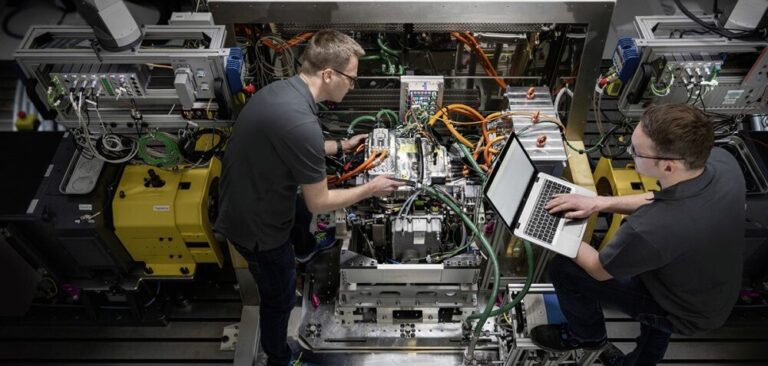

Until now, up to three drive components were assembled together in the company’s e-axles. With its new 4-in-1 electric axle, Schaeffler is now integrating the thermal management system as well as the electric motor, power electronics, and transmission into the axle drive.

The result is a more compact and lighter assembly. The use of a particularly efficient thermal management system also ensures that a car travels further on one battery charge and charges faster. The company notes it is also developing a range of electric beam axles for pickup trucks, which Schaeffler says it will supply to manufacturers, particularly in North America.

“The thermal management system has a significant influence on the efficiency and comfort of the vehicle,” said Dr Jochen Schröder, head of the E-Mobility business division at Schaeffler. Integrating the thermal management system within the axle “creates a highly integrated and compact complete system, which requires significantly less space than non-integrated solutions,” Schröder explained.

Furthermore, less energy is lost in the form of heat because unnecessary hoses and cables can be dispensed with. “In addition to the compact design, the greatest advantage of the 4-in-1 system is the optimized interaction of the individual subsystems,” added Schröder.

An intelligent control system ensures that excess heat is efficiently dissipated from the power electronics and electric motor and that it is used to heat the interior of the vehicle. The system also increases efficiency via the use of a new heat pump, which is operated with carbon dioxide. Not only does carbon dioxide have less impact on the environment than conventional refrigerant, it also has physical characteristics which allow more efficient heating and cooling of vehicles.

An intelligent control system ensures that excess heat is efficiently dissipated from the power electronics and electric motor and that it is used to heat the interior of the vehicle. The system also increases efficiency via the use of a new heat pump, which is operated with carbon dioxide. Not only does carbon dioxide have less impact on the environment than conventional refrigerant, it also has physical characteristics which allow more efficient heating and cooling of vehicles.

“By means of our 4-in-1 electric axle with an integrated thermal management system, we can achieve an even higher efficiency level of the complete system,” noted Schröder. An efficiency level of up to 96% is stated to be possible in an optimally designed system.

“Such highly integrated complete systems are attractive for both established automobile manufacturers and new players,” summed up Schröder. This allows a reduction in the development time and the costs for an entire drive solution.

The company says it will still continue to offer to its customers individual components and subsystems for electric and hybrid drives such as electric motors, transmissions, bearings and the thermal management system.