Automotive supplier Eaton has detailed its new Internal Exhaust Gas Recirculation (iEGR) technology.

The company says the development will enable auto makers to meet stringent regulations on diesel engine emissions by providing direct control over the thermal management of the exhaust system.

Diesel exhaust leaves the engine following combustion with pollutants nitrogen oxides (NOx) and particulate matter (PM). The particulate matter is then trapped in a diesel particulate filter (DPF) and diesel exhaust fluid is sprayed into the exhaust, where it hydrolyzes into ammonia (NH3).

From there, ammonia and nitrogen oxides travel to a selective catalytic reduction (SCR) system where a reaction turns them into harmless nitrogen and water. In order for the reaction to occur, however, temperatures of 250-500°C are needed.

EGR is used to generate hotter exhaust gas, and therefore heat the catalyst to the proper operating temperature, by slightly opening one exhaust valve during the piston’s intake stroke to draw hot exhaust gas directly from the exhaust manifold into the cylinder.

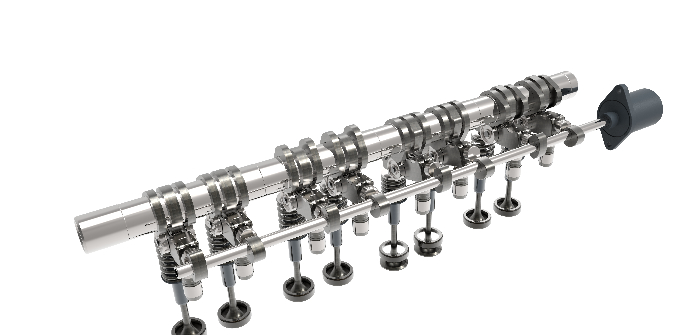

Eaton’s iEGR technology uses a switchable roller rocker arm on each cylinder that can be electro-mechanically actuated.

Systems that rely on hydraulic pressure to provide EGR functionality take longer to generate heat, whereas the Eaton developed system is claimed to provide the needed heat nearly instantaneously, helping to eliminate emissions during cold starts.