Tier 1 supplier Federal-Mogul will launch a new smaller version of its Rotocap valve rotator at the Frankfurt motor show (IAA) next month.

The company’s first valve rotator designed for four valve per cylinder light vehicle engines, features an outer diameter in the range of 20-25mm. This means that the newest addition to the Rotocap line-up will package seamlessly into powertrain valve assembly.

The Tier 1 supplier claims that the mini rotator will offer lower emissions and greater fuel efficiency. This is thanks to extensive development on the Rotocap, which means it will counteract reduced valvetrain lubrication and engine downspeeding.

Chief technology officer for the US company, Gian Maria Olivetti, spoke about offering more components for light vehicles: “The design function of Rotocap has already been proven in the heavy-duty sector, where engines often run too slowly to generate consistent valve operation.

“We can now apply the technology to light vehicles, where downspeeding trends and increasing urban traffic density require engines to operate for prolonged periods at low speeds, which requires forced valve rotation.”

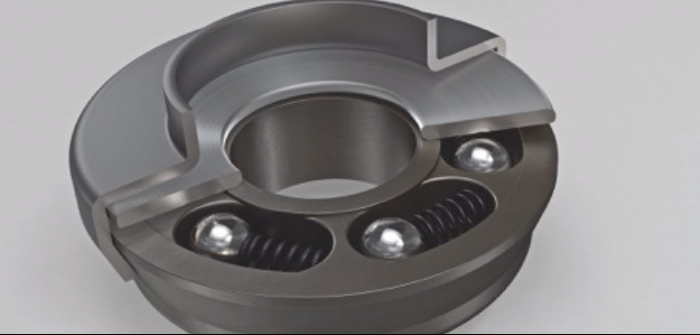

Federal-Mogul has used an innovative design to reduce the valve rotators size, with a compact arrangement of balls and ramps housed within a self-contained assembly. This means that the Rotocap design aims to eliminate uncontrolled rotation which can be transferred to the valve during opening and closing.

The Tier 1 supplier has combatted this through controlling the motion through a defined angular movement that only takes place when opening the valve.

This enhanced rotation control results in an even distribution of temperature around the seat, reducing wear on direct components, local distortion, and preventing cracks on the sealing surface.

In a further development Olivetti revealed plans to target the expanding hybrid market as the Tier 1 supplier moves forward: “Hybrid applications operating on a limited RPM range will benefit from this technology.”