Vitesco Technologies has secured orders worth more than €2bn (US$1.9bn) for its battery management system (BMS) solution. One of Vitesco Technologies’ significant contracts will deliver a wireless communication version of the battery control units for 400V and 800V BEV architecture.

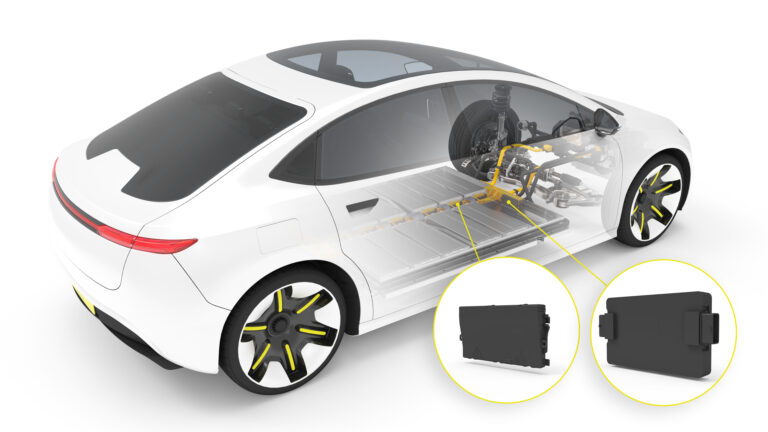

The core functions of the BMS are divided between two types of control units in the Vitesco Technologies portfolio. The first is a battery management controller that permanently monitors the state of cells and modules. It does so via a high voltage sensor that assesses and controls the high current flows toward the battery. In the unlikely event that an undesirable operating condition is detected, it can trigger a corrective action within the battery. In the case of a crash, the BMS also triggers electrical isolation of the battery from the rest of the car. The second is cell supervising circuits that monitor and balance the charging levels of individual battery cells. In Li-ion cells there is always a chance this will occur due to manufacturing tolerances.

“For this purpose, Vitesco Technologies is developing a new procedure for actively balancing cells – hence it is called active cell balancing – which can bring another efficiency gain in the order of several percent,” said Rodrigo Peres, head of product line battery at Vitesco Technologies.

According to the company, its BMS portfolio is designed to facilitate integration into other control units. This would enable a reduction in the number of devices by using fewer control units with much higher computing power and complex software systems.