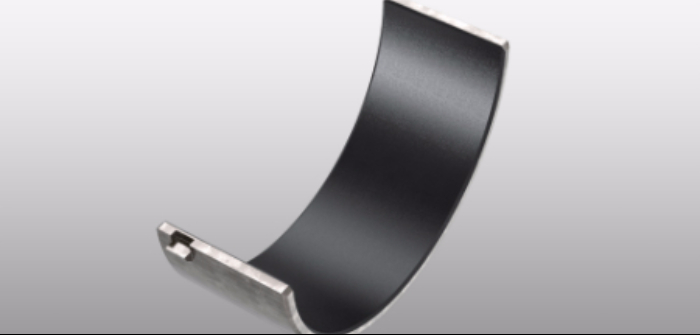

Federal-Mogul Powertrain is extending its crankshaft bearing portfolio with a new high performance polymeric coating, IROX 2, which will debut later this year. The newly developed product provides enhanced seizure performance with steel crankshafts. IROX 2 joins Federal-Mogul’s existing family of IROX technologies which reduce friction and improve the wear resistance and fatigue limit of the bearings used in today’s highly evolved downsized engines.

“IROX was developed for crankshafts with a standard surface finish, whereas IROX 2 is intended for crankshafts with extra smooth finish running with thinner oils,” explained Gian Maria Olivetti, chief technology officer, Federal-Mogul Powertrain. “Compared to aluminium bearing surfaces, both IROX and IROX 2 give reduced friction and greater wear resistance, whereas in comparison to IROX, IROX 2 features further enhanced seizure performance, so we can offer each customer the optimum formulation for their specific application. By reducing friction, the innovative bearing coatings also help to lower fuel consumption and CO2 emissions.”

The bearings have an overlay that is a PAI (Polyamide-imide) polymer resin binder containing a number of additives dispersed throughout the matrix. Developing IROX 2 involved modification of the binder system on a molecular level, coupled with subtle changes to the composition. For example, compared to IROX, IROX 2 contains no silicon carbide particles and has a higher content of a synergistic mixture of solid lubricants.

“IROX bearings are already used by 46 engine families around the world, with over 150 million bearings now in service, contributing to reducing engine friction and improving efficiency while also enabling the use of a lower viscosity oil”, added Stefan Rittmann, director of technology, bearings, Federal-Mogul Powertrain. “Rigorous testing throughout the engine speed range shows the reduction in friction when using IROX-coated bearings is bigger than that obtained by changing from 5W30 to 0W20 oil.”

During the development of IROX 2, Federal-Mogul Powertrain used specialised test rigs, many of which were developed in-house, such as a special bearing friction rig that tests actual bearings, not just flat material samples. It can take the bearing through a complete sweep of shaft speeds in a single seamless test cycle, allowing the comprehensive study of frictional behaviour under boundary, mixed and full fluid film lubrication, with precise control. Other tests included: seizure resistance, using a motored single cylinder test rig applying an actual con-rod and piston; conformability, run under cycling load with a tilted con-rod; as well as wear and fatigue.

The new polymer coated high-performance bearings can be applied to both light and heavy-duty engines, and are particularly effective in hybrid and start/stop applications that place additional demands on bearings through frequent re-starting.