According to researchers at the University of Saskatchewan, the use of affordable materials in battery cathodes for high performance applications such as vehicles could soon be viable.

“Cathodes represent 40% of the cost of the batteries that we are using in our phones right now. They are absolutely crucial to improve battery performance and reduce dependency on cobalt,” said Majid Rasool, lead author on a paper (PEDOT Encapsulated and Mechanochemically Engineered Silicate Nanocrystals for High Energy Density Cathodes) that investigates the use of iron and silicon for cathodes.

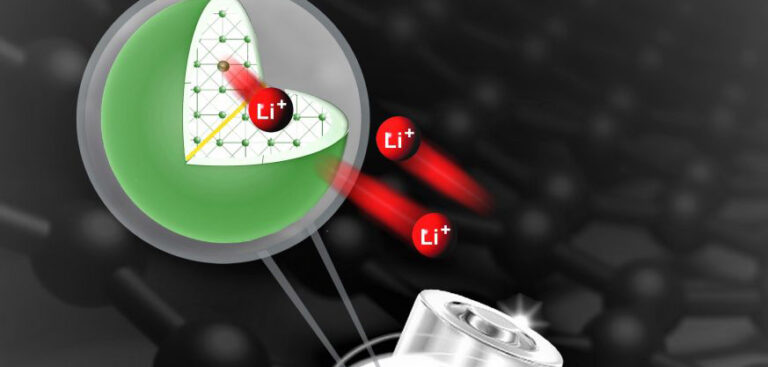

Both iron and silicon are abundant materials, hence why Rasool’s research team wanted to further investigate their potential in battery applications. Lithium iron silicate has a theoretically high-energy capacity, but to date, this has not been realized under real-world conditions.

The group’s breakthrough came thanks to applying an electronically conducting polymer called PEDOT on the surface of cathode nanocrystals through a controlled interfacial reaction. Testing revealed an impressive initial battery capacity as well as improved performance over many charging cycles.

“We were not expecting that big of a jump in performance over [traditional] carbon coating. I knew this could work, but when we got the results, it was really quite fascinating,” said Rasool. Encapsulating nanocrystals in PEDOT was technically difficult to achieve, taking nearly two years of effort, but resulted in what Rasool called “remarkable enhancements” to performance, both in terms of initial and long-term capacity.

The Canadian Light Source (CLS) facility, which houses a synchrotron light source, located at the university, was used to further investigate the underlying reasons behind the encouraging experimental results. Specifically, the researchers used the SM (soft x-ray spectromicroscopy) and Canadian Macromolecular Crystallography Facility beamlines.

Rasool noted, “The CLS was very helpful to let us dig deeper and begin to explain why the PEDOT coating treatment and the sub-surface iron-rich layer improved performance so much.”

Though still very much at the experimental stage, Rasool stated, “There’s still work to be done to understand why and build on this, but this coating process opens up new engineering strategies for batteries.”

Meanwhile, in Germany, battery producer Varta has received funding from the European Commission under its IPCEI (Important Projects of Common European Interest) initiative to further the transfer of technology used in small format, high-energy-density lithium-ion batteries for use in larger formats.

These new battery formats are to be optimized on a pilot line and transferred to mass production. Varta is also continuing to invest in research and development activities for battery cells in special formats, which are increasingly in demand for IOT applications, for example.