The Cellforce Group (CFG), a Porsche and Customcells joint venture (JV), has selected BASF to become the exclusive cell development partner for the JV’s next generation lithium-ion battery.

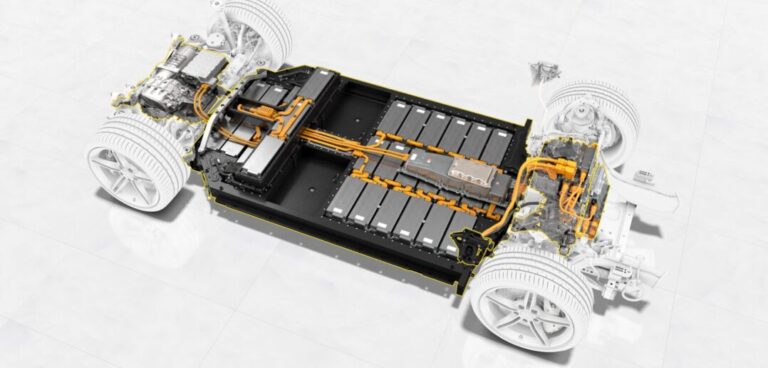

Through a collaborative effort, BASF is to provide CFG with high-energy HED NCM cathode active materials, enabling the production of high-performance battery cells with a high energy density and fast charging attributes.

Based in Tübingen, Germany, CFG will then produce the high-performing battery at the JV’s future battery production plant, with operations estimated to begin in 2024. The collaboration predicts an initial capacity of around 100MWh per year.

BASF says it is positioned to contribute to a circular economy as it benefits from production plants for precursor cathode active materials in Harjavalta, Finland, and for cathode active materials in Schwarzheide, Germany. This enables it to provide battery materials using responsibly sourced raw materials with the aim of achieving the lowest carbon footprint in its supply chain by 2022.

When closing the loop, production waste from the future CFG battery plant will be recycled at BASF’s prototype plant for battery recycling in Schwarzheide. Materials such as lithium, nickel, cobalt and manganese will all be recycled in a hydrometallurgical process and then re-introduced into the production process.

“As an automotive manufacturer, Porsche aims to be CO2 -neutral in its overall balance sheet by 2030. In this respect, a low CO2 footprint, closed-loop recycling and sustainability are increasingly in the foreground,” commented Michael Steiner, member of the executive board for research and development at Porsche.

“The cooperation with BASF is a win-win situation for all parties involved. European sources for the materials nickel and cobalt, the associated security of supply and the short transport routes from Schwarzheide to Baden-Württemberg in Germany were all important arguments for the decision to work with BASF. The battery cells – especially the cathode active materials – are at the center of considerations here.

“We are very pleased that together with BASF we are bringing an environmentally friendly cell technology to series-production readiness.”