Mahle Powertrain has revealed that the latest iteration of its Jet Ignition system can be integrated into existing engine designs with only minimal changes to the final machining process. According to the company, continued work throughout the lockdown period means that passive MJI can now be installed as a press-in unit into engines utilizing an M12 sparkplug, or larger.

“As the automotive industry seeks ways to unlock incremental efficiency and performance benefits from the internal combustion engine, jet – or pre-chamber – ignition technology is rising to the fore,” explained the company’s head of new technology and data management, Adrian Cooper. “We are beginning to see jet ignition being adopted into high-end production powertrains, such as Maserati’s recent Nettuno V6.”

Mahle has been developing its novel MJI pre-chamber ignition technology for over a decade, and the company notes it can be used as either a passive or active system, suitable for use with either port or direct fuel injection systems.

“We have worked with manufacturers and pinnacle motorsport such as F1 on the integration of this technology for close to 10 years,” added Cooper. “However, our recent work on passive MJI makes the technology more accessible for adoption by mass-produced engines even as a retro-fit to existing designs, as part of a highly efficient powertrain.”

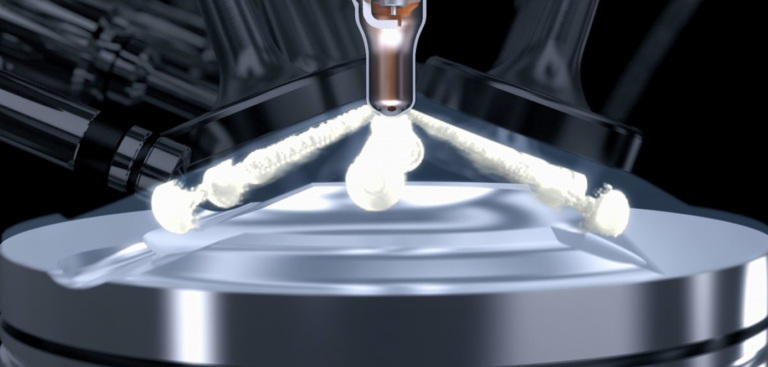

The passive MJI system features a small pre-chamber, which when ignited discharges extremely fast-moving, heated jets through a series of nozzles. This provides multiple ignition sites within the main combustion chamber, which leads to rapid, highly stable combustion and significantly improved knock mitigation characteristics. This enables the use of a higher compression ratio and in testing, up to a 10% reduction in fuel consumption has been measured.

“We have also used the opportunity during the pandemic to further develop the cold-start and emissions performance,” continued Cooper. “Through careful development, we’ve been able to engineer a system that operates under these conditions without requiring a second ignition source, enabling the system to be applied to existing cylinder heads without the requirement for costly re-engineering. We have adapted an MJI-equipped production engine to start, run and perform reliably at -8°C with equivalent catalyst light-off capability to conventional spark ignition. This is very encouraging, and we’ll be continuing development to lower this figure substantially.”

Cooper stressed that the key to maximizing the benefits of MJI is to understand the vehicle manufacturer’s requirements and develop the correct combustion strategy accordingly. “Our experience of integrating these systems means we can tailor MJI to many different applications, from low-cost hybrid ICE to downsized, high specific power engines or even to heavy-duty gas engines. While the engineering effort to integrate the MJI system has been simplified, other engine systems need to be further optimized in order to gain the largest benefits, which might include higher compression ratio, revised inlet camshaft profile and re-matching of the boosting system. A whole system engineering approach is the way to get the best from MJI.”

The company says it is now working on the development of a demonstrator engine to showcase the technology’s potential in applications between 80kW to 120kW.