The Mercedes-Benz powertrain plants in Germany have started production of key components for its battery-powered eActros. The components – including the e-axle and battery packs, which are produced and assembled at the plants in Gaggenau, Kassel and Mannheim – will be used for the series production of the eActros, which will begin at the Mercedes-Benz plant in Wörth on October 7, 2021.

Yaris Pürsün, head of Global Powertrain Operations at Daimler Truck, said, “The launch of component production for the first series-produced all-electric truck bearing the Mercedes star is of great significance for us. Because of our battery packs, electric axle and drive system components, we are extensively involved in making the eActros a vehicle of Mercedes-Benz quality that will be locally carbon neutral out on the road.”

The Competence Centre for Emission-free Mobility (KEM) in Mannheim is assembling complete battery packs and undertaking pack function tests. The pack for the eActros consists of six individual battery modules. A completely assembled pack is around 220cm long, 75cm wide and 55cm high.

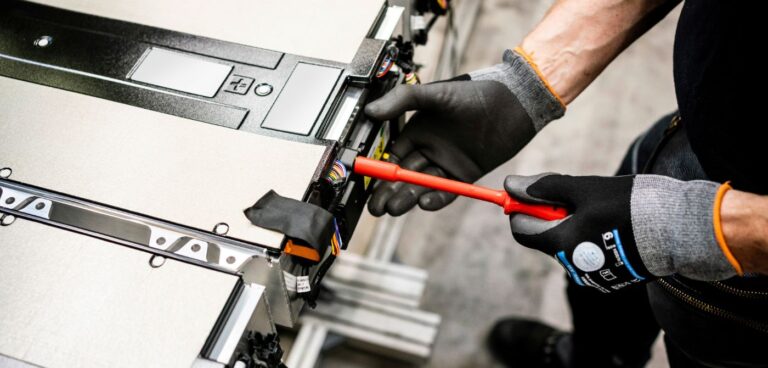

The Mercedes-Benz plant in Kassel assembles the complete electric axle, consisting of the axle bridge, the electric motor and the shiftable transmission elements. The Mercedes-Benz plant in Gaggenau supplies the transmission components for this. Before the e-axle is prepared for shipment, it is subjected to function and high-voltage tests. These tests examine electrical safety and noise properties.

Mercedes-Benz’s Gaggenau plant uses cutting-edge manufacturing techniques to produce transmission-related mechanical components and the associated housings. The range of components produced at the Mercedes-Benz plant in Gaggenau extends from a planetary gear with an outside diameter of 57mm to a drive wheel with an outside diameter of 365mm and a raw component weight of over 40kg. A total of 10 transmission parts and three housing components are supplied to the Mercedes-Benz plant in Kassel, where e-axle assembly takes place.