The Mahle Shifting Roller System can adapt to engine operating conditions by managing exhaust gas temperature and providing engine braking to reduce operating costs of commercial vehicles.

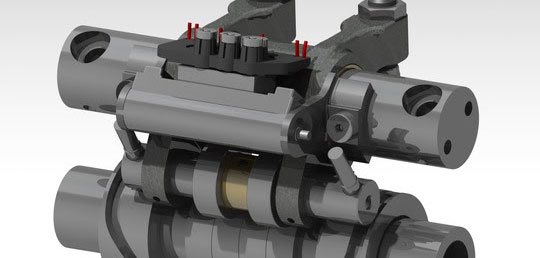

The system uses an adjustable cam follower which can be brought in contact with either one of the two differently profiled cam lobes. Depending on the lift curve of the second cam lobe, the engine can be operated as a permanent brake, for exhaust gas temperature management, or for use with Miller cycles.

Mahle claims that its system considerably reduces moving masses compared to adjustable cam segments on the camshaft, resulting in lower actuating forces and reduced installation space.

The system is also electrically actuated for additional reliability, since electric systems are not influenced by engine temperature and can facilitate selective cylinder activation, switching between operating states quickly and cleanly.

When used as an engine brake, the Mahle Shifting Roller System achieves a braking effect close to a retarder, thanks to its two-stroke mode. The company also promises a performance advantage in comparison with hydraulically actuated systems.

The braking effect of the system is approximately the same as the engine output. Furthermore, no additional components or systems are required for the engine brake. As the cylinders can be activated individually, the engine brake can be actuated gradually and adapted to the current brake power requirements.

When used to control cylinder temperatures, the system can open the exhaust valves sooner to allow the exhaust gas temperature to be increased while keeping fuel consumption low. Exhaust gas with a higher enthalpy enables earlier SCR catalyst light-off or regeneration of the particulate filter under partial-load operation.

Finally, the Shifting Roller System can close the intake valves earlier or later to reduce the effective compression ratio, lowering combustion temperature and pressure and transferring part of the compression work to the turbocharger.